SAK ABRASIVES LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SAK ABRASIVES LTD

Creepfeed Grinding Wheel

Specially formulated porous bond systems to rough and finish a variety of materials in a single pass

Used to grind difficult to machine alloys requiring high stock removal rates for extremely deep forms, high speed grinding, high material removal rates, and reduced grinding temperatures. It us used in turbine blades, gears, broaches, and aerospace.

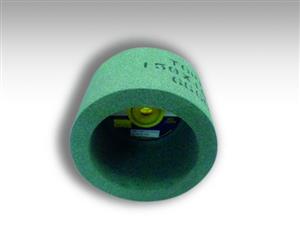

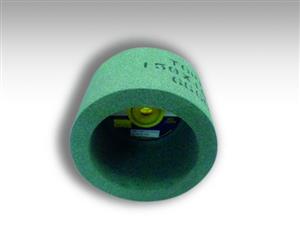

Toolroom Grinding Wheel

Remove that last micron of metal to obtain a finish as smooth as silk.

Typical applications are in the grinding of cutting tools like drills, reamers and milling cutters, surface grinding and cylindrical grinding. In these, the surface finish is of high quality and visual appearance. There is also less heat generation on the component and no burn marks. It is mainly used for dry grinding applications, without the usage of coolants. The types of tool room grinding surfaces are plain wheel, cup wheels, and dish wheels.

Offhand Grinding Wheel

Reduce operator fatigue and increase wheel life in one shot

“Off hand grinding” means the grinding of any material or part which is held in the operator’s hand. Also known as freehand grinding. Used in bench, pedestal and portable grinders for stock removal, tool sharpening, and smoothening of weld seams

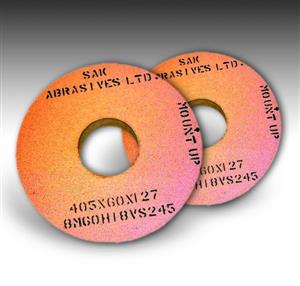

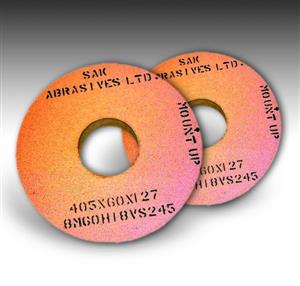

Centreless Grinding Wheel

A high performance grinding solution for a range of components, materials and sizes with an unmatched versatility.

It is a machining process that uses abrasive cutting to remove material from a work piece, which is secured between two rotary grinding wheels, and the speed of their rotation relative to each other, determines the rate at which the material is removed from the work piece. It is commonly used in the grinding of bearings, bars, taps, drills and a range of auto parts.

Cylindrical Grinding Wheel

Generate perfectly sized parts in a flash

Used in O.D. grinding of gear shafts, splined shafts, transmission shafts, valves, plunger pins, eye bolts, bearing races, etc. In this operation, the external or internal cylindrical surface of a work piece is ground. In external cylindrical grinding, or centre-type grinding, the work piece rotates and reciprocates along its axis although for large and long work parts, the grinding wheel reciprocates.

In internal cylindrical grinding, a small wheel grinds the inside diameter of the part. The work piece is held in a rotating chuck in the headstock and the wheel rotates at very high rotational speed. In this operation, the work piece rotates and the grinding wheel reciprocates.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.