SAI SURFACE COATING TECHNOLOGIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SAI SURFACE COATING TECHNOLOGIES

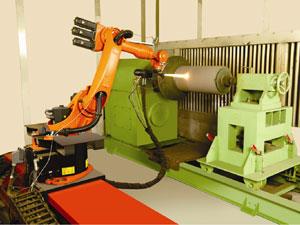

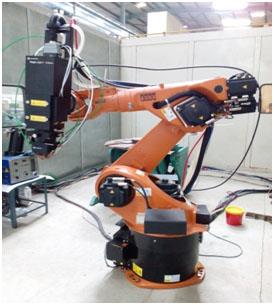

Thermal Spray Coating

IMPORTANCE OF THE SURFACE MODIFICATON TEHNIQUES:

In the modern Industrial world, engineering components are prone to more rapid surface degradation due to mechanisms such as wear, oxidation, corrosion or failure under an excessive heat load. As a consequence, in an effort to achieve enhanced performance in terms of productivity, efficiency etc., surface modification technologies have been attracting a great deal of attention as they present a cost-effective way to combat degradation modes such as above without sacrificing the bulk properties of the component material. Thermal spraying is one of the most versatile coating technique and finds wide ranging applications in numerous industry sectors.

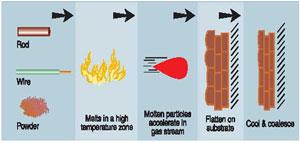

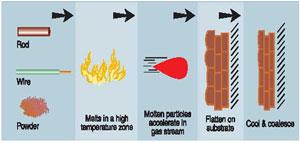

THERMAL SPRAY COATING PROCESS

In the thermal spray coating processes, electrical, chemical or mechanical energy is used to produce a high velocity gas jet. The coating material is introduced into this gas jet, usually in powder form. Particle-gas interaction lead to heat and momentum transfer from the gas jet to the particles and these accelerated particles are sprayed onto the substrate surface. On impact, thermal and kinetic energies of the particles are used for the formation of splats. These splats adhere to the substrate, and subsequently to each other to form the coating by this thermal spray coating technique.

BENEFITS OF THERMAL SPRAY COATINGS

DIRECT COST SAVINGS

- Very dense coatings (porosity less than 1%)

- No problem of hydrogen embrittlement like Hard chrome platting

- Increase in life of component.

- Reduction in maintenance costs.

- Decrease in equipment downtime.

- Increase in operating efficiency.

- Use of less costly material for bulk of component.

DESIGN IMPROVEMENTS

- Utilization of surface design engineering.

- Extending operating range of equipment.

- Improvement of manufacturing methods.

- Use of less dense base material.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.