SAI SURFACE COATING TECHNOLOGIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SAI SURFACE COATING TECHNOLOGIES

Thermal Spray Coating

IMPORTANCE OF THE SURFACE MODIFICATON TEHNIQUES:

In the modern Industrial world, engineering components are prone to more rapid surface degradation due to mechanisms such as wear, oxidation, corrosion or failure under an excessive heat load. As a consequence, in an effort to achieve enhanced performance in terms of productivity, efficiency etc., surface modification technologies have been attracting a great deal of attention as they present a cost-effective way to combat degradation modes such as above without sacrificing the bulk properties of the component material. Thermal spraying is one of the most versatile coating technique and finds wide ranging applications in numerous industry sectors.

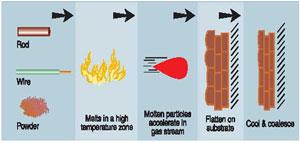

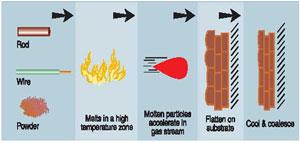

THERMAL SPRAY COATING PROCESS

In the thermal spray coating processes, electrical, chemical or mechanical energy is used to produce a high velocity gas jet. The coating material is introduced into this gas jet, usually in powder form. Particle-gas interaction lead to heat and momentum transfer from the gas jet to the particles and these accelerated particles are sprayed onto the substrate surface. On impact, thermal and kinetic energies of the particles are used for the formation of splats. These splats adhere to the substrate, and subsequently to each other to form the coating by this thermal spray coating technique.

BENEFITS OF THERMAL SPRAY COATINGS

DIRECT COST SAVINGS

- Very dense coatings (porosity less than 1%)

- No problem of hydrogen embrittlement like Hard chrome platting

- Increase in life of component.

- Reduction in maintenance costs.

- Decrease in equipment downtime.

- Increase in operating efficiency.

- Use of less costly material for bulk of component.

DESIGN IMPROVEMENTS

- Utilization of surface design engineering.

- Extending operating range of equipment.

- Improvement of manufacturing methods.

- Use of less dense base material.

Detonation Spray Process

Detonation Spray system used to develop dense ceramic and carbide coatings for wear resistant coatings for Aero engine, Power, Paper, Oil & refinery Sectors.

Process description

In Detonation spray system, an explosive high temperature flux of gas mixtures (Acetylene and Oxygen) is used as a source for heating, accelerating and spraying the powder particles. The high temperature, high velocity gas products of the detonation melt the particles and accelerate them sufficiently so that they emerge from the gun at supersonic velocities depending upon the material being sprayed and its powder size characteristics. The resulting high velocity impingement of the particles on the substrate yields very dense coatings with excellent adhesion.

This technology was developed and transferred by Advanced Research centre for powder metallurgy and new materials (ARCI), HYDERABAD.

Silent Features

- Coatings are very hard, clean and dense

- Coatings has low compressive stresses

- Coatings has very high bond strength

- Coating characteristics are superior than Flame spray coatings, Wire arc and Plasma spray coatings

Typical Coatings

- Anti - Wear Coatings

- Anti - Corrosion Coatings

- Metallic Coatings

H.V.O.F. Process

HVOF system used to develop wear resistant coatings for Aero engine, Power, Paper, Oil & refinery Sectors.

Process description

In High Velocity Oxy Fuel (HVOF) Spray System, Continuous combustion of the oxygen and fuel gas occurs in the combustion chamber and the resulting hot, high pressure gas is allowed to expand and accelerate through orifices into the nozzle. A carefully measured flow of powder is introduced axially into the nozzle, allowing sufficient heating and acceleration of the powder particles. The powder is heated and accelerated by the products of the combustion, usually to temperatures above its melting point and to velocities approaching supersonic velocities.

Silent Features

- Coatings are very hard, clean and dense

- Coatings has low compressive stresses

- Coatings has very high bond strength

- Coatings has high surface finish

- Coating characteristics are superior than Flame spray coatings , Wire arc and Plasma spray coatings

Typical Coatings

- Anti - Wear Coatings

- Anti - Corrosion Coatings

- Metallic Coatings

Plasma Spray Coating System

The plasma spray coating system is versatile process in thermal spray coating systems and by using this system ceramics, carbides, metals and plastics can be applied onto base materials for wear and corrosion protection, electrical insulation, thermal insulation, repair, and restoration.

Plasma Spray Coating Process description

In plasma spray coating system, an electric arc created between two fixed electrodes. Process gasses (argon, nitrogen, hydrogen, helium) flows around the cathode and through the anode which is shaped as a constricting nozzle. The plasma is initiated by a high voltage discharge which causes localised ionisation in this plasma spray coating. Powder is fed into the plasma flame most commonly via an external powder port mounted near the anode nozzle exit. The powder is so rapidly heated and accelerated to deposit on work piece.

Silent Features

- Ability to deposit refractory materials like Zirconia and Tungsten etc.

- Coating characteristics are superior than Flame spray coatings and Wire arc spray coatings

- Coatings have high surface finish

- Excellent control of coating thickness

Typical Coatings

- Thermal Barrier Coatings

- Electrical Insulation Coatings

- Abradable coatings

- Wear Resistant Coatings

- Anti -Corrosion Coatings

- Metallic Coatings

Electric Arc Wire Spray System

The main advantage of Powder flame spray coasting over the wire flame spray coating is that a much wider range of materials can be easily processed into powder form giving a larger choice of coatings such as metals, alloys, carbides, polymers and ceramic powders.

Process description

In Flame spray coatings system, Material in powder/wire/rod form is melted in a flame (oxy-acetylene flame most common, Flame temperature nearly 3,000�C) and atomized using compressed air to form a fine spray in this flame spray coating process. When the spray contacts the prepared surface of a substrate material with particle velocity of 80 m/s, the fine molten droplets rapidly solidify forming a coating.

Powder/wire/Rod Flame Spray Coatings System

Spray And Fuse Process

In Plasma Ion Nitriding, excellent control on process and metallurgical repeatability will be achieved over conventional nitriding processes such as Bath and Gas Nitriding processes.

Process description

In a vacuum, high voltage electrical energy is used to form the plasma, through which nitrogen ions are accelerated to impinge on the workpiece. The ion bombardment heats the workpeice, cleans the surface and provides active nitrogen.

HORIZONTAL TIG WELDING EQUIPMENT

This Equipment very useful for carrying narrow groove welding to join thick sleeves, long tubes and to carry cladding on large components. The welding principle of this equipment is Tungsten Inert Gas Welding (TIG) principle.

Laser Cladding And Hardening Processes

Laser cladding process utilizes a laser source to create a melt pool of the base material and cladding material is introduced into this melt pool in powder form. The energy of the laser melts the cladding material also to form alloying zone between base material and clad material resulting to a metallurgical bonding with good control on required dilution rates.

Laser hardening process is environmental friendly process which will produce very effective hardening layer compare to conventional hardening processes.

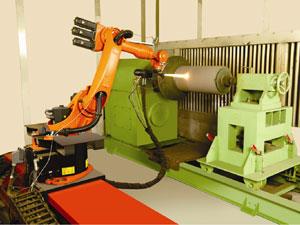

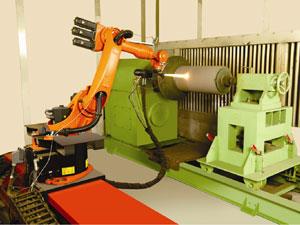

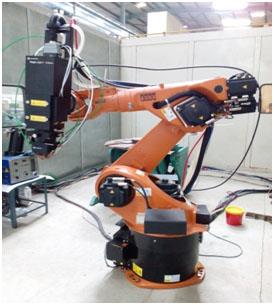

Laser cladding & Hardening Facility at SSCT:

ADVANTAGES OF LASER CLADDING PROCESS:

1. Lower dilution levels

2. Metallurgical Bond

3. Minimal heat effected Zone

4. Minimal part distortion

5. Reduced post processing

6. Highly repeatable process

P.T.A. Welding Process

The main advantage of PTA Welding process is low dilution levels than TIG & MIG welding processes.

Process Description

In PTA welding, two DC power supplies are used to first establish a pilot arc (non-transferred arc) between the tungsten electrode and the anodic nozzle and then a transferred arc between the tungsten electrode and the workpiece. The pilot arc is struck by an High Frequency device and the plasma gas flowing around the cathode is ionized at the electrode tip. When the transferred arc is ignited, the workpiece becomes part of the electrical circuit and the plasma arc is directed and focused through the torch orifice into the workpiece. Powder is metered, under a positive pressure of Argon flow, from the bottom of the torch into a pool of molten metal on the workpiece surface.

Aero Space

The design of an aero-engine is subject to the principle of a high power-to-weight ratio and demands the highest possible performance of each component. Today, applications in the aero-engine industry represent an important part of the market for thermal spray coatings. In the aircraft, over 75 percent of engine parts are coated with some type of protective layer.

Our coatings in aero-engine have the functions like Thermal barriers, High temperature corrosion resistant, Abradable and adhesive wear resistant.

Applications :

- Fan blade clappers

- Stator blades

- Flame tube locations

- Combustion cans

- Combustion vanes

- turbine blades

- Turbine vanes

- sectors of turbine rings

- Nozzles

- Jet engine shrouds

- Aircraft landing gear

- Turbine shafts

- Seal Rings

- closing pistons

- support bearings

- Labyrinth

- Centre Bearing Housing

- Fuel rod mandrels

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.