SAI SURFACE COATING TECHNOLOGIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SAI SURFACE COATING TECHNOLOGIES

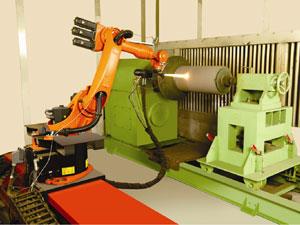

Plasma Spray Coating System

The plasma spray coating system is versatile process in thermal spray coating systems and by using this system ceramics, carbides, metals and plastics can be applied onto base materials for wear and corrosion protection, electrical insulation, thermal insulation, repair, and restoration.

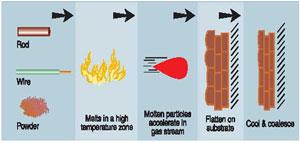

Plasma Spray Coating Process description

In plasma spray coating system, an electric arc created between two fixed electrodes. Process gasses (argon, nitrogen, hydrogen, helium) flows around the cathode and through the anode which is shaped as a constricting nozzle. The plasma is initiated by a high voltage discharge which causes localised ionisation in this plasma spray coating. Powder is fed into the plasma flame most commonly via an external powder port mounted near the anode nozzle exit. The powder is so rapidly heated and accelerated to deposit on work piece.

Silent Features

- Ability to deposit refractory materials like Zirconia and Tungsten etc.

- Coating characteristics are superior than Flame spray coatings and Wire arc spray coatings

- Coatings have high surface finish

- Excellent control of coating thickness

Typical Coatings

- Thermal Barrier Coatings

- Electrical Insulation Coatings

- Abradable coatings

- Wear Resistant Coatings

- Anti -Corrosion Coatings

- Metallic Coatings

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.