SAI SURFACE COATING TECHNOLOGIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SAI SURFACE COATING TECHNOLOGIES

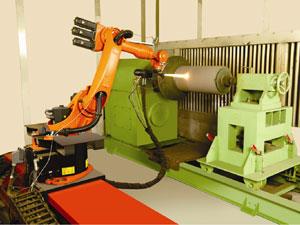

Detonation Spray Process

Detonation Spray system used to develop dense ceramic and carbide coatings for wear resistant coatings for Aero engine, Power, Paper, Oil & refinery Sectors.

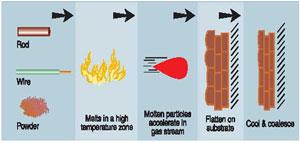

Process description

In Detonation spray system, an explosive high temperature flux of gas mixtures (Acetylene and Oxygen) is used as a source for heating, accelerating and spraying the powder particles. The high temperature, high velocity gas products of the detonation melt the particles and accelerate them sufficiently so that they emerge from the gun at supersonic velocities depending upon the material being sprayed and its powder size characteristics. The resulting high velocity impingement of the particles on the substrate yields very dense coatings with excellent adhesion.

This technology was developed and transferred by Advanced Research centre for powder metallurgy and new materials (ARCI), HYDERABAD.

Silent Features

- Coatings are very hard, clean and dense

- Coatings has low compressive stresses

- Coatings has very high bond strength

- Coating characteristics are superior than Flame spray coatings, Wire arc and Plasma spray coatings

Typical Coatings

- Anti - Wear Coatings

- Anti - Corrosion Coatings

- Metallic Coatings

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.