RSB TRANSMISSIONS I LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to RSB TRANSMISSIONS I LTD.

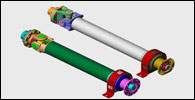

Propeller Shaft

RSB is a vertically integrated Propeller Shaft Solution provider, enjoying the largest market share in India. To enhance its in-house technical capabilities and overall productivity, RSB has developed a technical collaboration with Eugen Klein GmbH,Germany for acquiring technical know-how in designing, processing and testing.

The Propeller Shaft Manufacturing program covers more than 65 unique part designations. RSB is focused on catering to the present & futuristic commercial vehicle power transmission requirements and meeting the stringent quality norms. The six manufacturing plants set up at 4 locations are functioning to assist Auto OEM’s for Propeller Shaft solutions targeted towards regular production as well as after market requirements.

Manufacturing

A range of new generation Propeller Shafts, offerings un-beatable Value & Reliability through:

In-House component manufacturing with SPM's for all critical machining

In-House Phosphate facilities and sophisticated Paint Shop

Latest generation 3 Plane Balancing machine with digital PLC

Fully automated line for manufacturing Cross & Bearing Cup with on-line SPC

In-house metallurgical lab to ensure validated raw material inputs

In-house testing & validation facility for the assemblies

Engineering

RSB has designed and developed new Propeller shafts that are lighter, more cost effective, achieving improved performance levels of torque transfer. RSB provides validated newer designs extended to cover several models of Commercial Vehicles, Trucks, and Buses by conducting extensive field trials under varied terrains and load conditions. RSB ensures competitive edge by providing re-designed Roller Bearings, fully enclosed seals, Serration joints, RILSAN® surface coating treatment. The other features include

Heavy Duty Center Bearing Assembly

Cross Assembly Multi-Lip Sealing

Increased Deflection Angle between forks

Spline Profile

Metallic Dust Jacket with Neoprene Seal etc

Axles

Axles are one of the most significant products offered by RSB. It has a staggering capacity to manufacture 2,00,000 Axles/year. There are plans to enhance the capacity by 30% to cater to the export market. Well-equipped manufacturing lines have been dedicated to develop a variety of Axle.

Manufacturing

RSB is efficiently producing trailer axles, dummy axles, LCV front axles, banjo axles, tractor axles. Initially the products were manufactured to suit customer designs, RSB now provides axle solutions with self indigenous design that can universally match the varied customer needs. The integrated engineering plant has been facilitated with state-of-the-art technology to design, develop and validate the axles. The facilities include Induction Heating, Sub-merged Arc welding, Flexible designed SPM's, CNC Turning / Vertical Machining Centers and Painting.

Engineering

The plants have comprehensive engineering and manufacturing processes for the Customer designed Axles. RSB also ensures the efficacy by providing customized solutions with its own design. I-Design, RSB's engineering facility, closely works with the customers to assist in activities related to Design, FEA, Prototyping, Testing & Field Trials.

Product Range & Specifications

Dummy Beams

Axle Load : 10 / 12 / 14 & 16 Tonnes

Banjo Beams

Axle Loads : 8 / 10 Tonnes

LCV Front Axles

Upto 1.2 Tonnes

Tractor Front Axles

Range : 35Hp to 55Hp Tractors, Mechanical & Power Assisted

Transmission Components

RSB's Gear Transmission units provide in-depth product support to prospective OEM clients based on its vast industry experience and expertise. It manufactures an extensive range of fully finished gears at two of its plants that are strategically located to cater to diversified industry sectors inclusive of Commercial Vehicles, Passenger Cars, Tractors, Pump OEM's. RSB is renowned for its customer services such as, fast turn around and individual attention to complex orders.

Manufacturing

The plants have organized amenities for Gear Cutting, Heat Treatment, Finishing and Final testing under one roof, complying with DIN Class 7/9. Advanced CNC Gear Cutting Machines for Hobbing, Shaving, Shaping and Sealed Quench Furnace for Carburising & Carbo-Nitriding have been installed.

The equipments also include a complete package of Metallurgy & Metrology comprising CNC Hoffeler Gear Tester, Carl Zeiss Microscope & Zwick Micro Hardness Tester.RSB identifies the requirements of the customers and accordingly establishes Manufacturing Cells to ensure consistent quality with on-time deliveries.

Product Range & Specifications

Spur & Helical Gears

30 to 310mm dia, Module 1 - 8

Geared Shafts

600 mm length

Sleeves Plain

up to 250 mm dia

Sleeves Broached

up to 120 mm dia

Aluminium Castings

RSB offers precision machined Aluminium castings to domestic as well as export markets. RSB has been assisting any intricate casting ranging from 0.5 Kg aluminum component to 8.0 Kg aluminum component. RSB has been successfully managing the complete supply chain program for a reputed US based OEM and supplies around half a million components annually. The scope includes local warehousing in US and daily online supplies. The existing export supply agreement has been renewed for the next program that reaffirms the faith of the customers.

Manufacturing

RSB has integrated backwards to produce the aluminium castings in High Pressure Die Casting.

The machining lines have been established according to the products offered to the customers. All the plants are with modern and high-speed Machining Centers integrated with online SPC for the high volume production lines, CNC Presetter and Carl Zeiss CMM. The components are 100% leak tested and match the stringent quality requirements of the export customers ensuring high quality standards.

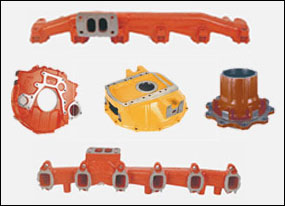

Ferrous Castings

RSB manufactures Ferrous Castings as per customer design & specifications at its manufacturing plants located at Jamshedpur & Pune. It offers and supplies a wide range of products to leading OEM’s like Cummins.RSB completely manages the supply-chain from Castings procurement stage to the supplies and also conducts periodical supplier audits.

An in-house Quality Control has been ensuring high quality standards. The vast experience of the professionals and the expertise of RSB has been the key to manufacturing cost-effective and reliable Automobile Parts.

Manufacturing

This is equipped with modern machining lines and robust process engineering to meet the quality and volume requirements. The machining lines are also equipped with various testing facilities to carry out in house test for cracks, hardness, metallurgical properties and leaks among others.

Product Range & Specifications

Typical machined castings range from 1kg to 50kg and the current range includes the following:

Exhaust Manifolds

Fly Wheel Housings

Clutch Housings

Main Bearing Cap

Hubs

Gear Box Cases

Oil Cooler Covers

Running Gear System

RSB manufactures Running Gear Systems like Axle, Fifth Wheel Coupling, King Pin and Landing Leg, which are designed, developed, tested and validated by its in house R&D division I-Design. Our Fifth Wheel Coupling design is at par with latest European models. RSB offers organized after sales service network across major cities in India.

Manufacturing

The manufacturing plants are armed with equipments like Robotic Welding in the 5th wheel, King Pin, Submerged Arc Welding, Shot blasting, 400 hrs SST, etc., to ensure cost-effectiveness, better quality and durability of the products.

Construction Equiment Aggregates

RSB is a forerunner in the Construction Equipment Aggregates industry in India. It has set up three modern manufacturing facilities at Jamshedpur, Dharwad and Chennai.

RSB has reached significant milestones in the exports market over past few years. The services and the efforts are being reflected by the faith of our international customers. Today, RSB is serving as a single source to many overseas customers and manages their supply chain.

Manufacturing

The manufacturing units have been empowered by some of the most contemporary tools and techniques that enable better productivity. Technology and facilities such as CNC Laser Cutting, Plasma Cutting & Oxy. Cutting, Robotic Welding, CNC Floor Boring Machines, Vertical Boring Machines, Machining Centers, etc have been installed.

Engineering

Amenities like process engineering for the aggregates have been established. Services related to Special Designs & Engineered Fixtures for Welding & Assembly of these aggregates have also been created. RSB is deeply involved in value engineering exercises with the Customers to reduce the overall costs & realize the quality goals.

Product Range & Specifications

Hydraulic Excavators:

Main Frame, Track Frame, Arms, Booms, Buckets

Backhoe Loaders:

Chasis, Boom, Arm, Slider Frame, Axle, Loader & Hoe Bucket

Front End Loader:

Front Frame, Rear Frame, Lift Arm, Loader Bucket, Oscillation Cradle, Dump Lever

Forging

RSB manufactures forging components with state-of-the art technology and equipment to cater to the most stringent quality standards of forged components for domestic and export customers. This facility will be the backbone of the group’s forging requirements, and will also cater to OEM customers of the country.

Manufacturing

Forging Unit is equipped with two forging lines, supported by an on-line heat treatment facility, state-of-the-art metallurgical laboratory and a tool room. This facility has recorded and maintained the highest productivity in the industry, for similar type of manufacturing lines.

Product Range & Specifications

This facility manufactures all kind of forged components like :

Flange Yoke

Short Fork

Long Fork

Axle Components

Steering knuckles

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.