Distillery Plant

Production & consumption of alcohol is an age old practice. But with time, the usage areas as well as production techniques have gone through a major transformation. Apart from potable purposes, alcohol today finds application in a varied mix of industrial areas.

And with state-of the-art technology, we now have techniques & systems that bring out much higher quality of the product while effectively lowering production costs.

The process of distillation is one with slow dynamics and is accompanied by side streams, making it essential to have a carefully planned and designed control system.

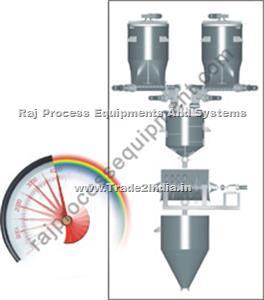

47102.jpg)