PRESSLINE INDIA P. LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PRESSLINE INDIA P. LTD

Sapphire Plus

Salient Features :

Book Clamp easily adjustable with handle and applies uniform pressure on each book.

Spine preparation consists of a combination of notching tool and dust cutters. The height adjustable roughening teeth ensure effective exposure of the paper fiber.

Hot Melt Roller application system equipped with a roller and scrapper mechanism, the glue film thickness is controlled by adjustable Doctor blades.

Side gluing by a separate tank with oblique discs ensure uniform glue application on the sides of the books.

Nipping Station presses the spine & sides of the book with motorized forward & reverse mechanism. The duration of nipping applied pressure is determined by pneumatic timer.

Auto cycle on time, Nipping on time & Delivery duration time are adjustable and controlled by pneumatic timers

Sapphire

Salient Features :

Book Clamp easily adjustable with handle and applies uniform pressure on each book.

Spine preparation consists of a combination of notching tool and dust cutters. The height adjustable roughening teeth ensure effective exposure of the paper fiber.

Hot Melt Roller application system equipped with a roller and scrapper mechanism, the glue film thickness is controlled by adjustable Doctor blades.

Nipping Station presses the spine & sides of the book with motorized forward & reverse mechanism. The duration of nipping applied pressure is determined by pneumatic timer.

Auto cycle on time, Nipping on time & Delivery duration time are adjustable and controlled by pneumatic timers

Pearl

Salient Features :

Book Clamp easily adjustable with handle and applies uniform pressure on each book.

Spine preparation consists of a combination of notching tool and dust cutters. The height adjustable roughening teeth ensure effective exposure of the paper fiber.

Strip Type milling is optional

Hot Melt Roller application with two rollers applicators rotating in forwards direction and the third roller counter rotating fitted with heater smoothen the spine adhesive.

Side gluing by a separate tank with oblique discs ensure uniform glue application on the sides of the books. However production without side gluing is also possible.

Nipping Station presses the spine & sides of the book with motorized forward & reverse mechanism. The duration of nipping applied pressure is determined by pneumatic timer.

Auto cycle on time, Nipping on time & Delivery duration time are adjustable and controlled by pneumatic timers

Book Star

Salient Features :

Book Clamp easily adjustable with handle and applies uniform pressure on each book.

Spine preparation consists of a combination of notching tool and dust cutters. The height adjustable roughening teeth ensure effective exposure of the paper fiber.

Strip Type milling is optional

Hot Melt Roller application system equipped with a roller and scrapper mechanism, the glue film thickness is controlled by adjustable Doctor blades.

Nipping Station presses the spine & sides of the book with motorized forward & reverse mechanism. The duration of nipping applied pressure is determined by pneumatic timer.

Auto cycle on time, Nipping on time & Delivery duration time are adjustable and controlled by pneumatic timers

Ruby Mini Binder

Salient Features :

Book Clamp easily adjustable with handle and applies uniform pressure on each book.

Spine preparation consists of a combination of notching tool and dust cutters. The height adjustable roughening teeth ensure effective exposure of the paper fiber.

Hot Melt Roller application system equipped with a roller and scrapper mechanism, the glue film thickness is controlled by adjustable Doctor blades.

Nipping Station presses the spine & sides of the book with motorized forward & reverse mechanism. The duration of nipping applied pressure is determined by pneumatic timer.

Auto cycle on time, Nipping on time & Delivery duration time are adjustable and controlled by pneumatic timers

Diamond Series

Description / Specification of Diamond Series

We are involved in offering a wide range of Diamond Series to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Diamond Series. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

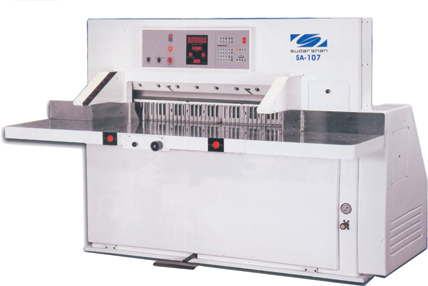

Sudarshan Programmable Paper Cutting Machine

Salient Features

Radial, streamline, box type design of parts & high grade material of main parts, gives rigidity & long life to machine.

Best quality materials are used to withstand wear & tear, strain & stress.

Positive drive hydraulic clutch ensures quick action, less wear & tear & long clutch system life.

Hydraulic clutch device for maintenance free & slippage free operation.

Telescopic double pressure cylinder with almost pipe less powerpack.

Pressure knob for adjustment of pressure from 200 kgs to 4500 kgs.

Graduated back gauge knobs for horizontal & vertical, right angle setting backgauge.

Programme Controlled Air Table for easy movement of bulky stock.

A.C. Drive System for smooth & uniform movement of backgauge.

Ball screw & L.M. Guide for uniform & precise movement of backgauge.

S.S. Sheet on entire main table & side table.

Slot closing tape to avoid paper tripping while movement

False clamp system ensure cutting of soft material without clamp impression.

Magic Cut Paper Cutting Machine

home � other products � sudarshan � magic cut paper cutting machine

'SUDARSHAN' PROGRAMMABLE PAPER CUTTING MACHINE

'SUDARSHAN' MAGIC CUT PAPER CUTTING MACHINE (Accurate-Reliable-Safe)

Magiccut version has a large no. of job storing capacity with 99 cutting steps in each job. Magiccut has alpha numeric support to describe each and every job name wise or number wise. Excellent storage arrangement is provided.

Online graphic support is provided to identify the cut layout of programmed data. Graphics get updated while each and every cut which makes complex cutting simple and easy. Offline programming of job is provided to save time in job making.

Monitoring system with the help of function configuration is provided for easy assessment of fault.

Job data can be programmed with Ten key operation, Cut & store , and Tabulation method. There are many shortcut keys provided to access this function with all necessary support like calculator, insert data, delete data, copy data, correction of data, cm/inch selection.

High speed back gauge position @200 mm/sec result into higher productivity. 0.001cm calibration accuracy for better and accurate cutting operation.

Paper Cutting Machine

Salient Features

Heavy duty, Rigid construction provides stable performance & long life. Best quality materials are used to withstand wear & tear strain & stress.

Positive drive hydraulic clutch ensures slippage free & maintenance free cut operation.

Telescopic double pressure cylinder within single tank with almost pipe less power pack. Pressure knob to adjust the desire clamping pressure.

Two rows infra-red curtain with row selection in front of cutting zones ensures 100% safety while cutting.

Rigid guiding system for back gauge movement ensure perfect parallel & right angle cutting of paper.

Main table with Air nozzles for easy movement of bulky material. Side tables covered with air nozzles.

Overload safety bolt to avoid severe mechanical damage.

Flush type, dust proof, feather touch keyboard for smooth operation of program unit.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.