POLYDRIVE

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to POLYDRIVE

Timing Belt Suppliers And Exporters In India

Timing belts make less noise compare to chain belts and gear belts and has high transmission capacity and efficiency. Timing belt is widely used for wood processing, mining, packing pipeline, weaving and many other machines. This belt doesn't require lubrication hence its maintenance free and able to deal with storm stress. Replacement of Timing Belts is time and cost saving than the alternative.

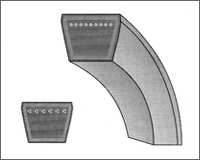

Wedge Belts And Fhp And M Section

Wedge Belts have been the result of continuous thrust by the manufacturers and the users on higher power transmissions with reduction in space requirements. Wedge belts can transmit high power to extent of 1.5 to 2 times the classical belts with same top width this has been achieved by the dimensional changes, part from better cord constructions used and the optimum placing of the cord line which provides the best support to the cord while in motion. For efficient performance of wedge drives it is essential that the proper tension be maintained in the drives, failure to maintain the same will render the purpose of wedge belts ineffctive.

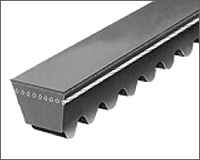

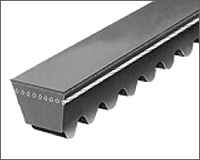

Cogged Belt Manufacturers Suppliers And Exporters In India

Cogged belts are suitable for all industrial applications, particularly where small or sub-minimal sheave diameters are required.

We are one of the leading Cogged Belt Manufacturers & Supplier in Mumbai, India. Our main aim is to offer products of best quality so that customers can achieve optimum production, efficiency, minimum operating cost.

Hexagonal (Double) V Belt

V Belt 57691.jpg)

Both bottom and top faces can be used for lower transmission. Best suited to multi pulley drive, being highly flexible. Heat & Oil resistant plus static conductive.

Features :

Suitable for drives where belts bend both ways on several pulleys.

Specially compounded base gives good flex fatigue resistance.

Designed for low heat build-up to extend belt life.

Ransmission Canvas Belting

Description / Specification of Ransmission Canvas Belting

We are involved in offering a wide range of Ransmission Canvas Belting to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Ransmission Canvas Belting. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Link Belts

The full depth of a V-section T-Link Belt is made up from 3 overlapping sections.

The belt is joined or broken by simply rotating the T-headed pins until they line up with the slots cut in a each link.

Although the pins go right through each link there is always clearance for them in the bottom of the V pulley

Commonly known as "Link Belts", which is a type of V-belt (it cannot be used on flat-belt drives), is widely used in industrial and marine applications. Although more expensive than ordinary V-belts it does have some important advantages.

Tyre Couplings

Polydrive Tyre couplings provide all the desirable features of an ideal flexible coupling, including Taper Lock fixing in India. The Polydrive Tyre coupling is a "torsionally elastic" coupling offering versatility to designers and engineers with a choice of flange combinations to suit most applications.

The flanges are available in either F or H version Taper Lock fitting or bored to size B.

With the addition of a spacer flange, the coupling can be used to accommodate standard distance between shaft ends and facilitate pump maintenance.

Rubber Conveyor Belts

Rubber Conveyor belts consist with a continuous loop of two or more pulleys or rollers to rotate them. The Rubber conveyor belts are used to convey items with irregular base or bags of product that would droop between rollers. The conveyor belt consists of two or more layer which is made up of rubber.

Many belts in general material handling have two types of layers. First one is the under layer of material which is to provide linear strength and shape called a carcass and other one is an over layer called the cover. The carcass is often a cotton or plastic web or mesh and the cover is made up of various rubber, plastic, silicone compounds considering by use of the belt.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

Belts 57687.jpg)

V Belt 57691.jpg)

57692.jpg)

Belts 57687.jpg)

57692.jpg)