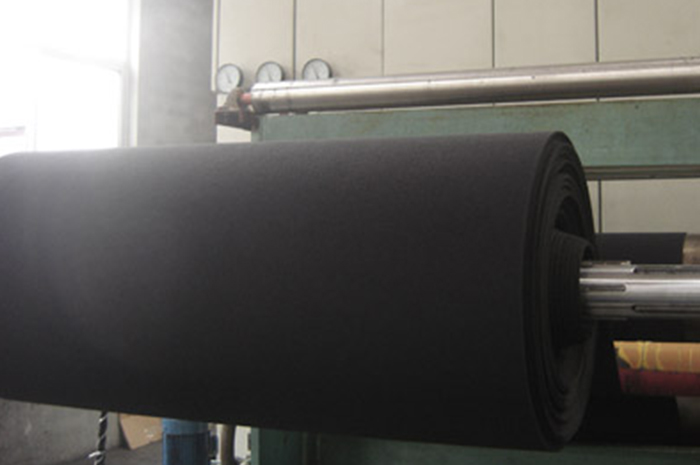

Garfleece Flexible Insulating Material

PRODUCT COMPOSITION

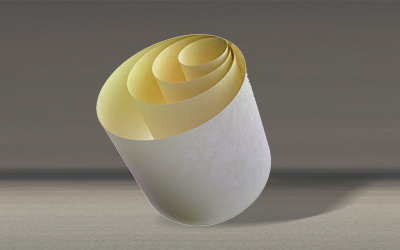

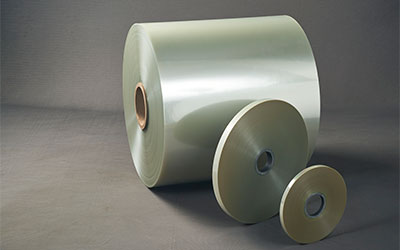

Polycom's GARFLEECE B (F) laminates are composites of polyester fleece on either side of Polycoster film glued together with excellent quality thermosetting adhesive. Polyester film's high electrical & mechanical strength are complemented by good impregnating properties of the polyester fleece.

ADVANTAGES

Excellent electrical and mechanical properties .

Excellent impregnating capacity.

Suitable for automatic insertion.

Protection against the influence of hydrolysis and chemical actions.

Saves on copper and steel for rated power.

High Flexibility

Insulation 72473.jpg)