POLYCOM ASSOCIATES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to POLYCOM ASSOCIATES

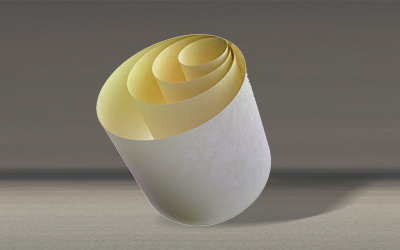

Prepregs Flexible Insulating Material

Polycom’s PREPREGS are made by coating/impregnating flexible materials (Nomex®, Non-woven or Fabric) with ‘B’ stage reactive coating of resin. Depending on backing material used; Prepregs belong to insulation class ‘E’ & ‘F’.

Prepregs are tack - free at room temperature but become tacky at 110°c to 130°c. These are converted to ‘C’ stage by heat energy & pressure to achieve good bonding between the copper conductor. The resin system depends on processing conditions of the customer, but usually epoxy resin is used.

ADVANTAGES

Highly flexible in supplied condition.

Good bonding capability due to the re-active stage of coating.

Favorable hardening times.

Excellent winding & trouble-free machining qualities.

Enhanced mechanical and dielectric strength.

Imports Good vibration resistance to Winding Coils

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

Insulation 72473.jpg)