POLYCOM ASSOCIATES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to POLYCOM ASSOCIATES

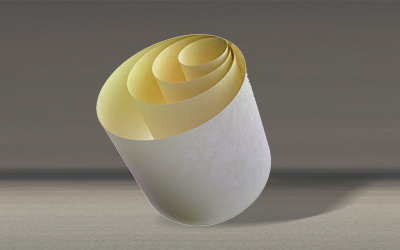

Garfleece Flexible Insulating Material

PRODUCT COMPOSITION

Polycom's GARFLEECE B (F) laminates are composites of polyester fleece on either side of Polycoster film glued together with excellent quality thermosetting adhesive. Polyester film's high electrical & mechanical strength are complemented by good impregnating properties of the polyester fleece.

ADVANTAGES

Excellent electrical and mechanical properties .

Excellent impregnating capacity.

Suitable for automatic insertion.

Protection against the influence of hydrolysis and chemical actions.

Saves on copper and steel for rated power.

High Flexibility

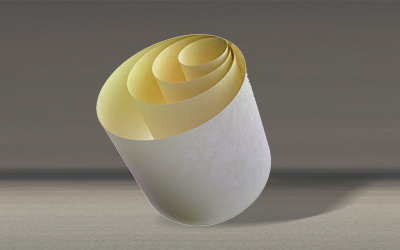

Garfleece (Saturated) Insulation

Insulation 72473.jpg)

Polycom's GARFLEECE (IMPG) laminates are composites of polyester film with resin impregnated non-woven polyester fleece on either side. These are glued together with superior adhesive : The polyester non-woven fleece with fully cures impregnated resin protects the polyester film at high temperatures against oxidation, hydrolysis & mechanical damages.

ADVANTAGES

High electrical & mechanical strength.

Protects polyester film at high temperatures.

Resistance to other impregnation agent.

Easy insertion.

High smoothness.

Remarkable Varnish Absorption

Garkon Insulation

Polycom's GARKON composites are of Nomex® paper laminated on either side of Polyimide® film. The lamination is achieved through high quality thermosetting adhesive. The excellent Mechanical, Thermal & Electrical values of Polyimide film are complimented with the very good chemical & Thermal properties of Nomex® Polycom's GARKON are produced in various combination.

ADVANTAGES

Have very good Electrical, Mechanical and Thermal properties

High dielectric strength even at high temperatures.

Good impregnating Capacity.

Suitable for automatic insertion.

Excellent Chemical Resistance.

Higher thermal endurance for prolonged periods.

Gartherm Flexible Insulating Material

Polycom's GARTHERM® Laminates are composites of Nomex® paper laminated on either side of Polyester Film using high quality adhesive. High electrical and mechanical strength of polyester film is complemented by high temperature resistance of the Nomex® Paper. Polycom's GARTHERM® are produced in various combination to cover various needs of electrical industries.

ADVANTAGES

GARTHERM® composites have very good dielectric and mechanical properties.

High chemical and solvent resistance.

Protects the influence of hydrolysis.

Suitable for automatic insertion.

Superior Varnish absorption & Flexibility for Uncalendered Composites Higher Thermal Endurance

Nomex

Nomex® Type 410 is a calendered insulation paper which offers high inheritent dielectric strength, mechanical toughness, flexibility and resilience. Also available in uncalendered variety (Type 411), for oil filled transform (Type 910).

ADVANTAGES:

Class H Insulation

Mechanical toughness and (in thime grade) flexibility

Inherent Di- Electric Strength

Unaffected by most solvents, acids & albalies

Compatible with varnishes, adhesives & transformer fluids

Gardicot

POLYCOM'S CARDICOT

Cardicot Consists craft paper coated with diamond shape epoxy resin on both sides with hightech process. which are in reactive 'B' stage and are tackfree at room temperature but become tacky at 120℃ to 130℃.

ADVANTAGES

Internal strengthening of coil for oil filled transformers as layer insulation.

Helps considerably in faster drying & filling as the liquid insulating agent will penetrate. the pressboard insulation completely in a short period.

Minimised dangers of partial discharges.

Prepregs Flexible Insulating Material

Polycom’s PREPREGS are made by coating/impregnating flexible materials (Nomex®, Non-woven or Fabric) with ‘B’ stage reactive coating of resin. Depending on backing material used; Prepregs belong to insulation class ‘E’ & ‘F’.

Prepregs are tack - free at room temperature but become tacky at 110°c to 130°c. These are converted to ‘C’ stage by heat energy & pressure to achieve good bonding between the copper conductor. The resin system depends on processing conditions of the customer, but usually epoxy resin is used.

ADVANTAGES

Highly flexible in supplied condition.

Good bonding capability due to the re-active stage of coating.

Favorable hardening times.

Excellent winding & trouble-free machining qualities.

Enhanced mechanical and dielectric strength.

Imports Good vibration resistance to Winding Coils

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

Insulation 72473.jpg)