PLAST PHARMA

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PLAST PHARMA

Cream Filling Machines

OUR CREAM FILLING MACHINE IS WIDELY USED FOR PRECISE QUANTITY FILLING FOR SEMI LIQUID PRODUCTS

FOR GREASE FILLING FRUIT JAM FILLING GULKAND FILLING

TECHNICAL SPECIFICATIONS

- SPEED :- 15 TO 35 CONTAINERS PER MIN

- MODEL :- GMP

- CAPACITY:- 5 GRAMS TO 125 GRAMS PER SINGLE STROCK PER FILL

- MOTOR 1/2 HP

- TYPE :- COMPLETE MECHANICAL (NO PNEUMATICAL)

AVAILABLE IN AUTOMATIC AND SEMIAUTOMATIC MODEL

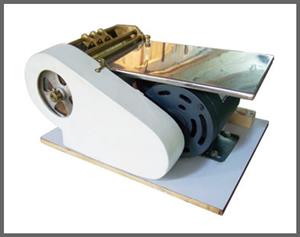

Band Sealer

Band sealer is used to pack/seal pouches from 2 gm to 7 Kg or as per customer's requirements

- Available size for :- up to 1 kg pouch, 3 kg pouch, 10 kg pouch

- 1 kg and 3 kg pouch sealer available in horizontal and vertical sealing options for better convenient

- Power Single phase AC with DC variable drive

- Speed :- up to 20-30 pouch /min

Shrink Packing Machine With L Sealer

Shrink packing machines are most common machines among all packaging machines.These are available with and without L SEALER for ease of packing

The L SEALER is used when packing speed required is hiugh about 10-15 shots per min.

It requires L type Shruink roll which should be according to the size of the product to be sealed

Shrink machines are available in std MS material as well as SS material for GMP stds. with sizes as below

6 x 6

8 x 8

10 x 10

12 x 12

14 x16

We also manufacture special size as per your requirements

Semi Automatic Ropp Capping Machine

Description / Specification of Semi Automatic Ropp Capping Machine

We are involved in offering a wide range of Semi Automatic Ropp Capping Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Semi Automatic Ropp Capping Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Auger Powder Filling Machine

Suitable for filling powder such as chilly,turmeric,tea,sugar,ayurvedic churna,masala,etc

In this machine, the powder is filled in the hopper provided for the same with quantity of 10-15 kgs,at once.

The powder is filled in the bottle or container os fixed volume just by pressing the foot switch provided on the machine

The volume of thepowder is set by electroniccontrol pannel on the machine

Normal accuracy is 1% of total volume

Ampule Sticker Labeling Machine

- Automatic ampule sticker labeling machine with ampule feeder

- For Ampules /small round bottles

- Available in regular horizontal model for high speed productions

- Speed up to 250-300 bottles/min

- Power ½ HP Single Phase

- Optional coder attachment for printing

- Custom made solutions for different bottles shapes

Sigma Mixer Kneader

We manufacture sigma mixers-kneaders for soap industries, chemical industries with and without cooling jackets, sigma mixers with vaccum for pharmaceutical applications

Laboratory model sigma mixer-Kneader

SIGMA MIXER/KNEADER FOR VARIOUS APPLICATIONS

- Available from 2 liters ( lab models) up to 150 liters with/without cooling/heating jackets

- Suitable for kneading dough, battery mixutre,icecream mixer,etc

Plodder Machine

We manufature all types of plodder, Named as pldders for dhoop industries, plodders for soap industries, plodders for food industries

Plodder is available with scre diameter 50 mm upto 125 mm suitable for dhoop manufaturing , chemical compound mixing and kneading , soap and detergent manufacturing applications( with vacuum -double extruder)

Ribbon Mixer

Ribbon mixer widely used for mixing dry powder with variey of viscocity.It is suitable for manufacturing food products like ice cream powder, talcom powder compound, and many more chemical compositions

The ribbon mixer is available with folowing capacities

- 50,100,200,300,500 lit

- simple ribbon mixer

- double ribbon mixer

- Twisted double ribbon mixer

- With without heating,vaccume jacket

Vibro Sifter

Vibro sifters/separators are widely used for separating two types of materials

It runs on single motor, can be single Decker , double Decker or as per specification

Applications:

Pharmaceutical, Plastic, Chemical

- Sizes is available 30", 36", 42" dia

- Standerd or Gmp model

- Three phase motor operated

- Specially designed springs

Pelletizers

Available models:- 80 kg/hour , 120 kg /hour, 250 kg/hour, 350 kg/hour

Blades :- full WPS for up to 150 kg/hour output and solid cutter for production up to 350 kg/hr

Machine is powder coated and zinc plated

Blades are replaced easily by special design of the machine

One gear is made of high quality nylon material for zero noise production

P. V. C. Or Pet Bottle Flame Treatment Machine

In this machine each plastic bottle is rotated for 2 seconds in front of flame/corona treator. This machine is widely used in bottle printing industries, prior to painting on it.This flame treatment machine can be used with corona treator /gas burner heating in place of corona treater attachments

General description:-

- speed :- 25-45 bottle /min

- each time the bottle stops at the flame area and rotates for 1-2 seconds before the next bottle comes in contact with the flame

- No of operators reqired :- 1

- Electricals:- AC three pase 1/2 HP

- optional variable AC drive if required

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.