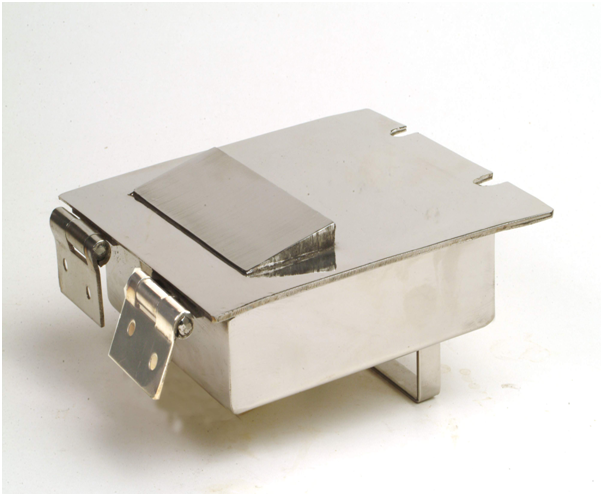

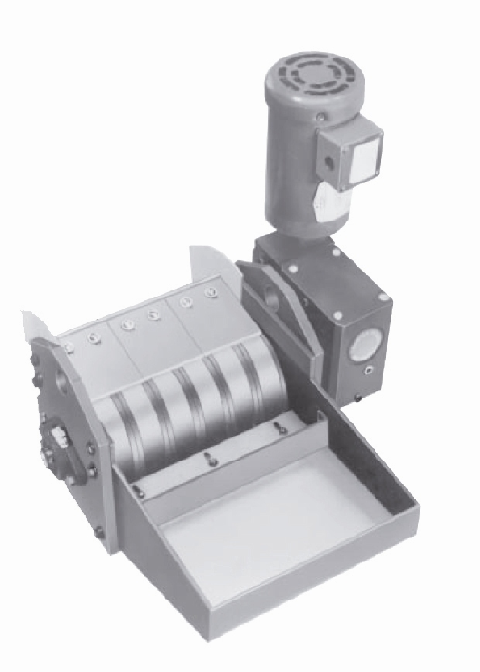

Drawer Type Magnetic Separator

Application

Mining industries

Pharmaceuticals industries

Food processing industries

Industries dealing with powdery substance

Cement, gypsum and other types of small scale industries.

Features

Stainless steel construction

Pre-engineered for fast field installations

Transition for round, square or rectangular spouting.

Self cleaning models available.

Customized sizes available as per customer's requirement.