PARSHVA ENTERPRISE

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PARSHVA ENTERPRISE

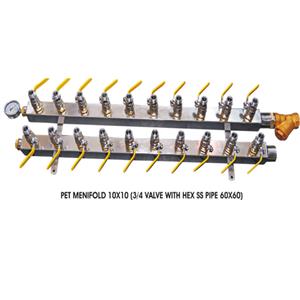

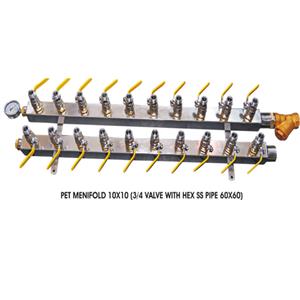

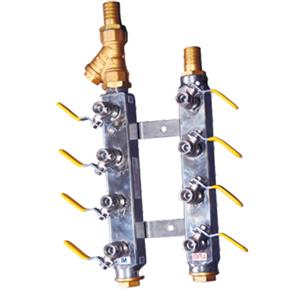

S.S. Water Manifold

Stainless steel manifolds are typically made from 304 square tubing. Pipe fittings for supply, return and distribution ports are welded to the tube. SS manifolds are often specified for highly corrosive cooling water applications. Manifolds are equipped with Brass Hose nipple, pre-drilled mounting holes and screws for ease in pairing and installation.

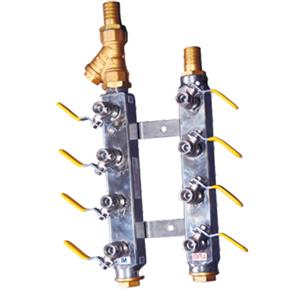

M.S. Water Manifold

Mild steel manifolds are typically fabricated from MS square tubing. Pipe fittings for supply, return and distribution ports are welded to the tube. MS manifolds are Powder coated with PU Paint specified for highly corrosive cooling water applications. Manifolds are equipped with Brass Hose nipple, pre-drilled mounting holes and screws for ease in pairing and installation.

Features and Benefits of both type manifolds

1. Various port sizes available.

2. Brass Y Strainer attached.

3. Pre-drilled mounting holes.

4. Single or parallel manifold.

5. Pressure gauge attachments (optional).

6. Leakage proof.

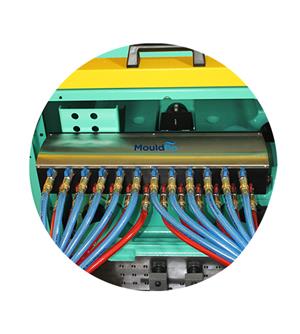

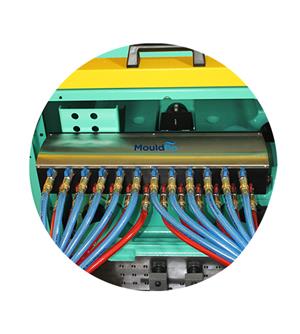

Flow Monitoring System

The Mouldflo system will digitally monitor all of the flow circuit within the mould recording data, both flow and temperature, for every circuit. Often overlooked by many moulders, the efficiency of the mould cooling circuit(s) are critical to stable process and the manufacturer of high quality, dimensionally stable parts.

Mouldflo can protect your mould and improve quality by quickly identifying cooling problems and alerting the user to various common cooling circuit problems, such as;

- No water flow from the mould heater

- Blocked waterways

- Scale/ rust build up

- Incorrect piping

Injection moulders currently use a range of methods for distributing and controlling the water flow around the cooling circuit. Traditionally the most common method has been with water flow regulators. Although cost effective flow regulators suffer from a number of inherent problems:

- Bulky / delicate – have to be mounted away from the mould

- Long pipe runs – reduced flow

- Flow restrictions

- Broken sight glasses

- Do not give a true reading flow

- Sight glasses unreadable due to oxidation

- High levels of maintenance

Oil Cleaning Machine

In order to operate hydraulic systems without failure, hydraulic systems are equipped with precise high-tech components. Sludge, resin & dirt in the oil cause friction, wear and malfunction of the hydraulic systems. More than 80% of hydraulic failure s are caused by impurities in the oil.

The mechanically oil cleaner removes sludge & dirt particles from hydraulic oil and other mineral oil which is as clean as with NAS value 8. Malfunction of hydraulic oil is extended. The cleaned hydraulic oil is much cleaner than new oil.

Features and Benefits

1. Fast return of investment.

2. Precise operation of your hydraulic system.

3. Improved process reliability.

4. Less production cost.

5. Improved availability of your machine.

6. Less cost for maintenance, repairing and oil change.

7. Up to 70% less downtime.

8. Up to 95% less consumption of hydraulic oil.

Hopper Magnet

Our Hopper Magnets provide a properly configured, high-density magnetic field to trap and hold ferrous fines, fragments, and small metal objects. Stainless steel tubing and frames are welded into strong, integral units. They can be installed – or simply laid – inside hoppers, housings, and bins – and easily removed for cleaning. Grates are built for low-abrasion applications and should measure at least twice the size of your outlet opening, so as not to restrict product flow.

Mould Clamp

Mould Clamp is designed specially for low height applications only such as clamping of moulds on plastic injection moulding machines & pressure die casting machines. The compact front portion of the clamp enables it to penetrate into the limited clamping area of the mould and clamp it. The positioning of forged swival washer on required curved groove enables the operator to set the center distance between the clamping portion and the clamping bolt as per the nearest tapped hole available on platen (where there are no T-slots). No supports are required at the rear of the clamp as the rear portion rests on the platen and front holds the mould. Flanged nut is tightened on the swival washer which takes care of the positioning of clamp body. These clamps are equally useful on pressure die casting machines, hydraulic presses & power presses where low height clamping is done. Clamps are supplied complete with swival washer, flanged nut & clamping stud or T-Bolt as shown in tables below.

P.U. Hose Pipe

Product Specification

We have PU Hose also in wall thickness of 1.2mm & 2.5mm. This Heavy Duty PU Hose mainly use to convey some material like powder, granules some chemicals etc. Inner surface for these PU Hoses is smooth so better conveying of materials. This product is also Made in Germany.

Temperature

-40° C to + 90° C ( Short term + 125° C )

Available Sizes

38mm to 200mm

Made in Germany

Silicon Hose Pipe

Silicon Hoses is made of Silicone coated Double Layer glass-fiber fabric with inner hidden steel spring spiral and outer glass fiber cord. They are universally used for high-temperature but low-pressure applications. Good flow characteristics due to additional interior lining. They can be laid in closest areas (small bending radius), are kink-proof, very flexible and light weight. We provide Double Layer Silicon Hose.

S.S. Breaded Hose Pipe

"Stainless steel annular corrugated metallic flexible hoses are manufacturing in austantic steel ANSI 321, 316, 316L & 304 grades conforming to BS 6501, Part-1 : 2004 / ISO 10380 : 2003. The annular corrugated metallic hose body provided the flexibility and pressure tight core of the assembly. We supply highly flexible close –pitch hoses for special applications. Stainless steel annular corrugated metallic flexible hose are offered from Size : 1/4"(DN 6) to 12"(DN 300). When pressure is applied, unbraided hose tends to elongate axially; to restrain this, an external layer of SS wire braid is provided. The braid also makes the assembly pressure compatible. Sometimes two or even three layers of braiding are provided for high pressure applications. The braiding is highly flexible and follows the movement of the hose. The braid is normally manufactured in SS 304 wire. However SS 316 and 321 braids can also be manufactured. We also supply wire braid in different configurations as per customer specifications."

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.