PAR TECHNO HEAT PVT. LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PAR TECHNO HEAT PVT. LTD.

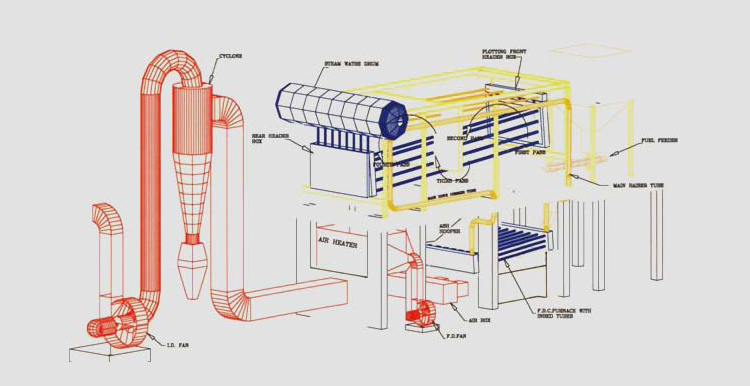

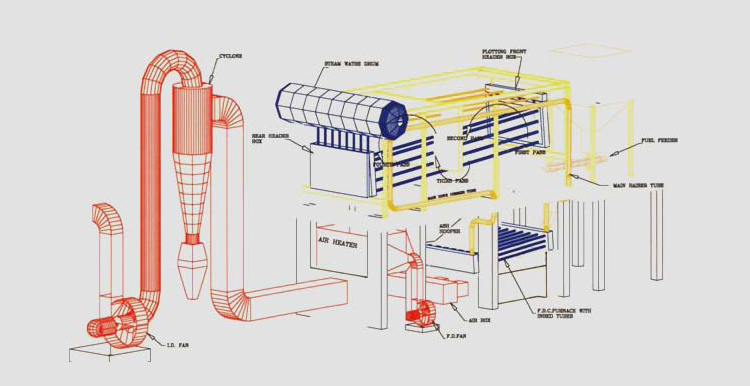

Four Pass Single Drum Water Tube Fbc Steam Boiler

Fuel: Coal Dust, Lignite Dust, Saw Dust, Bio-Mass, Wood Chips, Agro-Waste, Rice Husk, GN Shell, DOC , Mustered Stalk, Cotton Stalk, Coffee Waste, Spice Waste Dust, Empty Palm Fruit Bunches (EPFB), Spent Bleach Earth (SBE) , Baggase

Steam Generation Capacity: 0.5 TPH up to 25 TPH

Working Pressure Upto 30 Kg/Sq.Cm.

Features

4 Pass design, ensures better heat utilisation & ultimate thermal efficiency.

Fluidised Bed Combustion furnace ensures very high combustion efficiency, up to 95% even with fuel, having very high ash & fine contents and having very low calorific value.

Straight tube in generating bank enables manual cleaning & easy inspection.

The rectangular headers are of welded type box headers with individual opening against each tube at both ends of generating bank. Hence, for cleaning & maintenance of any single tube only single door cap, weighing just 1.5 kg has to be opened.

Larger tube diameter in generating bank, i.e. 76.2 mm OD, enables easy manual cleaning.

Intermediate tube supports in the generating bank, which prevents tube sagging contributes to higher boiler life.

Wide gap in tube spacing i e. 160 mm pitch, prevents inter tube space plugging by soot deposition, which permits trouble free operation without external cleaning as clogging of tube space with soot does not take place.

Free floating front header takes care of longitudinal thermal expansion. Hence, thermal stresses are not developed during heating. This design enhances boiler life too.

Man hole opening at both sides of the drum for easier access to drum internals.

Larger diameter drum coupled with drum internal steam separators ensures dry steam even at full main steam valve opening.

Moderately larger furnace area and higher free board height, above grate, makes the boiler capable to burn low grade, high volatill3 & ash contained solid fuel efficiently without reducing rated steam generating capacity.

No inventory of spares, since nothing special is employed which is necessary to be procured urgently from us or which is not available in the free market.

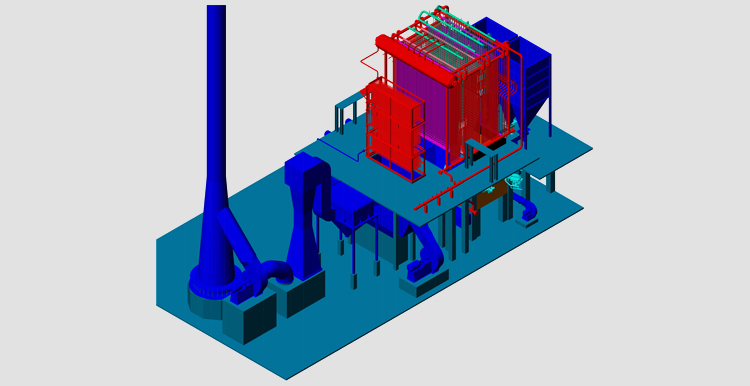

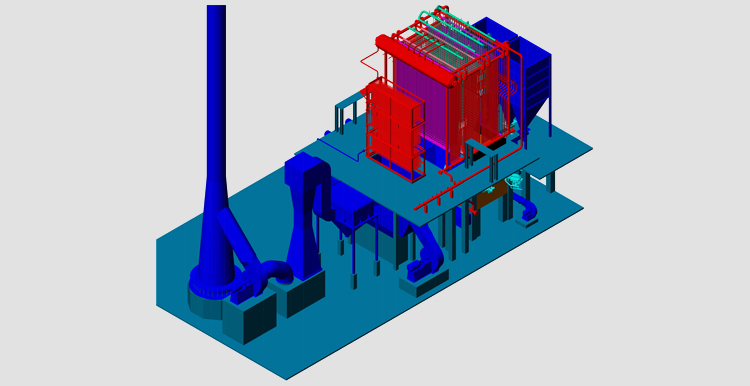

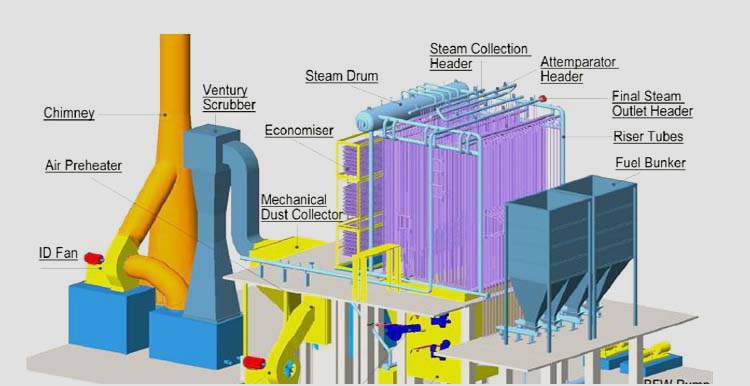

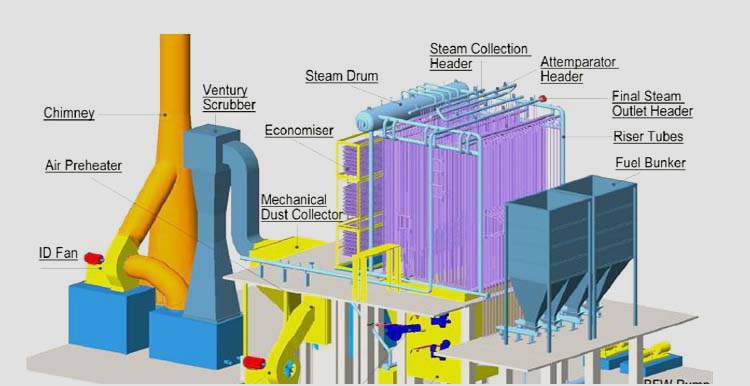

Single Drum Water Tube In Corner Pipes And Membrane Wall Configuration Fbc Steam Boiler

Fuel: Coal Dust, Lignite Dust, Saw Dust, Bio-Mass, Wood Chips, Agro-Waste, Rice Husk, GN Shell, DOC , Mustered Stalk, Cotton Stalk, Coffee Waste, Spice Waste Dust, Empty Palm Fruit Bunches (EPFB), Spent Bleach Earth (SBE) , Baggase

Steam Generation Capacity: 3 TPH to 60 TPH

Working Pressure 33 Kg/Sqm.C. to 69 Kg/Sq.Cm.

Super Heater Steam Temp Up to 490° C

Features

Single Drum Corner pipes design, which is the only choice for a very high pressure and temperature Boiler, is being offered even for medium pressure Boiler which is highly acclaimed all over ward for it's reliability of performance & sturdiness.

The Drum does not form an integral part of the water - Steam circulation circuit, as all the water and Steam do not need to flow through the drum.

By arrangement of Top Headers, the re-circulated water does not flow to the drum, but re-circulation is thro' Top & Bottom Headers. This ensures better steam quality from the drum, as steam separation starts from Headers.

Bi-Drum Design, the Bank Tubes are expanded in to two Drums. The expanded joints in high pressure Boiler are a constant source of trouble. Where as in the Single Drum Designs, the Bank Tubes are in Panels and welded. There are easily approachable. Hence Tube replacement and maintenance in future is very easy.

Single Drum Design, the Drum is Outside the Flue gas path and there are no Tube Holes expect for opening for 4 Headers. These openings are also fully compensated which results in much thinner shell plate thickness and minimum thermal stress.

Water Wall 2.1/2" size Tubes/Pipes are spaced 1" apart. This provides larger volume of Water in our Furnace Walls and contributes to a faster load response. In addition, our uniquely designed Drum Internals can handle varying loads without circulation disruptions on carry over.

Furnace Wall Water Cooling includes side walls & Bed Coil, eliminating Refractory and its attendant Maintenance.

Gas tight setting Membrane provides the gas tight setting, which eliminates dew - point sulfur corrosion and outages caused by gas leaks. Par's Membrane Panels use larger Dia Tubes and Small Membrane spacing which provides the best combination of heat transfer efficiency & Maintenance accessibility.

Drum Internals provides high Steam purity.

Direct in Bed Feeding System: Firing is neither Under Bed, nor Over Bed but directly in the Bed. This arrangement make it possible to use wide range of Solid Fuel.

Pressurised Economiser & Air Pre Heater is provided for better waste Heat Recovery and to increase the overall Thermal efficiency of the Boiler.

IBR Economiser as well as Air Pre Heater both are incorporated to minimise dry Flue Gas losses and maximise the waste Heat Recovery.

Bi Drum Water Tube Fbc Steam Boiler

Steam Generation Capacity: 6 TPH to 50 TPH

Working Pressure 69 Kg/cm2

Super Heater Steam Temp 490° C

Features

Bi-Drum Water Tube Steam Boiler design, which is highly acclaimed ail over ward for it's reliability of performance & sturdiness.

Water Wall 2½" size Tubes are spaced 1" apart. This provides larger volume of Water in our Furnace Walls and contributes to a faster load response. In addition, our uniquely designed Drum internals can handle varying loads without circulation disruptions on carry over.

Furnace Wall Water Cooling includes side walls & roof, eliminating Refractory and its attendant Maintenance.

Gas tight setting Membrane provides the gas tight setting, which eliminates dew - point sulfur corrosion and outages caused by gas, leak Par's Membrane Panels use larger diameter Tubes and Small Membrane spacing which provides the best combination of heat Veneer efficiency & Maintenance accessibility.

Drum Internals provides high Steam purity and ensure positive circulation.

Soot Blowers are properly located for effective convection Bank cleaning.

Furnace inBed Cooling Coil: In Bed Tube material is BS:3059 Gr.360 Seamless, utilises higher dia, i.e. 63.5mm OD Tubes for better Thermal Storage & response.

Fluidising Air Nozzles are made up to CI with Chrome & Nickel, which provide very good heat & abrasive resistance.

Direct in Bed Feeding System: Firing is neither Under Bed, nor Over Bed but directly in the Bed. This arrangement make it possible to use wide range of Solid Fuel.

Larger diameter Steam Drum with effective Drum Internals ensure dry steam at Drum outlet.

Pressurised Economiser & Air Pre Heater are provided for better Waste Heat Recovery and to increase the overall Thermal Efficiency of the Boiler, (Pressurised Economiser is supplied only incase of high pressure Steam Boiler)

Three Pass Horizontal Smoke Cum Water Tube Combi Boiler With Membrane Wall Fbc Furnace

Steam Generation Capacity: 1 TPH to 15 TPH

Working Pressure Upto 17.5 Kg/Sq.Cm.

Advantages Of Fluidised Bed Combustion Boilers:

High Efficiency - FBC boilers can burn fuel with a combustion efficiency of over 95% irrespective of ash content. FBC boilers can operate with overall Thermal efficiency of 82% (plus or minus 2%).

Compact in Boiler Size - High heat transfer rate over a small heat transfer area immersed in the bed result in overall size reduction of the boiler.

Fuel Flexibility - FBC boilers can be operated efficiently with a variety of fuels. Even fuels like Coal , Husk , agro waste can be burnt efficiently. These can be fed either independently or in combination with coal into the same furnace.

Ability to Burn Low Grade Fuel - FBC boilers would give the rated output even with inferior quality fuel. The boilers can fire coals with ash content as high as 60% and having calorific value as low as 2,500 kcal/kg. Even carbon content of only 1% by weight can sustain the fluidised bed combustion.

Ability to Burn Fines - Coal containing fines below 6 mm can be burnt efficiently in FBC boiler, which is a very difficult to achieve in conventional firing system.

Low Corrosion and Erosion - The corrosion and erosion effects are less due to lower combustion temperature, softness of ash and low particle velocity (of the order of 1 m/sec).

Easier Ash Removal - No Clinker Formation- Since the temperature of the furnace is in the range of 750 - 900° C in FBC boilers, even coal of low ash fusion temperature can be burnt without clinker formation. Ash removal is easier as the ash flows like liquid from the combustion chamber. Hence less manpower is required for ash handling.

Less Excess Air - Higher CO2 in Flue Gas - The CO2 in the flue gases will be of the order of 14 - 15% at full load. Hence, the FBC boiler can operate at low excess air - only 20 - 25%.

Simple Operation, Quick Start-Up - High turbulence of the bed facilitates quick start up and shut own. Full automation of start up and operation using reliable equipm

Fast Response to Load Fluctuations - Inherent high thermal storage characteristics can easily absorb fluctuation in fuel feed rates. Response to changing load is comparable to that of oil fired boilers.

No Slagging in the Furnace-No Soot Blowing - In FBC boilers, volatilisation of alkali components in ash does not take place and the ash is non sticky. This means that there is no slagging or soot blowing.

Provisions of Automatic Coal and Ash Handling System - Automatic systems for coal and ash handling can be incorporated, making the plant easy to operate comparable to oil or gas fired installation.

High Reliability - The absence of moving parts in the combustion zone results in a high degree of reliability and low maintenance costs.

Reduced Maintenance - Routine overhauls are infrequent and high efficiency is maintained for long periods.

Quick Responses to Changing Demand - A fluidized bed combustor can respond to changing heat demands more easily than stoker fired systems. This makes it very suitable for applications such as thermal fluid heaters, which require rapid responses.

High Efficiency of Power Generation - By operating the fluidized bed Boiler at elevated pressure, it can be used to generate power with a back pressure steam turbine. And the steam from the turbine exhaust can be utilized for process while generating the power.

Multi Solid Fuel Fired Small Industrial Boiler

Steam Generation Capacity: 100 Kgs/hour to 700 Kgs/hour

Working Pressure Up to 7 Kg/Sq.Cm.

Features

It is designed & manufactured under IBR inspections and dully approved by IBR. It means that the Boiler is guaranteed by a third party for I quality, reliability of performance and its ultimate safety.

Even if boiler is IBR approved there is no need to employ 2nd class toile attendant. Only matriculate fellow is eligible to run the boiler.

The boiler is required to be offered for open & hydraulic test inspection once in 2 years, to Boiler Inspector..

Boiler is a combination of Smoke Tube & Water Tube technology.

Membranes Water wall external furnace makes use of direct radian o heat from furnace.

Being an external membranes wall furnace, boiler is very much suitably for fuel like Lignite / Agro waste / Wood etc. With an option of FBC furnace, cheaper fuel like Saw Dust can be used, which is other impossible to be used in hand fired boiler.

High thermal efficiency of 75 % ±2 % can be obtained, with hand firing With an option of FBC system with a Micro Processor Based fuel feed - & combustion air pre heater, efficiency unto 87 % +1-2 % can obtained.

Though approved by IBR, one can enjoy all freedom of a Non IBR Boil-and still meets the mandatory requirements, pertaining to safety.

Pay back period of the new boiler plant, against an Oil fired boiler, is less than 6 Months.,

Multi Solid Fuel Fired Four Pass Vertical Thermic Fluid Heating System

Fuel Coal, Lignite, Rice Husk, GN Shell Husk, Saw Dust (Wood Chips), DOC

Capacity: 4 Lacs K-cal/hour to 30 Lacs K-cal/hour

Maximum Temp 300° C

Other Special Design up to 360° C Temp Available

Oil Fired Thermo packs are also offered.

Features

4 Pass Design ensures better heat utilisation & Ash separation.

With Fluidised Bed Combustion furnace design, very high Thermal Efficiency of 80%+-2% can be achieved.

Automatic Mechanised screw fuel feeding makes fuel feeding OFF & ON when set temperature is achieved & reduced, respectively.

Micro Processor Based V/F fuel feed drive is used to adjust the rate of fuel feeding as per Plant load requirement.

Most of the Solid Fuels, including Crushed Coal / Lignite / Agro waste / DOC / Saw Dust can be used in this system.

Large size Air Pre-Heater / Water ,Pre-Heater, reduces dry flue gas losses and improves the Waste Heat Recovery and increases combustion Air Temperature.

Radiant Coils installed directly on FBC Furnace makes maximum utilisation of Furnace radiation heat.

Mechanical Dust Collector arrests the fly Ash from Flue gas, before exhausting to Chimney.

Ash collection pit is provided below convective coils.

Air Pollution Control Equipment

Electrostatic Precipitator (ESP)

Electrostatic precipitator (ESP) is a widely used device in so many different domains to remove the pollutant particulates, especially in industrial plants.

And as it name implies it uses the electrostatic fundamentals (corona discharge) for trapping and removing industrial emission like boiler exhaust. That’s why it is named as ESP.

Physical components of Electrostatic Precipitator

Collecting and discharge electrodes

Collecting electrodes

plate type and tube type.

Occasionally made of stainless or an alloy steel.

Generally 0.05 to 0.2 cm in thick.

Discharge electrodes

plate type and wire type

made of high carbon steel but also can be constructed of S.S. copper, titanium alloy & aluminum

Spikes having a corona material.

Comparison of Bag-Filter and ESP

Comparison based on parameters

For low emission less than 30mg/nm3 go for a bag-filter

For high temperature more than 260°c go for ESP

If moisture content in flue gas is more than 20% go for bag-filter

If dust resistivity is very high or very low which will be difficult to charge in ESP go for a bag-filter.

In power industry normally we find ESP but in cement industry bag-filter is generally used due to dedusting action.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

And Boiler 53698.jpg)

And Boiler 53698.jpg)

For Ceramic Spray Dryer And Kilns 53701.jpg)

53703.jpg)