PAR TECHNO HEAT PVT. LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PAR TECHNO HEAT PVT. LTD.

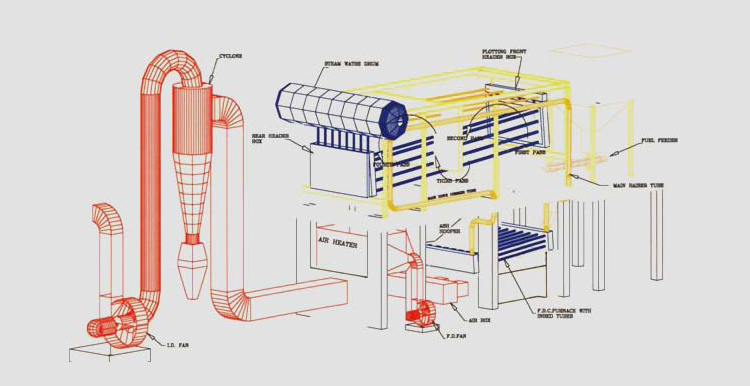

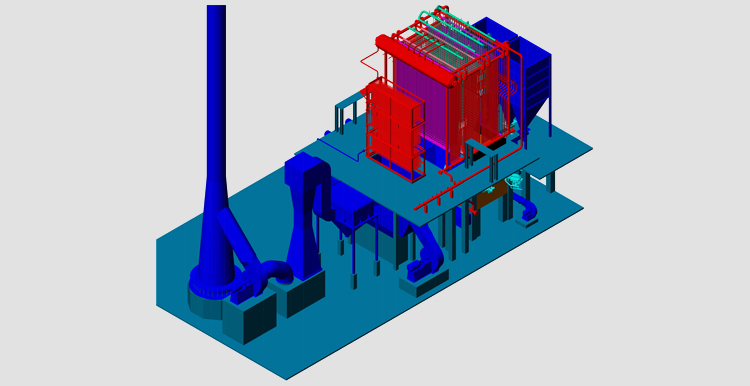

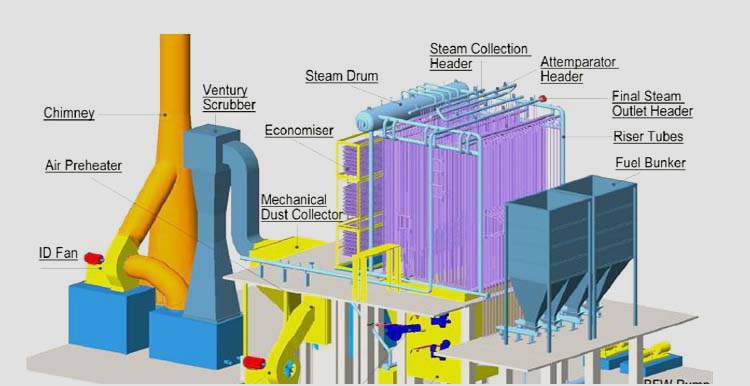

Multi Solid Fuel Fired Small Industrial Boiler

Steam Generation Capacity: 100 Kgs/hour to 700 Kgs/hour

Working Pressure Up to 7 Kg/Sq.Cm.

Features

It is designed & manufactured under IBR inspections and dully approved by IBR. It means that the Boiler is guaranteed by a third party for I quality, reliability of performance and its ultimate safety.

Even if boiler is IBR approved there is no need to employ 2nd class toile attendant. Only matriculate fellow is eligible to run the boiler.

The boiler is required to be offered for open & hydraulic test inspection once in 2 years, to Boiler Inspector..

Boiler is a combination of Smoke Tube & Water Tube technology.

Membranes Water wall external furnace makes use of direct radian o heat from furnace.

Being an external membranes wall furnace, boiler is very much suitably for fuel like Lignite / Agro waste / Wood etc. With an option of FBC furnace, cheaper fuel like Saw Dust can be used, which is other impossible to be used in hand fired boiler.

High thermal efficiency of 75 % ±2 % can be obtained, with hand firing With an option of FBC system with a Micro Processor Based fuel feed - & combustion air pre heater, efficiency unto 87 % +1-2 % can obtained.

Though approved by IBR, one can enjoy all freedom of a Non IBR Boil-and still meets the mandatory requirements, pertaining to safety.

Pay back period of the new boiler plant, against an Oil fired boiler, is less than 6 Months.,

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

And Boiler 53698.jpg)