PAR TECHNO HEAT PVT. LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PAR TECHNO HEAT PVT. LTD.

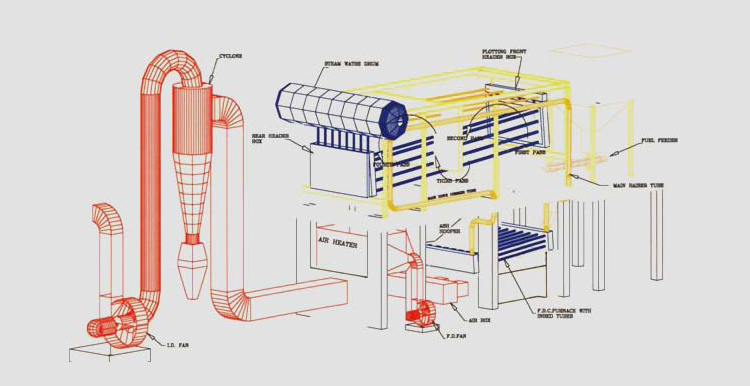

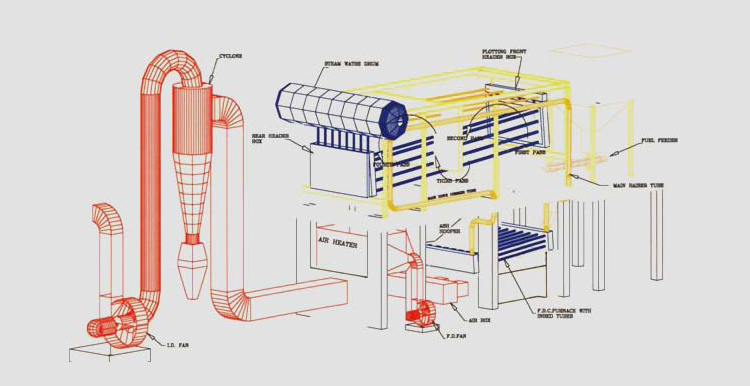

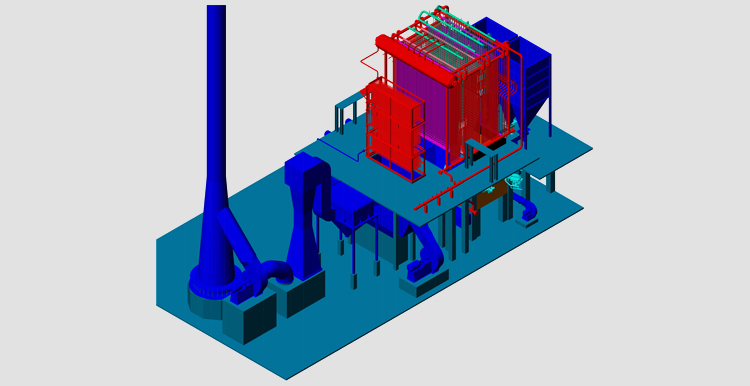

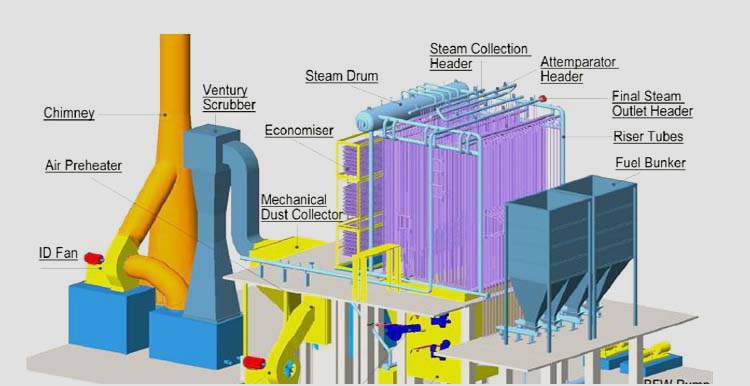

Four Pass Single Drum Water Tube Fbc Steam Boiler

Fuel: Coal Dust, Lignite Dust, Saw Dust, Bio-Mass, Wood Chips, Agro-Waste, Rice Husk, GN Shell, DOC , Mustered Stalk, Cotton Stalk, Coffee Waste, Spice Waste Dust, Empty Palm Fruit Bunches (EPFB), Spent Bleach Earth (SBE) , Baggase

Steam Generation Capacity: 0.5 TPH up to 25 TPH

Working Pressure Upto 30 Kg/Sq.Cm.

Features

4 Pass design, ensures better heat utilisation & ultimate thermal efficiency.

Fluidised Bed Combustion furnace ensures very high combustion efficiency, up to 95% even with fuel, having very high ash & fine contents and having very low calorific value.

Straight tube in generating bank enables manual cleaning & easy inspection.

The rectangular headers are of welded type box headers with individual opening against each tube at both ends of generating bank. Hence, for cleaning & maintenance of any single tube only single door cap, weighing just 1.5 kg has to be opened.

Larger tube diameter in generating bank, i.e. 76.2 mm OD, enables easy manual cleaning.

Intermediate tube supports in the generating bank, which prevents tube sagging contributes to higher boiler life.

Wide gap in tube spacing i e. 160 mm pitch, prevents inter tube space plugging by soot deposition, which permits trouble free operation without external cleaning as clogging of tube space with soot does not take place.

Free floating front header takes care of longitudinal thermal expansion. Hence, thermal stresses are not developed during heating. This design enhances boiler life too.

Man hole opening at both sides of the drum for easier access to drum internals.

Larger diameter drum coupled with drum internal steam separators ensures dry steam even at full main steam valve opening.

Moderately larger furnace area and higher free board height, above grate, makes the boiler capable to burn low grade, high volatill3 & ash contained solid fuel efficiently without reducing rated steam generating capacity.

No inventory of spares, since nothing special is employed which is necessary to be procured urgently from us or which is not available in the free market.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

And Boiler 53698.jpg)