Pultruded F.R.P Cooling Towers

Paltech Pultruded FRP Cooling Towers are available with single cell capacity upto 5000 M3/Hr & Multi cell capacities upto any size in counter flow design with film fill & splash fill design.

Paltech, Pultruded FRP Cooling Towers which are not only efficient but also of ultimate quality, reliability and longevity. They are best suited for sea water application, as a replacement for old large Wooden Cooling Towers and as a new Cooling Tower instead of RCC or Wooden Cooling Towers.

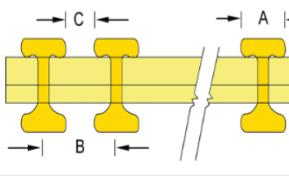

STRUCTURE is made up of Pultruded Fiberglass material.

HARDWARE Hot dip galvanized are used to withstand corrosion. Stainless Steel hardware is available at extra cost.

CASING is made up of Pultruded FRP/Corrugated FRP Sheets of adequate thickness.

FAN DECK is made up of robust & Strong Pultruded FRP Panels/Sheets.

FRP FANS are of proven design provided by Indian Institute of Technology.

FAN CYLINDER is made up of tough & durable FRP/GRP material.