PACKSOL INDUSTRIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PACKSOL INDUSTRIES

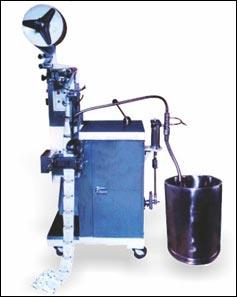

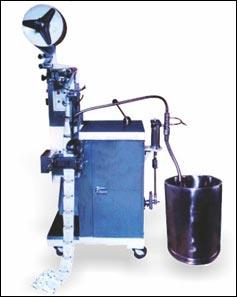

Machine For Packing Liquid

Application:

The machine operates on the principle of Volumetric syringe filling system with a provision of volume adjustment. This machine can pack liquid items such as Shampoo, 2T oil, Syrup, Hair Oil, Soft Drink, Mineral water, etc.

Sealing Type :

3 Side Sealing / 4 Side Sealing

Packing Size :

50mm - 150 mm (film length)

50mm - 200mm (film width)

(Enlarge type can be made upon order)

Packing Range :

5ml - 25ml, 40ml - 100ml

(Depending on specific gravity of material to be packed)

Speed :

28-30 pouches /min.

(Depending on flow rate and volume of the product.) Convenient package size & packing speed are adjustable.

Packing Material :

All heat sealable laminate PET / POLY, PET / FOIL / POLYMET, PET /POLY/ CPP / OPP etc.

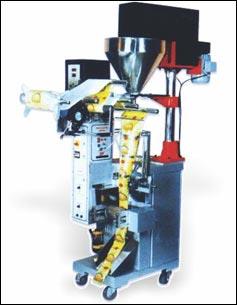

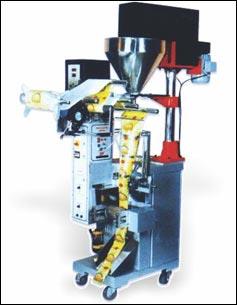

Machine With Auger System

Application:

The Auger Base Form-Fill-Seal Machine operates on the principle of Positive Displacement Screw under constant head. Auger Filler Machine is a versatile powder filling machine for packing non free flowing powder like Pharmaceutical Powder, Chemical Powder, Talcum Powder, Ground Spices, Ground Coffee, Colour, Milk Powder, Baby Foods Powder, Custard Powder, Henna Powder etc.

Sealing Type :

3 side sealing / 4 side sealing / Centre sealing.

Packing Size :

50 mm - 150mm (film length)

30mm – 220mm (film width)

( Enlarge type can be made upon order )

Packing Range :

From 10gms, 25gms, 50gms to 1OOgms (Depending on specific gravity of material to be packed )

Speed :

25 - 28 pouches / min.

(Depending on flow rate and volume of the product)

Packing Material :

Any heat sealable laminate or Alu. Foil based material

Machine For Packing Edible Oil

Application:

Automatic Liquid Packing Machine is designed for a special purpose of large volume pack sealing type liquid soft packages. It can use composite films as its packaging materials and automatically finish bag making, filling, sealing, cutting and date printing etc. The packaging volume can be adjusted within the allowable range. The sealing system adopts temperature regulation heating to guarantee a stable and reliable sealing quality. Its horizontal seal system can finish the sealing and hot cutting at one go. A pattern calibration photoelectric control device will be put into the process of package to ensure that the patterns will be complete and beautiful. Production date will be printed by use of ribbon hot code printing system so as to keep a clear print and last for a long time. This Machine can pack Mineral Water, Wines, Juice, Milk, Liquid Ghee, Soya Sauce, Neera, Lube Oils, Paints etc.

Machine With Adjustable Dish

Application:

This machine is suitable for packing any free flowing Powder, Granules, Spices, Mehendi, Churn, Pharmaceutical Powder, Agricultural Powder, Ayurvedic Powder, Tea, Detergents, Chemicals, Kirana Items etc.

Sealing Type :

Centre sealing

Packing Size :

100mm - 280mm (film length)

200mm - 400mm (film width)

(Enlarged type can be made upon order)

Packing Range :

50gms, lOOgms, 250gms & 500gms

(Depending on specific gravity of material to be packed)

Speed :

25 - 28 pouches / min.

(Depending on flow rate & volume of the product).

Packing Material :

All heat sealable laminate PET / POLY, PET / FOIL / POLY MET, PET / POLY / CPP / OPP etc.

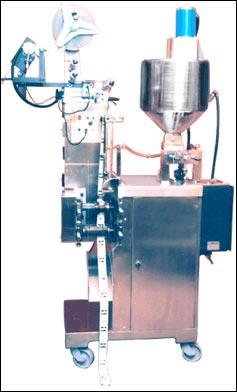

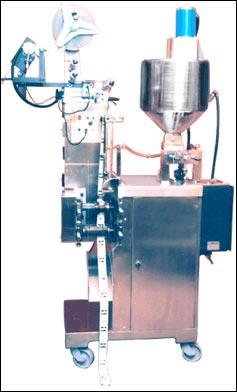

Machine For Packing Paste

Application:

The Machine consist of a hopper mounted volumetric pump dosing with rotary valve system & a hot water jacketed with provision for stirring by geared motor. This machine can pack Jelly, Chocoliquid, Cream, Sauce, Toothpaste, Ketchup etc.

Sealing Type :

3 side sealing / 4 side sealing

Packing Size :

60mm - 160mm (film length)

40mm - 160mm (film width)

(Enlarge type can be made upon order)

Packing Range :

55gms - 35gms

(Depending on specific gravity of material to be packed)

Speed :

25 - 28 pouches / min.

(Depending on flow rate & volume of the product).

Packing Material :

All heat sealable laminate PET/POLY, PET/FOIL/POLY MET, PET/POLY/CPP/OPP etc.

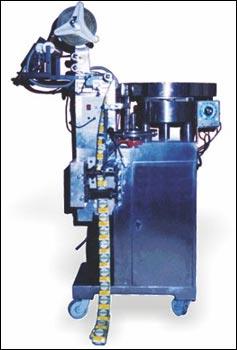

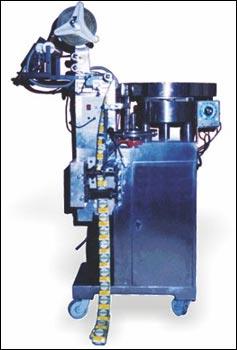

Machine For Packing Tablet

Application:

The Machine operates on the principle filling of volumetric dish counting system. It is suitable for automatic packaging of medicine & food stuff products such as Sugar Coat Tablet, Medicine Tablet, Chocolate Pill, Round Sugar Ball etc.

Sealing Type :

3 side sealing / 4 side sealing / centre sealing

Packing Size :

100mm - 280mm (film length)

200mm - 400mm (film width)

(Enlarge type can be made upon order)

Packing Range :

55gms - 35gms

(Depending on specific gravity of material to be packed)

Speed :

20 - 22 pouches / min.

(Depending on flow rate & volume of the product)

Packing Material :

All heat sealable laminate PET/POLY, PET/FOIL/POLY MET, PET/POLY/CPP/OPP etc.

Machine With Vibrator And Conveyor System

Application:

The vibrator / conveyor system is mounted on F.F.S.Machine for packing any shape & size of solid pieces like Syringes, Rings, Automobile Spare Parts, Hardware Items, Eyedroppers, Dabbi etc.

Sealing Type :

3 side sealing / 4 side sealing / centre sealing

Packing Size :

50mm - 140mm (film length)

30mm - 100mm (film width)

(Enlarged type can be made upon order)

Packing Range :

Depending on specific gravity of material to be packed

Speed :

20 - 22 pouches / min.

(Depending on flow rate & volume of the product)

Packing Material :

All heat sealable laminate PET/POLY, PET/FOIL/POLY MET, PET/POLY/CPP/OPP etc.

Fully Automatic Pneumatic Collar Type Machine

Application:

It consist of a volumetric dish fitted on the top of the machine. A film roll of suitable width has to be mounted at the back of the machine. Then the film goes into the unwinding assembly & then enters into the forming collar & forms into a tube. The vertical sealer seals the front of the tube. Then the material is filled & the bottom seal is made. The cutter then automatically separates the pouch. The machine is suitable for packing Tea, Detergent Powder, Kirana Items etc.

Sealing Type :

Centre Sealing

Roll width :

Max. 425mm & Min. 120mm

Pouch dimension :

65mm - 300mm (film length)

50mm - 200mm (film width)

(Enlarged type can be made upon order)

Packing Range :

50gms, lOOgms, 250gms, 500gms & lkg.

Speed :

28 - 30 pouches / min.

(Depending on flow rate & volume of the product)

Packing Material :

All heat sealable laminate PET/POLY, PET/FOIL/POLY MET, PET/POLY/CPP/OPP etc.

Horizontal Flow Wrap Packing Machine

Application:

To wrap any kind of solid commodities such as biscuit, soaps, chocolate, cakes, instant noodles & any other rectangular, square, , round or irregular shaped product.

Sealing Type :

Pillow type sealing / centre sealing

Packing Size :

40mm - 300mm (film length)

20mm - 125mm (film width)

5mm - 56mm (film height)

(Enlarged type can be made upon order)

Packing Range :

Depending on specific gravity of material to be packed

Speed :

70 - 130 pouches / min.

(Depending on flow rate & volume of the product)

Packing Material :

All heat sealable laminate PET/POLY, PET/FOIL/POLY MET, PET/POLY/CPP/OPP etc.

Semi Automatic Volumetric Filling Machine Two Head

Semi automatic liquid filling machine for filling free flowing liquid such as Edible Oil, Hair Oil, Lubrication Oil, Shampoo, Juice in container, jar, pouch, tin etc.

Specification :

Filling Range

5ml–50ml, 100ml – 250ml, 250ml – 500ml & 1000ml

Machine Dimension

(L) 600mm x (W) 755mm x (H) 680mm

Power Supply

440volts / 3 Phase ( 4 wire system )

50 cycles / Sec. - 0.5 H.P. Output

Filling Speed

300 to 1500 fills / hour

(Depending on Volume / Viscosity of the Liquid be Filled)

Net Weight

80 Kgs. ( Approx )

Semi Automatic Auger Filler Machine

Semi-Automatic Machine with Auger Filling System operates on the principle of positive displacement Screw operating under constant head it will have a hopper and provided with a lid. The precisely designed Auger displaces the product through funnel into the container held under the funnel. A presettable electronic controller with photoelectric sensor will be provided to control the filling cycle through an enclosed electromagnetic clutch/brake unit. The machine is ideal for filling wide range of non free flowing powder.

Semi Automatic Volumetric Cup Filler System

The machine operates on the principle of volumetric portioning which is achieved by telescopic cups to absorb the batch variation of bulk density. The machine discharges the set quantity of product into the pouch / container held manually under the discharge hopper. The machine is ideal for filling wide range of free flowing powder.

Specification :

Filling Range

25gms – 50gms – 100gms – 250gms – 500gms – 1000gms

Filling Speed

30 – 32 fills per min.

(Depending upon the product & quantity to be filled)

Electricity

1hp., 220V single phase

Machine Dimension

(L) 800mm x (W) 800mm x (H) 1500mm

Net Weight

150kgs.

Foot Operated Heat Sealer For Sealing Filled Pouches

The Foot operated sealing machine has a timer and a buzzer incorporated in it for ease of operation. The thicker the bag, the timer increases for sealing & vice versa. The buzzer informs the operator as to when the sealing is completed. The platform can be titled toward the operator thereby assuring effortless operation in sealing the pouches.

Specification :

Jaw Size

8”, 12”, 16”, 18”, 20”, 24”

Sealing Width

10 – 15mm

Type

Impulse sealing / Line type sealing

Power

230 Volt, Single Phase, 50/60hz power supply

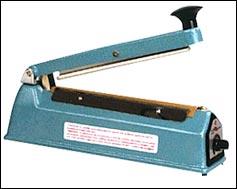

Hand Operated Sealing Machine

It is very suitable for small scale production. It has a timer for sealing different guage & different plastic materials. It has a buzzer for indicating the completion of sealing process. Seals PE, PP, BOPP, HM, Metallised film etc.

Specification :

Sealing size

8”, 12”, 16”, 20”

Type

Impulse sealing

Power

230 Volt, Single Phase, 50/60hz power supply

Automatic Vertical Form Fill Seal Machine For Packing Powder

Application:

This machine is suitable for packing any free flowing Powder, Granules, Spices, Pan Masala, Dhana Dal, Tobacco, Mehendi, Churn, Pharmaceutical ORS Powder, Agricultural Powder, Ayurvedic Powder, Tea, Detergents, Chemicals etc.

Sealing Type :

3 Side Sealing / 4 Side Sealing

Packing Size :

50 mm – 150mm (film length)

30mm – 220mm (film width)

( Enlarge type can be made upon order )

Packing Range :

1gms, 5gms, 10gms, 25gms to 50gms

(Depending on specific gravity of material to be packed)

Speed :

35 – 38 pouches / min

(Depending on flow rate and volume of the product.) Convenient size & packing speed are adjustable.

Adjustment can be made while the machine

is running.)

Packing Material :

All heat sealable laminate PET / POLY, PET / FOIL / POLY MET, PET / POLY / CPP / OPP etc.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.