ORBIT EQUIPMENTS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ORBIT EQUIPMENTS P.LTD.

Pallestisers

Pallet Transfer System

Pallet Transfer Conveyors

Palletiser

Barrel Palletiser

PALLETISER - LOW LEVEL

Automatic low level sweep type palletising system.

Extremely economic and versatile model suitable for medium production rates.

Quick changeover

Program selection set from the control panel supplied.

Very strong main frame with 2 columns, supporting one vertical chain driven trolley. Pack in feed and collation conveyor to present incoming product in the correct position for transfer onto the pallet. Mechanical pusher unit to sweep rows onto loading station. Pallet loading station, complete with guides, mechanical and pneumatic driven. Side opening stainless steel bed to deposit product onto pallet. Anti-fall device for lift trolley. Integral control panel complete with operator push buttons controls. Alphanumeric display with function key board, complete with diagnostic program. Safety guards

10 pallets capacity pallet de stacker unit

Optional Layer pad inserter between layers with adjacent storage

PALLETISER – HIGH LEVEL

When design and floor space are at a premium, the High Level Palletiser is perfectly adapted to do the job. Reaching speeds of up to 60 units per minute (depending on sizes, stacking pattern and configuration), the High Level Palletiser can handle several types of containers, including cases, totes, trays, jugs, pails, bags, etc.

Designed for today’s demanding requirements, the High Level Palletiser with the optional Stack & Wrap feature is the proven solution for your palletising challenges. The Stack & Wrap option consists in an innovative and simplistic design that integrates state-of-the-art technologies. This combination allows for an even smaller footprint and a lower cost.

Completely automatic, no operator required

8-pallet-capacity magazine with an open back design that is easily expandable

Wide range of options available

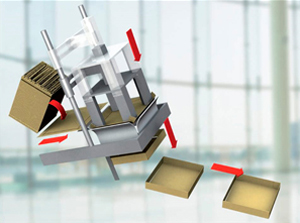

PALLETISER – GANTRY TYPE

The servo driven, three axis modular gantry robotic palletisers are ideally suited for palletising of cartons, HDPE Bags and large cases

Smooth movements are guaranteed to ensure low mechanical strain and speeds of up to 8 movements per minute By picking up 4 or more packs simultaneously the capacity can be considerably increased

Housed within a rigid steel frame, the Gantry palletiser offers a versatile, compact solution for all kinds of palletising applications

On-screen programming allows for easy adding of new stacking patterns or altering of existing stacking patterns

PALLETISER – ROBOTIC

Palletiser robot type is suitable for medium capacity, up to 1600 bags (or) cartons / hour, or in applications where the robot is required to receive bags of several lines at once, or to compile several pallets simultaneously.

By means of the control panel up to 200 different pallet formats can be programmed that are stored in memory to call when needed.

The generation program for layers of each pallet is provided with each palletising robot and allows the user to create new formats.

The grippers for handling bags are specially designed to be manually adjusted depending on the bag size. Fitted with side guides in order to maintain the bag position at all times, in addition to guiding the bag verticality when it is deposited over the layer to make, with much precision as a result regarding the position of the bag.

All movement of the gripper is synchronized with the robot arm movement with the bag remaining clamped at all times, preventing lateral movement.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.