NUCORK PRODUCTS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to NUCORK PRODUCTS P.LTD.

Cork Sheets

Rubberized cork sheets are made of virgin clean granulated cork mixed with Nitrile or Neoprene rubber, which is compressed to form a block, then split into sheets. Cork Rubber is a product with unique characteristics and applications in a wide range of industries, notably automotive, electrical equipment, gas, construction, surfacing, industrial equipment, transformers and railway industries.

Nitrile and Neoprene are common binders used, but special synthetic rubbers like, Silicone can further enhance material performance. As in the past, we would be pleased to assist you in identifying the products that best meets your specifications.

All grade are available in machines shaped and die cut parts made to your drawing and specification. The Products conforms to IS 4253 Part II 2008 RC 70 C & RC 80 C Grade.

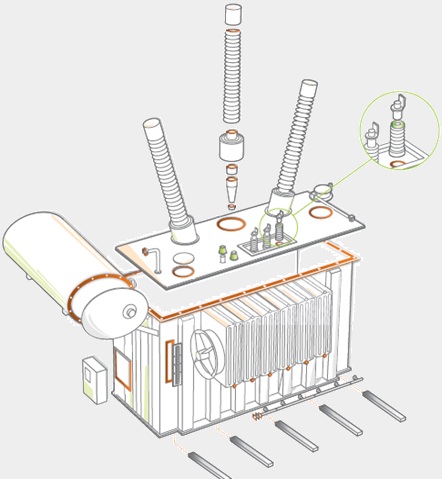

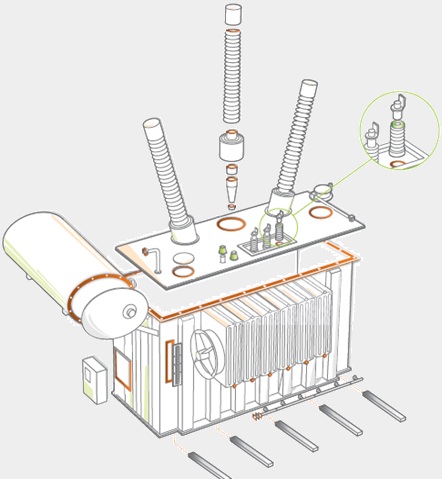

Cork In Transformers

Keeping oxygen and water minimum is the most efficient procedure to extend the life of a transformer.

Utilities are procuring transformer with air cell, breather, thermo-siphon, however bad gasket allows ingress of moisture, abundant oxygen thus drastic reduction in life of transformer.

A good gasket hardly costs 0.3 % cost of the transformer. Bad gasket may consume 30 % life of a transformer. It is therefore prudent to include gasket testing in the quality assurance program.

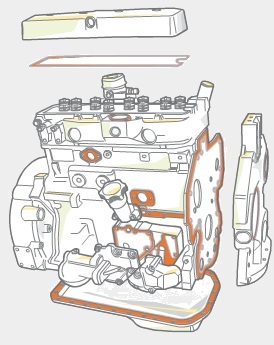

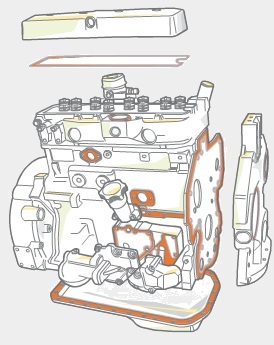

Cork In Automobiles

New cars based on fuel cells, batteries or other engine based types, have usually a flat-bottom body, which is a good characteristic for cork floor applications in this field decreasing weight and carbon footprint.

New solutions for trains, trams and similar transportation vehicles were developed for innovative interior systems (floor, lateral panels, ceiling panels). These solutions are based on the light weight and thermal and acoustic insulation properties of cork. The first product is a natural energy absorber for high impact strikes (rail front ends, impact prone areas on automobiles and trains and carriages). In canoes and kayaks, this has the ability to absorb rock and beach impact while also having an excellent compression recovery. It does not absorb water and does not rot and is resistant to fungal growth.

A project (Mould-cork) is being carried out for the development of car parts (e.g., engine cover part) using cork composites in traditional car industry processes as stamping, injection and thermo-forming. It is predicted to decrease weight, and to increase thermal and acoustic insulation and also vibration damping, for better car performances, better comfort and emissions reduction.

Agglomerated Cork Sheets

Agglomerated cork blocks are made from cork granules bonded together with a polyurethane binder and pressure/heat treated to produce a very strong and flexible product that retains the characteristics of the natural cork, i.e. flexibility, resilience to compression and so on. The cork blocks are cut into sheets with any thickness required above 1.0mm up to 27mm The usual sheet sizes are 945*635mm.This material has a high density of around 230 kgm3.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.