Products & Services

Bi Axial Machine Process

The mould is fitted on the arms of Biaxial Machine A encoded amount of plastic, in dust or liquid form, is deposited in one half of a mould. The mould is closed. The arm progress to oven, the mould is rotated biaxial within an oven. The plastic melts and forms a coating over the within surface of the mould. The arm is removed from the oven and cooled. The mould is opened and the unfilled part is removed.

Rock N Roll Machine

The machine are most suited for production of large tanks. Machine is a single station bi-axial rotational moulding machine with single U arm. U arm is serious duty and supported from both side by attitude housings. Rock n roll machine for Water storage tank, Rock n roll machine, storage tank machine, biggest tanks and Rock n roll water tank machine exporter and rotomoulding machine specially for largest tank

Pulveriser

Description / Specification of Pulveriser

We are involved in offering a wide range of Pulveriser to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Pulveriser. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Single Mill Pulveriser Machine

Description / Specification of Single Mill Pulveriser Machine

We are involved in offering a wide range of Single Mill Pulveriser Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Single Mill Pulveriser Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Twin Mill Pulveriser Machine

Description / Specification of Twin Mill Pulveriser Machine

We are involved in offering a wide range of Twin Mill Pulveriser Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Twin Mill Pulveriser Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Oven Machine

TECHNICAL FEATURES

Oven heated by LPG by shifting nozzle and gas firing system.

Centrifugal blower run by fractional HP, TEFC Motor to provide air for consumption of the gas.

High Voltage Transformer To Ignite Pilot Burner.

Control panel with controls and switchgear available on mild steel.

Less installation area.

Lowest maintenance cost.

Scrap Grinder Machine

ABOUT SCRAP GRINDER MACHINE

Neelam Fabricators is manufacturing large range of Scrap Grinder Machine Machine to provide various polymer-processing industries along with the Rotomoulding Machineries.

Recycled materials either blended with the usual virgin materials in little quantities without affecting finished products. Bearing housing is designed for relaxed working with easy maintenance during operation and provides safety.

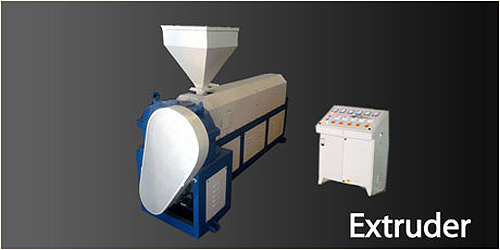

Extruder Machine

The Extruder Machine Machine has a Cool starting defensive control device to prevent gear box, motor and screw safety. The extruder machine will start only after achieving the preset temperature to avoid damages to the screw and gear box, motor orchestrated control for pelletizer motor and extruder motor for unchanging element size avoid over feed or under feed to the pelletizer.

Roto Moulds

ABOUT ROTO MOULDS

Neelam Fabricators is india based company manufacturer and exporter of Rotomoulding and Rotational Moulding Machines, Moulded Plastic Products, Injection Roto Moulds, Blow Roto Moulds, Investment Die Casting Roto Moulds,

Roto Moulds and Dies, Plastic Roto Moulds Because of high quality products, Neelam Fabricators has achieved

important progress in the industry. We thanks to our dedicated staff, who try to create completely perfect

range of plastic products for the worldwide market.