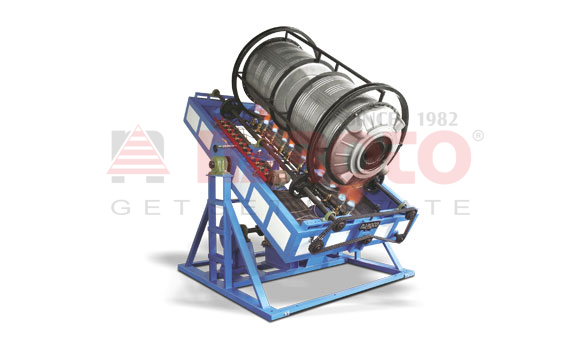

Rotational Molding Moulds

NAROTO has a fully equipped work shop for mould fabrication needs with computerized designs and quality control. We have skilled personnel for sheet metal, bending machine, Argon welding, and the buffing machines to ensure the high quality standards.

We also have pilot plant for testing moulds as per stipulated quality standards. NAROTO offers moulds for products having different shapes like Vertical , Horizontal, Rectangular for water storage. The size of mould for water storage varies from small to large with maximum size up to 40000 liters.

Besides moulds for water storage products, we also offer moulds for wide range of other products including Road barrier, Traffic cone, Safety device, Insulated cooler box, Pallets, Planters, Toilets, Dustbins etc.

Proud to announce 500+ Varieties in Sheet Metal Fabrication, for More Images Contact us.