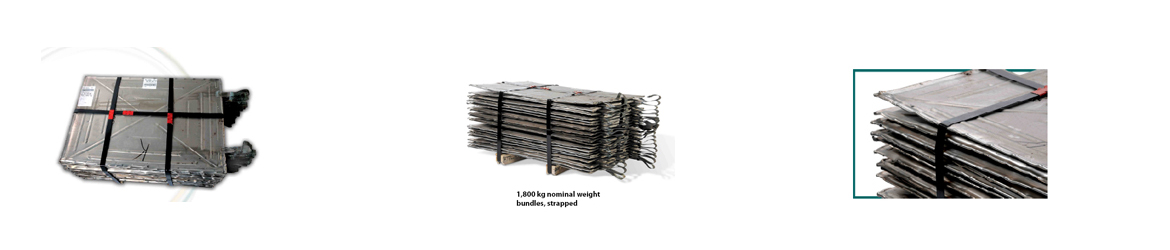

Electrolytic Nickel Cathode

ELECTROLYTIC NICKEL CATHODE (FULL SIZE)

Vale™ electrolytic nickel is the world’s leading brand of electroplating nickel. Full size cathodes are produced by electrolytic refining at Vale’s Thompson Nickel Refinery in Manitoba, Canada. The controlled and consistent quality of the Thompson refining process have established Vale™ Electrolytic Nickel Cathode as an industry standard for general purpose electroplating:

- High purity

- Thickest cathode available (~15 mm)

- Smooth, shiny and defect-free surface

- Produces minimal metallic residues upon dissolution

- Dissolves at 100% anode efficiency in common nickel plating solutions (containing chlorides)

- Must be cut into squares or strips prior to using

- Proven and trusted by the world’s leading electroplaters