MTI MATERIALS P LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MTI MATERIALS P LTD

Electrolytic Nickel Cathode

ELECTROLYTIC NICKEL CATHODE (FULL SIZE)

Vale™ electrolytic nickel is the world’s leading brand of electroplating nickel. Full size cathodes are produced by electrolytic refining at Vale’s Thompson Nickel Refinery in Manitoba, Canada. The controlled and consistent quality of the Thompson refining process have established Vale™ Electrolytic Nickel Cathode as an industry standard for general purpose electroplating:

- High purity

- Thickest cathode available (~15 mm)

- Smooth, shiny and defect-free surface

- Produces minimal metallic residues upon dissolution

- Dissolves at 100% anode efficiency in common nickel plating solutions (containing chlorides)

- Must be cut into squares or strips prior to using

- Proven and trusted by the world’s leading electroplaters

Electrolytic Nickel Squares

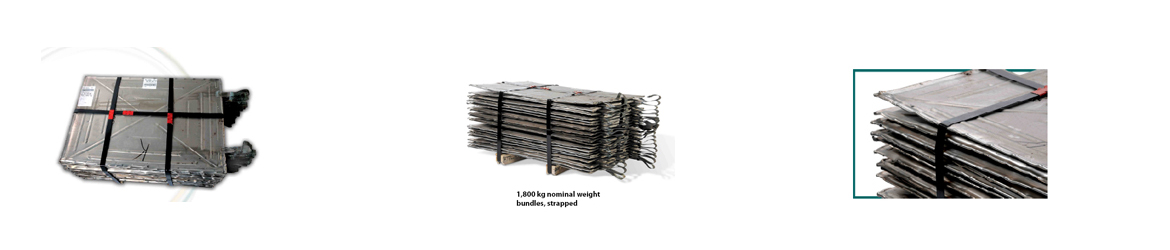

ELECTROLYTIC NICKEL SQUARES 1X1

Vale™ electrolytic nickel is the world’s leading brand of electroplating nickel. Nickel Squares are cut from full size cathodes produced by electrolytic refining at Vale’s Thompson Nickel Refinery in Manitoba, Canada. The controlled and consistent quality of the Thompson refining process have established Vale™ Electrolytic Nickel Squares as an industry standard for general purpose electroplating:

- High purity

- Thickest cathode available (~15 mm)

- Smooth, shiny and defect-free surface

- Produces minimal metallic residues upon dissolution

- Dissolves at 100% anode efficiency in common nickel plating solutions (containing chlorides)

- Added directly to titanium anode baskets

- Proven and trusted by the world’s leading electroplaters

Electrolytic Nickel S Rounds

ELECTROLYTIC NICKEL S-ROUNDS

Vale™ Electrolytic Nickel S-Rounds™ are a high purity form of sulfuractivated nickel specifically designed for electroplating with titanium anode baskets – especially in chloride-free plating baths. The sulphur in this product does not enter the plating solution; it forms an insoluble nickel sulphide residue, which is 100% contained using cloth anode bags, where it acts to remove unwanted copper impurities. The controlled and consistent quality of S-Rounds™, their distinctive shape and size, and the advantages of sulfur activation make Vale™ S-Rounds™ ideally suited for high-end electroplating applications (e.g. high-speed engineering, electronics, electroforming):

- High purity

- Sulfur activation promotes uniform dissolution and low operating voltage, even in chloride-free plating baths

- Unique shape prevents the formation of bridges and voids in the basket

- Unique shape ensures good solution flow and mixing through the basket

- Settles uniformly in basket, ensuring uniform current density and high quality deposits

- Flows easily into regular and shaped baskets of various mesh sizes

- Safe to handle (no sharp edges)

- Dissolves at 100% anode efficiency in common nickel plating solutions – with or without chlorides

- Produces minimal metallic residues upon dissolution

- Proven and trusted by the world’s leading electroplaters

Nickel Plating Chips

NICKEL PLATING CHIPS™ (CDN)

Nickel Plating Chips™ are a high purity form of nickel specifically designed for electroplating with titanium anode baskets. Chips™ are produced by a unique carbonyl gas refining process at the Copper Cliff Nickel Refinery in Sudbury, Canada. The controlled and consistent purity of Chips™ and the advantages associated with its distinctive shape make this product attractive for general purpose plating with titanium anode baskets:

- Carbonyl refining produces the purest form of nickel available

- Unique shape prevents the formation of bridges and voids in the basket

- Settles uniformly in basket, ensuring uniform current density and high quality deposits

- Flows easily into regular baskets with standard mesh sizes

- Safe to handle (no sharp edges)

- Dissolves at 100% anode efficiency in common nickel plating solutions (containing chlorides)

- Proven and trusted by the world’s leading electroplaters

Nickel P Pellets

NICKEL P-PELLETS™ (CDN)

Nickel P-Pellets™ are a high purity form of nickel widely used for electroplating with titanium anode baskets. P-Pellets™ are produced by a unique carbonyl gas refining process at the Copper Cliff Nickel Refinery in Sudbury, Canada. The controlled and consistent purity of P-Pellets™ and the advantages associated with its distinctive shape make this product ideal for general purpose plating with titaniumanode baskets:

- Carbonyl refining produces the purest form of nickel available

- Unique shape prevents the formation of bridges and voids in the basket

- Settles uniformly in basket, ensuring uniform current density and high quality deposits

- Flows easily into regular and shaped baskets with standard mesh sizes

- Ideal for use with automated basket loading devices

- Safe to handle (no sharp edges)

- Dissolves at 100% anode efficiency in common nickel plating solutions (containing chlorides)

Nickel Pellets

NICKEL PELLETS (UK)

Nickel Pellets are a high purity form of nickel widely used in melting applications. Nickel Pellets are produced by a carbonyl refining process at the Clydach Nickel Refinery in the UK. The controlled and consistent purity of Nickel Pellets and the advantages associated with its distinctive shape make this product an industry standard for the production of high-nickel alloys and iron-base alloys:

- Carbonyl refining produces one of the purest forms of nickel available, allowing for its use in the most demanding applications in the aerospace, electronic and nuclear industries

- High nickel content and low impurity levels allow for its addition at any stage of the alloy-making process

- Distinctive shape results in high packing density, easy flow and permits semi- and fully-automated handling operations, such as transfer from bulk storage to weighing and furnace charging stations

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.