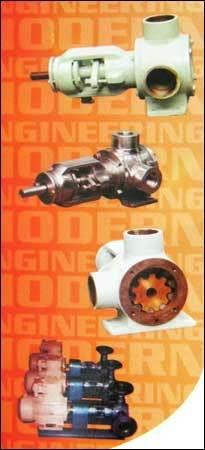

Internal Gear Pumps

We are among the pioneers in the industry for manufacturing and supplying Internal Gear Pumps. The offered gear pumps are made in tune with the industry standards and have earned us a huge clientele. These pumps are durable, resistant to corrosion and offer hassle-free operations. The offered gear pumps are ideal for a gamut of industries including oil, petrochemicals, paints, inks and chemical.

Features:

- Hassle-free operations

- Longer service life

- Robust design

Specifications:

- Sizes Available: 1 inch, 1.25 inch , 1.5 inch, 2 inch

- Material: MS & SS

Advantages:

- Only two moving parts

- Only one stuffing box

- Non pulsating discharge

- Excellent for high viscosity liquids

- Pump is fireproof

- Operates well in either direction

- Can be made to operate with one direction of flow with either rotation

- Single adjustable end clearance

- Easy to maintain

- Flexible design offers application customization

Applications:

- All varieties of Fuel Oil & Lube Oil

- Resins And Polymers

- Solvents

- Paints

- Inks and Pigments

- Varnish

- Castor Oil