MINI MAX DOSING PUMPS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MINI MAX DOSING PUMPS

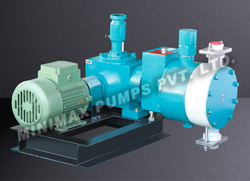

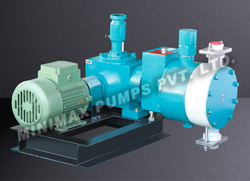

Plunger Type Pumps

We offer our customers with premium quality plunger type pumps, which are known for their efficient performance. Customized as per the specifications of our clients, these are known to deliver maximum performance and gave a long performing life. We manufacture a wide range of plunger type pumps for hygienic application which is designed to achieve high standards of performance. These can withstand continuous duty operations & guarantees trouble free performance.

Specifications of our plunger pumps are :

• High flow rates of 0-10,000 liters/hr

• High pressures of 400 Kg/sq. cm

• Steady State metering accuracy of +/-1 % of pump output

• Single setting of stroke from 10% - 100% by interlocking mechanism

• Reproducibility (Repeatability) better than +/-2.5% of set point

• Easily compatible with most of the fluids

• Positive return of plunger and variable stroke mechanism allows linear relationship between control stroke

setting and stroke length

• Low NPSHR requirement

• Simplex and multiplex arrangements of pumps with common drive available for universal use

• Heating or cooling jackets for liquid head is also available for highly viscous at room temperature

Liquid contact materials (Wetted Parts) :

• AISI 304, 316 • Monel • Alloy 20 • Hast alloy B • Polypropylene • Hast alloy C • Titanium • GFT

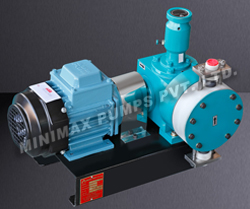

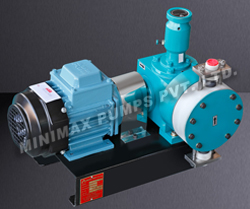

Hydraulic Actuated Diaphragm Pumps

Hydraulic Actuated Diaphragm Pumps Leveraging on our competent design engineering and advanced technological machinery, we are manufacturing & delivering extensively efficient and high performance Hydraulic Actuated Diaphragm Pumps to our countless clients. Customized as per the specifications of our clients.

Hydraulic Actuated Double Diaphragm Pumps

Our wide range of comprises of Hydraulic Actuated Diaphragm Pumps which have been manufactured adopting superior quality raw material. These can be customized as per the specifications of our clients and have a long performing life.

Liquid Contact Materials (Wetted Parts) :

• PTFE Diaphragm

• AISI 304

• AISI 316

• Monel

• Alloy 20

• Hast alloy B

• Propylene

• Hast alloy C

• Titanium

• GFT

• PP

• PTFE

• PVC

Technical specifications and features of our pumps are :

• Double diaphragm with reputure indication also available

• Can easily handle most of the liquids

• Simplex and multiplex arrangements of pumps available for universal use

• Heating or cooling jackets for liquid head available

• Pressure (Kg./Sq. Cm.) Max 80

• Mini max make HD type diaphragm gland less pumps

• Leak free operation

• Flow rates of 0To 800 LPH, & High discharge pressures of 180 Kg/sq. cm. can be achieved

• Steady State metering accuracy of +/- 1% of pump output, at single setting of stroke from 10%-100%

• Reproducibility (Repeatability) better than +/- 1.5% of set point

• Inbuilt Pressure Relief & vacuum valve on the hydraulic side to safeguard system

Mechanically Actuated Diaphragm Pumps

We offer our customers with premium quality mechanically actuated diaphragm pumps, which are known for their efficient performance. Customized as per the specifications of our clients, these are known to deliver maximum performance and gave a long performing life. We are engaged in manufacturing a wide range of Mechanically Actuated Diaphragm Pump. These have been customized as per the specifications of our clients and known to deliver maximum efficiency.

It comprises of following features :

• Flow range from 0 LPH up to 1150 LPH for different models &

• Pressure - maximum 4 Kg./Sq.Cm

• Leak free

• Steady state metering accuracy of +3%, of pump output, at single setting of stroke from 10% - 100%

• Reproducibility (repeatability) better than + - 3% of set point

• Suitable to handle most corrosive fluids

• Teflon diaphragm supported by a steel core & reinforced by vulcanized chemical & temperature resistant EPDM material

• Nylon webbing ensures better life & flexibility

• Plunger directly connected to diaphragm to create reciprocating motion

• Simplex and Multiplex arrangements of pumps available for universal use

Liquid Contact Materials (wetted Parts) :

• PTFE Diaphragm • AISI 304, 316 • Monel • Alloy 20 • Hast alloy B • Polypropylene • Hast alloy C • Titanium • GFT • PTFE • PVC

Skid Mounted Dosing Systems

We manufacture and design a complete skid mounted dosing systems Which saves our clients time to search individual items.

We offer a wide range of Skid Mounted Chemical Dosing System which is a perfect solution for all chemical dosing problems.

Skid Mounted Chemical Dosing Systems

These systems are fabricated using superior quality raw material and possess following parts and features :

• Solution Preparation Tank-Single or compartment

• Single or multiple chemical dosing pumps

• Stirrer (Agitator)

• Valves, Fittings

• Interconnecting piping

• Instruments such as pressure gauges

• Level gauges

• Level switches

• PRV

• Sensors

• VFD etc.

Flocculant Dosing Systems

These systems consists of solution preparation tank with dosing tank.

Also available with :

• Solution Preparation Tank-Single or compartment

• Chemical Dosing Pumps Single or Multiple

• Stirrer (Agitator)

• Valves

• Fittings

• Interconnecting Piping

• Instruments like Pressure Gauges

• Level Gauges, Level Switches

• PRV

• Sensors

MODEL OF TANK:- HDPE, SS316, SS304, FRP, P.P.

Skid Mounted Chemical Dosing Pumps

We offer complete solution to our clients for chemical dosing applications by manufacturing a wide range of Skid Mounted Chemical Dosing Pump.

These can be customized as per the specifications of our clients and possess following parts :

• Single or Compartment Solution Preparation Tank

• Chemical Dosing Pumps Single or Multiple

• Stirrer (Agitator)

• Valves

• Fittings

• Interconnecting Piping

• Instruments like Pressure Gauges

• Level Gauges, Level Switches

• PRV

• Sensors

• Control panel including interconnecting cabling

Lp And Hp Dosing Skids

Description / Specification of Lp And Hp Dosing Skids

We are involved in offering a wide range of Lp And Hp Dosing Skids to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Lp And Hp Dosing Skids. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Biocide Mill Sanitation Dosing Pumps

Description / Specification of Biocide Mill Sanitation Dosing Pumps

We are involved in offering a wide range of Biocide Mill Sanitation Dosing Pumps to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Biocide Mill Sanitation Dosing Pumps. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Solenoid Operated Dosing Pumps

We are one of the leading names engaged in manufacturing a wide range of Solenoid Operated Dosing Pump that have been designed with superior quality raw material. These can be customized as per the specifications of our clients and are known to deliver maximum performance.

These can be customized as per the specifications of our clients and are known to deliver maximum performance.Features are:

It comprises of following features :

• Max flow rate up to 40 LPH.

• Pressure of Max 08 Kg/Sq. Cm.

• Air Bleed arrangement built into pump head

• Double ball NRV ensure long life & better accuracy

• Operating voltage range viz.180-280 V

• Automatic voltage compensation to ensure dosing consistency

• Receive the 4-20 m amp

• Fault L.E.D. gives visual indication of blown fuse, low level in chemical tank over-heating of pump

• Level Switch inter-lock facility available

• Relay output: Potential free change over contact, which activates in event of pump malfunction

• Unlimited dry running capability

• Compact & Requires less space

• Easy to operate and maintain

Dosing Pumps

These can be customized as per the specifications of our clients and are known to deliver maximum performance. Features are :

It comprises of following features :

• Max flow rate up to 40 LPH.

• Pressure of Max 08 Kg/Sq. Cm.

• Air Bleed arrangement built into pump head

• Double ball NRV ensure long life & better accuracy

• Operating voltage range viz.180-280 V

• Automatic voltage compensation to ensure dosing consistency

• Receive the 4-20 m amp

• Fault L.E.D. gives visual indication of blown fuse, low level in chemical tank over-heating of pump

• Level Switch inter-lock facility available

• Relay output: Potential free change over contact, which activates in event of pump malfunction

• Unlimited dry running capability

• Compact & Requires less space

• Easy to operate and maintain

High Pressure Triplex Pumps

We are one of the leading names engaged in manufacturing a wide range of High Pressure Triplex Pumps (High Pressure Pumps) that have been designed with superior quality raw material. These can be customized as per the specifications of our clients and are known to deliver maximum performance.

We manufacture a wide range of High Pressure Triplex Pump which has been fabricated using superior quality raw material. These are high pressure pumps with 90% efficiency with reduced operating costs and are available in three plungers with reinforced seal and used ceramic plunger for tight alignments

Features :

• Smooth and consistent flow assured

• +90% pulsations eradicated

• Compactly Designed

Screw Pumps

We manufacture precision engineered range of Screw Pumps that are compact, light in weight and available in different sizes and material of construction. These are used to transfer all type of liquid which are low or high viscous, neutral or aggressive media, with or without solid or fibrous matter. They are very well suited to all types of industries.

Hygienic Pumps

Our wide range of Hygienic Pumps (Model-1) are fabricated from superior quality raw material that are self priming , rotary, valve less positive displacement pumps and have only two pumping elements: the rotor and the stator. When rotor turns, cavities are formed between rotor & stator. Once the rotor moves the chambers turn helical in an axial direction, i.e. backward of forward according to direction of rotation. This is through these pipes that the liquid is pumped with produces a pulsation less, turbulence free flow. Providing high vacuum in the suction pipe, these acts as self-priming pumps and this is the configuration that makes these pumps ideally suited for high suction lift.

Features of this model are:

• Higher mechanical efficiency

• Large properties of solids handled at a time

• High proportion of gas and entrapped air handled at a single time

• Capability to handle large properties of solids

• Can handle high proportion of gas & entrapped air

• Less radial thrust

• Low rubbing velocity

• Less wear

• Lower axial thrust

• Smaller unbalance

• Minimized noise production

• Minimal failure

• Sealed against liquid

• High torque transmission

• Longer Life

• Compatible to different liquids

Technical Details:

• Capacity: 250 Cu. M/Hr

• Head: 48 Kg/sq. cm

• Temperature: Up to 200 Deg C

• Viscosity: Up to 5,00,000 CST

Mono Block Pumps

We are one of the leading names engaged in manufacturing a wide range of Solenoid Operated Dosing Pump that have been designed with superior quality raw material. These can be customized as per the specifications of our clients and are known to deliver maximum performance.

Mono Block Pumps - ANTICR

Item Code : ANTICR

We are engaged in offering Mono Block Pump–ANTICR that is durable and highly efficient. Designed as per latest technology, these is no over heating of the motor and it offers noise free operation. High quality ball bearings are use for longer life. The pump is applicable in irrigation, hotel, industrial and commercial complexes and in water supply schemes for apartment buildings and housing societies

Note : Monoblock construction pump (Pump with motor) Accessories not required.

Advantages :

• All pumps, shaft are available with sleeves of different materials compatible with the liquid handled.

• All pumps are available with Externally mounted balanced mechanical seal or Teflon Gland Packing or

internal mechanical seal with elastomer bellows.

• Volute & impellers are injection moulded polypropylene material with smooth hydraulic passage.

• High quality ball bearings are use for longer life.

• Cooling arrangement for mechanical seal.

Centrifugal Pdf Pumps

Manufacturer & Exporter of CENTRIFUAL PUMP & Centrifugal PDF Pump. Our product range also comprises of Plunger Type GMP Pumps, Hydraulic Actuated Diaphragm Pumps and Mechanically Actuated Diaphragm Pumps.

PDF bare shaft pumps flow rate 10m3/hrs 30 mtrs gead

MOC- PVDF with support liquidated

Handling corrosive acid.

Pressure Relief Valves

We offer a precision engineered range of Pressure Relief Valves which are widely used in areas where high pressure and capacity is required. Further, these can also be used in air, gas, liquid and steam based systems.

Available at competitive prices, these possess following features :

• Higher capacity level

• Pressure relief

• By-pass & overpressure protection

• Steam, air, gas and liquid settings

• Safety relief valve spring loaded

• Cast construction with flanged connections for nominal pressure ratings up to PN 40/PR #150

• Precision lapped metal-to-metal beveled seating

• Lifting lever

• Stainless steel springs

• Adjustable blow-down

• Sizes: ½ to 2 in screwed connection

• Testing is carried out on pneumatic test bench for steam, air &gas applications

• For liquid service, valves are tested on hydraulic test bench

• Testing standard as per API - 527

• MOC: CS/ SS

P.P. Pressure Relief Valves

Offering a wide range of Pressure Relief Valves (Model-MPRL), we have been successfully catering to the requirements of various industries.

These are used in areas high pressure and capacity requirement areas and possess following features :

• Precision lapped metal-to-metal beveled seating

• Lifting lever

• Stainless steel springs

• Adjustable blow-down

• Sizes: ½ to 2 in screwed connection

• Testing is carried out on pneumatic test bench for steam, air &gas applications

• For liquid service, valves are tested on hydraulic test bench

• Testing standard as per API - 527

• MOC: CS/ SS

• Higher capacity level

• Pressure relief

• By-pass & overpressure protection

• Steam, air, gas and liquid settings

• Safety relief valve spring loaded

• Cast construction with flanged connections for nominal pressure ratings up to PN 40/ PR #150

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.