MICROFILT INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MICROFILT INDIA P.LTD.

On Line Housing

On line housings are designed for vertical online mounting primarily for air vents etc. The housings are made of high quality SS316L stainless steel (for Pharma / biotech applications) and other suitable MOC as required. Housings come with gaskets and O-rings compounded only from FDA approved materials. A choice of easy to use sanitary diaphragm valves for steam inlet and condensate drain is provided to be used during sterilization of the cartridge and the housing for Pharma & Biotech application. The Inlet and outlet end connections are standard triclamp connections. The housing is capable of incorporating single cartridges of multiple lengths to suit required flow rates. Housings can accommodate a single round of filter cartridges of 5”,10”,20”,30”,40” inches long. Multiple rounds are available on request.

T Line Housing

T-Line housings are designed for providing a robust solution for critical filtration applications. The housings are made of high quality SS316L grade stainless steel (for Pharma / biotech applications) and other suitable MOC as required, to be compatible with the contact fluid. Housings come with gaskets and O-rings compounded only from FDA approved materials. The housing features Triclamp/swing bolts for ease of opening and closing the housing dome. The housing also features a choice of sanitary and non-sanitary vent and drain valve options. The inlet and outlet end connections are either flanged or standard triclamp connections. The housing is capable of incorporating single or multiple cartridges of multiple lengths to suit required flow rates. All wetted parts with customized MOC & customized finish. Housings can accommodate single or multiple filter cartridges of 10", 20",30" or 40” long.

Special T Line Housing

Special T-Line housings are designed for sanitary and non-sanitary range of air and gas filtration applications. The housings are made of high quality SS316L stainless steel (for Pharma / biotech applications) and other suitable MOC as required, to be compatible with the contact fluid. Housings come with gaskets and O-rings compounded only from FDA approved materials. The housing can also be provided with a choice of sanitary and non-sanitary vent and drain valve options. The Inlet and outlet end connections are either flanged or standard triclamp connections. The housing can fit one single cartridge of multiple lengths to suit required flow rates.

Z Line Housing

Z Line housings have been designed for general purpose & cost effective filtration for industrial utility application. All housings are manufactured using corrosion resistant SS 316L or SS 304 grade steel other MOC is available as customer required. Housings are designed to accommodate 3 multiple rounds of cartridges with lengths varying from 10” to 40” and provides flexibility over a wide range of flow rates with minimal pressure drop. Housings can accommodate a multiple rounds of filter cartridges of 10", 20", 30" or 40" inches long. All gaskets and polymers compounded as per USFDA approved polymers.

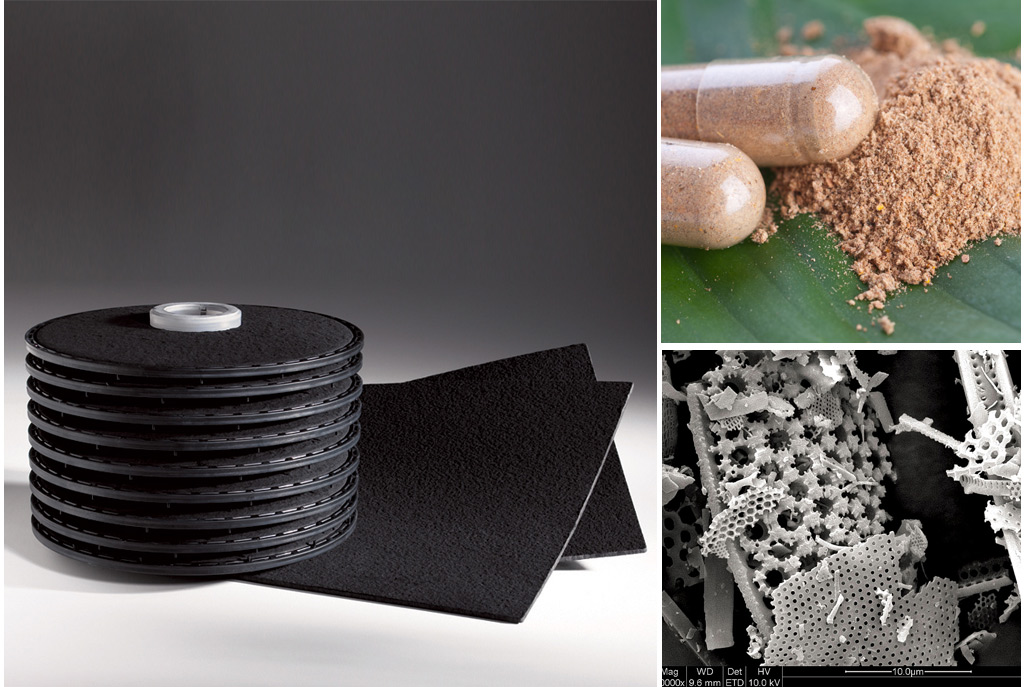

Lenticular Housing

Lenticular housings are designed for providing a robust solution for critical clarification and filtration applications with the help of CMDF module i.e. Charged Modified Depth Filter. Lenticular housings are made of high quality SS316L stainless steel, with internally with external polished finish surfaces. Housings come with gaskets and O-rings compounded only from FDA approved materials. For corrosive fluid we offer wetted part to be PP/PTFE/PVDF. The housing features swing bolt/clamp design for ease of opening and closing the housing dome. The housing also features a choice of Sanitary and Non-sanitary design. The Inlet and outlet end connections are either flanged or standard triclamp connections. The housing is capable of incorporating single or accommodative multiple modules to suit a wide range of required flow rates. Choice of CMDF (cellulose/ carbon) Module available as per custom design.

CMDF modules contains advanced cellulose based depth filtration media, designed to retain contaminants by both mechanical entrapment and electrokinetic adsorption. This filter media is made up of cellulose, Filter Aid and binder resin.

Bag Filter Housing (Bag Filter)

47261.jpg)

MICROFILT bag filter housings are designed for varied filtration processes ranging from pharmaceuticals to paints. They are designed for heavy duty with side or top entry for easy connections. The swing bolt design enables quick access to the filter bags enabling easy removal and installation. Designed to suit various flow rates, the bag filters come in various models ranging to accommodate single or multiple bags. Bag filter housings are cost-effectively designed to cater needs with various MOC. Bags are easily removable with cake to enable disposable or recovery and also provide quick opening and closing of the dome hence less labour. MICROBAGS are also available which is the most economical filtration media for filtration of most of fluid including highly viscous fluids like oil & fluids with high levels of solid content. Housings can accommodate 1-5 bags or more of bags of Size 1 and Size 2.

Presure Vessels

The Laboratory filtration tools range comprises of Constant Flow Kit, Constant Pressure Kit, SDI kit, Pressure Vessels, Bench top models of Cross flow system , MAS(MICROFILT automated strainer),Candle filter & Nutsche filter. These are completely bench scalable systems with flexibility to use any filtration media with multiple combination to arrive at optimum filtration system.

MICROFILT Pressure Vessels with varying sizes. It used for holding sterile /non-sterile liquids. Ideal accessories for filtration of small size batches.

Standard various capacities are available 1, 2, 3, 5, 10, 15, 10, 25, 40, 50, 60, 100, 150, 200, 250 (litres).

Customize capacities also available.

Slit Density Index Kit

MICROFILT provide a SDI test kit is to assess the extent of suspended particulate (solids and colloidal) contamination in water & can be applied in process solutions also. A SLIT DENSITY INDEX (SDI), also referred to as Fouling Index. Although most systems have some pre-treatment these fine particles are responsible for the fouling of reverse osmosis membranes. In order to measure the degree of this fouling problem, a concept called Silt Density Index is used. High Index waters are measure of dirty, and contaminated, low index waters are clean and indicate suitability for the process. The SDI of the feed water is directly related to the filtration costs.

MICROFILT SDI Kit consist of:

Inexpensive flow control kit.

Calibration and shutdown are made much easier by using a valve to control the water flow.

Pack of 25 membrane.

Required Instruments, valves etc.

Filter Holder

MICROFILT Filter Holder is provided for the sanitary/non-sanitary filtration application in various industry. This is made up of SS 316 or customize design. We provide Filter Holder which is completely disassembled so as to clean easily. Our Filter Holder allow you to seal the filter media by hand with tightening and locking wing nuts. Filter holder are of varying sizes 47mm, 90 mm, 142mm, 293 mm.

MICROFILT Filter Holder Consist of:

This pad holder is completely disassembled which is easy for cleaning.

Filtering small batches of liquid therefore use of separate pressure filtration vessel minimizes.

Compact, user friendly & ideal for clean rooms.

Constant Pressure Kit

Constant Pressure Kit can assist in determining the appropriate filtration system for a specific application at constant pressure. The Constant Pressure Kit requires only an electrical power source for the compressor & 3-4 feet of bench space.

MICROFILT Constant Pressure Kit consists of:

Appropriate volume pressure vessel with accessories.

Flat sheet holder for depth as well as surface filtration. Customized holders also can hold filter cakes.

Required Instruments, valves etc.

Constant Flow Kit

Constant Flow Kit can assist in determining the appropriate filtration system for a specific application at constant flow. The constant flow kit requires only an electrical power source for the pump & 3-4 feet of bench space.

MICROFILT Constant Pressure Kit consists of:

Appropriate pump with accessories.

Flat sheet holder for depth as well as surface filtration. Customized holders also can hold filter cakes.

Required Instruments, valves etc

Bench Top Cross Flow Kit

Bench Top Cross Flow Filtration Kit consists of microfiltration ultrafiltration combination with nanofiltration. Designed to suit the critical requirement of industry specific application right from high end Biotech system to a very low end effluent treatment. This system contain ceramic and polymeric membrane varying molecular cut off rating depends on application.

Useful for laboratory scale and pilot scale application.

Easy to installation.

Easy scalable.

Bench Top Mas (Microfilt Automated Strainer) Filter

Filter 47268.jpg)

Bench scale kit of MAS 207 is available which is most useful for laboratory practices.Microfilt Automated Strainer (MAS) are offered in several configurations requiring filtration from more than 1000 microns to less than 20 for liquids very high in viscosity in excess of 1 lac cp.MAS filters are ideal for continuous flow (and therefore batch) applications. Various MAS model are also available.

Eliminates the need for disposable media for many applications.

Mechanically cleaned in place filter.

Choice of various metal cleanable media.

Bench Top Nutsche Filter

Laboratory NUTSCHE filter, which is useful for various trial practices in laboratory & pilot scale. NUTSCHE filter batch filtration technique that uses vacuum / pressure in a closed vessel this is mostly used in chemical and pharmaceuticals industries. The system consists of closed filter vessels with filtration media. In this filter, filtration solid/liquid slurry aided by pressurizing the vessels /applying the vacuum.

Easy to handle/operation.

Easy product/ cake can be recovered cleanly.

CIP/SIP is possible.

Useful for laboratory & pilot scale practices.

Bench Top Candle Filter

MICROFILT provide small CATRECO TM as solid/liquid separation kit especially for laboratory bench scale operation. CATRECOTM is a MICROFILT system specifically designed to cater to filtration needs of organic process industries manufacturing fine chemicals, bulk drugs, drug intermediates, agrochemicals, dyes intermediates etc. CATRECOTM is bulk solid Recovery/removal System. Specific to recovery of catalysts for Hydrogenation which recycles the expensive catalysts used in the reaction.

Minimum hold up.

Enclosed system with compact design.

Backwash cycle.

Sparkler Filter

MICROFILT’S Horizontal Filter Press also known as SPARKLER filter, redefine filtration through compactness, ease of operation and robust engineering. Which are ideally suited for filtration of syrup, liquid, chemicals, oil beverages etc. the filter presses are totally enclosed, leak proof assembly. Horizontal filter press, Filter cartridge assembly made of no. of disc Type Filter plates perforated filter screens, filter media, Inter locking cups with pump & piping, mounted on trolley. The swing bolt design ensures air tight sealing and also gives the operator the ability to quickly assemble and disassemble the filtration system. Jacketing option can be provided for heating or cooling the product. The zero hold up models ensure all the fluid is transferred to the filtrate side without any holdup. Skid mounted assembly ensures portability and compactness. The filter presses are available in various MOC to suit the product to be filtered and the process required. Various nominal diameters are available 8, 14,18,24, 33 inches with a surface

Candle Filter System (Candle Filter System)

47272.jpg)

The Candle Filters are, as all pressure filters, operating on a batch cycle. Candle Filters is the cylindrical shape of the elements that retain the formed cake. Candle Filters are very well suited for handling flammable, toxic and corrosive materials since they are enclosed and designed for hazardous environments when high pressure and safe operation are required. Candle Filters are available in various sizes. Candle Filter consists of three major components:

The vessel

The filtering elements

The cake discharge mechanism

Backwash cycle is for remove the cake

Selection Criteria

Candle Filters are best selected:

When minimum floor space.

When the liquids are volatile and may not be subjected to vacuum.

When there is a risk of environmental hazard

Higher yield & catalyst recovery.

When the cake may be discharged either dry or as a thickened slurry.

Nutsch Filter

Nutsch filter batch filtration technique that uses vacuum/pressure in a closed vessel is mostly used in chemical and pharmaceuticals industries. The system consists of closed vessels with variety of filter media. In this filter solid/liquid slurry is aided by pressurizing the vessels/applying the vacuum. Liquid is passed through the filter and solid concentrated on filter media i.e. cake is retained on filter medium. Synthetic filter cloth, filter pad or the metallic filter is mostly use as filter media. This filter is specially designed for solid liquid separation. We offer cleanable, non-fibre/particle releasing Sintered SS316L filter discs as a option. This is a major advantage in applications requiring filtration of antibiotics, vitamins etc. in sterile rooms where ordinary centrifuge cannot be used and use of conventional filter cloth is ruled out. Nutsch filters are designed to facilitate flexible discharge.

Microfilt Automated Strainer

Microfilt Automated Strainer (MASTM) are offered in several configurations requiring filtration from more than 1000 microns to less than 20 for liquids very high in viscosity in excess of 1 lac cp. MAS is mechanically cleaned-in-place filters, eliminates requirement of high area filter. It continuously clean the filter surface and solids can be intermittently discharged from discharge point. When processing water and water like liquids where a low initial investment is demanded, the Standard Series delivers tremendous benefits. Available in 207, 540, 801 and 1602 models, the Standard Series enables operation at a vast range of flow Rates and retentions.MAS filters are ideal for continuous flow (and also batch) applications. Range of filter media available, slotted wedge wire and sintered wire mesh. Micron rating of filter media variation depends on type of application.

Plate And Frame Filter Press

MICROFILT’S filter presses are characterized by their robust design and engineering. Designed to increased cake holding capacity by the use of screen. The use of screen greatly enhances the flow geometry of the plates. the innovative, rouge design optimized screen consists of an open filtration area that is 40% larger than the perforated screen design. This results in optimised flow path and enables full use of the filtration area. Increased filtration area directly results in increased flow. The fully enclosed design allows for CIP and SIP cleaning. Mechanical dehydration also results in higher yield and lowering of the residual moisture in the filter cake. The filter presses are precision machined for effective sealing to ensure zero leakage.

Cross Flow Filtration System

MICROFILT have a advanced MICROSSTM as CROSSFLOW filtration system which is also known as tangential flow filtration. Cross flow membrane filtration is pressure driven technology which is used for to separate/concentrate solids and molecules of colloidal size up to ions. In cross flow technology first the separation of suspended solid particle from inlet stream, For this mostly ceramic membrane is used. This is also called as MICROFILTRATION (MF). For further separation, fractionation and concentration of smaller molecules like protein, salt, sugar, colouring agent etc. Polymeric Spiral membrane is used.

In this system feed is pumped through the channels, inside the channels there is an active membrane layer. The membrane layer separate all the element being bigger than the membrane pores, filtrate is permeate through membrane layers and support. Boundary of formation of cake thickness is control by cross flow of retentate. Cross flow filtration kit consists of microfiltration, ultrafiltrtion combination with nanofiltration, designed to suit the critical requirement of industry specific application right from high end Biotech system to a very low end effluent treatment.

C.M.D.F. Filter

CMDF filter modules contains advanced cellulose based depth filtration media, designed to retain contaminants by both mechanical entrapment and electrokinetic adsorption. CMDF filter media is composed of high surface area filter aids embedded in a cellulose fiber matrix. The manufacturing process involves forming a filter matrix with an interconnected filtration structure with charged electro-kinetic capture mechanism. This results in porous and tortuous network capable of removing bacteria, particulate, cellular debris and submicron contaminants to a level which mechanical screening alone cannot achieve. Microfilt CMDF Module filter is available in 9 cell, 12 cell, 14 cell, 16 cell and as per customer requirement. Microfilt CMDF series filters are made for a broad field of solid liquid separation applications. The technology is designed for high service life of filter media and equipment. Its high filtration performance, top manufacturing quality and comprehensive set of certificates meet the high standards sensitive applications.

C.M.D.F. Carbon Filter

Microfilt charged modified depth filter carbon modules are comprised of highly porous activated carbon combined with cellulose fibers. The unique formulation process creates filter media with exceptionally high void volume allowing the module to be efficient in decolorizing fluids and absorbing a wide array of unwanted contaminants from process streams. Microfilt CMDF carbon series modules eliminate many of the common process and safety issues associated with bulk activated carbon technology. Each grade of CMDF carbon media is formulated to optimize retention and flow properties to meet an application’s requirements. Manufacturing by means of an advanced, highly automated production process results in very consistent product quality and filtration performance. Microfilt CMDF carbon Module filter is available 12”and 16” diameter with customized area and as per customer requirements.

Microbag Filter

MICROBAG Filter bags are the most economical filtration media for filtration of highly viscous fluids like oil and for fluids with high levels of solid content. MICROBAG has high surface area and dirt holding capacity .MICROBAG filters are fabricated using high dirt holding media that provides consistent particle retention. Longer life reduces purchase cost, downtimes due to change outs, and disposal costs and thereby reducing the overall filtration cost as compared to cartridge filters. MICROBAG filter’s unique, graded layering of media starting with a built in pre-filter inner layer and progressing to the tighter outer layer ensures the particles are systematically removed as fluid travels through multiple layers with each individual layer performing a special function.

Metallic Filters

MICROSINT-SS Sinter powder metals filters offers a wide range of sintered metal powder filtration products for a variety of applications and industries including chemical processing, refining, hot gas, pharmaceuticals, steam service, and many more. A unique sintering technology is used to create products with significant performance, durability, and reliability advantages. MICROSINT-SS, a industry exclusive, allows for removal of sub-Micronics particles without the high pressure drop.

Membrane Filters

MICROFLUORO is an absolute-rated polytetrafluoroethylene (PTFE) membrane filter that offer the highest level of assurance of chemical compatibility and filtration performance in aggressive chemicals, prolonged hot air service and other severe process conditions. MICROFLUORO offers superior flow rates and long service life. The highly porous membrane is inherently hydrophobic and offers maximum chemical compatibility with minimal extractable in a wide range of fluids and applications. Support components are all-polypropylene, and all- PTFE option is also available.

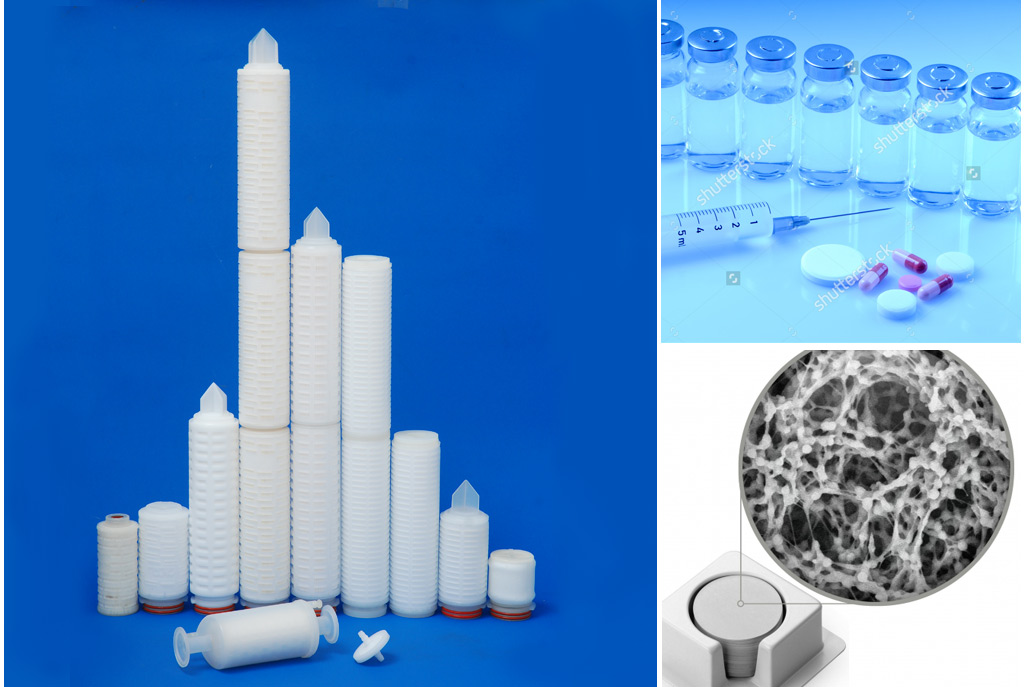

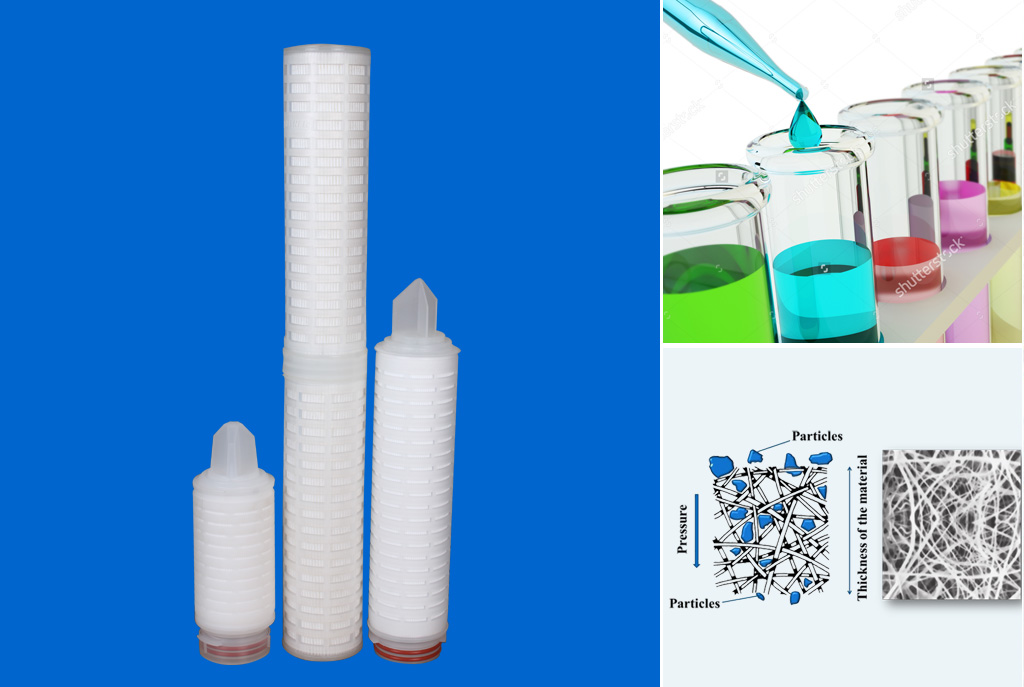

Pleated Filters

MICROPP pleated cartridge has been developed to meet the process needs and throughput requirements of the Pharmaceutical, Food & Beverage, Electronics, Chemical, and other critical industries. MICROPP pleated cartridges are used to filter liquids where high efficiency, low pressure drop, robust debris holding capacity and long life are essential. These filters can be used as a pre-filter or as a final filter depending on the application. MICROPP filter cartridges deliver high filtration efficiency and consistent filtration of fluids in a wide range of applications. All cartridge hardware components are made up of polypropylene and approved for use in critical process applications. MICROPP pleated cartridges are manufactured and assembled in a clean room environment to minimize the possibility of contamination. MICROPP cartridges are available in a wide range of configurations and end connections to fit most of the commercially available filter housings.

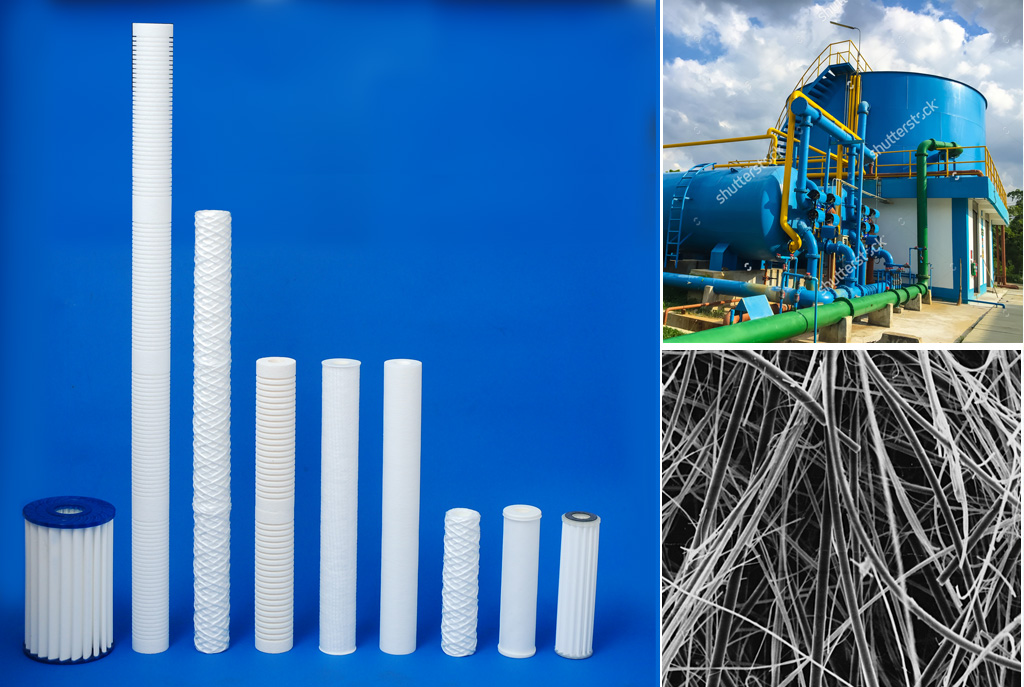

Depth Filter

MICROPOLY-MBD spun bond Depth filter Cartridges are made of 100% polypropylene with no additives or surfactants used that can cause foaming or other undesirable effects to the filtrate quality. With true graded density construction these cartridges have the highest dirt holding capacity possible. Melt blowing (MB) is a process for producing fibrous webs.

MICROPOLY-TBD filter cartridges are manufactured using a unique technology using thermally bonded component fibers resulting in a rigid complex filter matrix. The patented construction of this filter cartridge provides consistent filtration and eliminates pore size variability and media migration.

MICROPOLY-PWD Filter Cartridges are made from high quality, FDA compliant polypropylene filter media, wound to precision requirements. They can hold more contaminants resulting in fewer filter changes.

MICROREBO-RBD cartridge has been developed by ‘intrinsically bonding cellulose fibers’ together with a pure resin. By cross-linking cellulose and resin, a filter of great strength has been developed that can be used with most liquids and chemicals.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

47261.jpg)