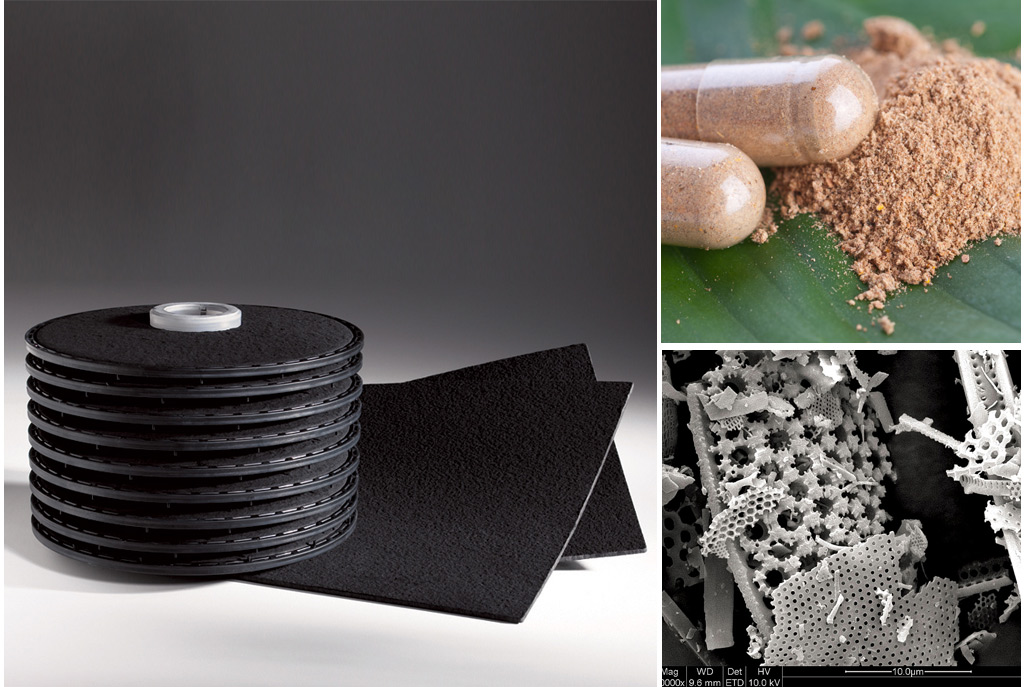

C.M.D.F. Filter

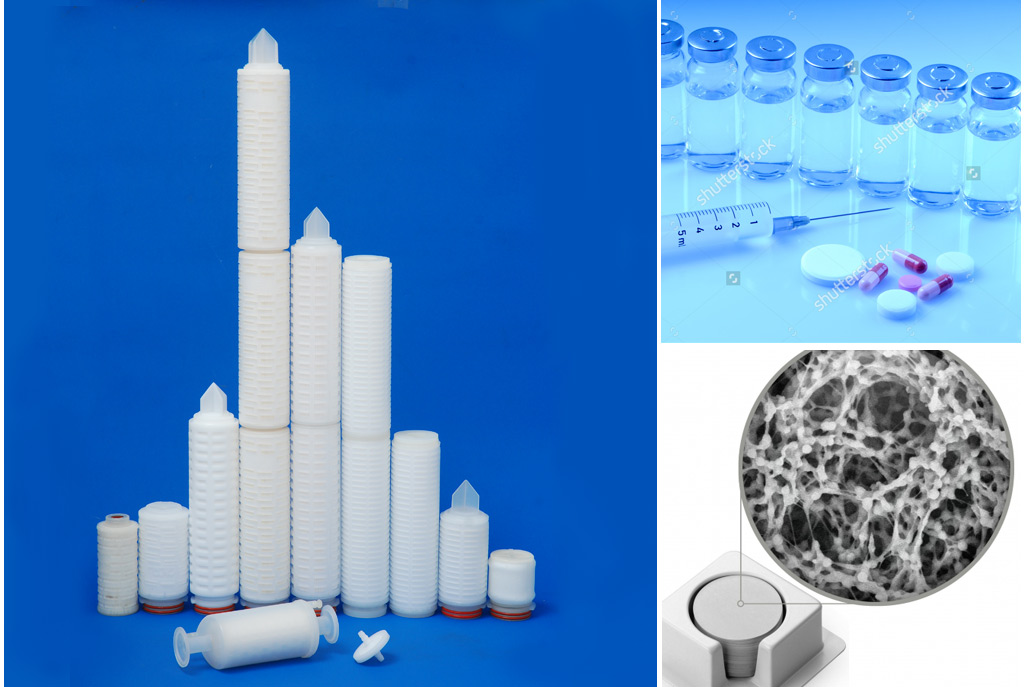

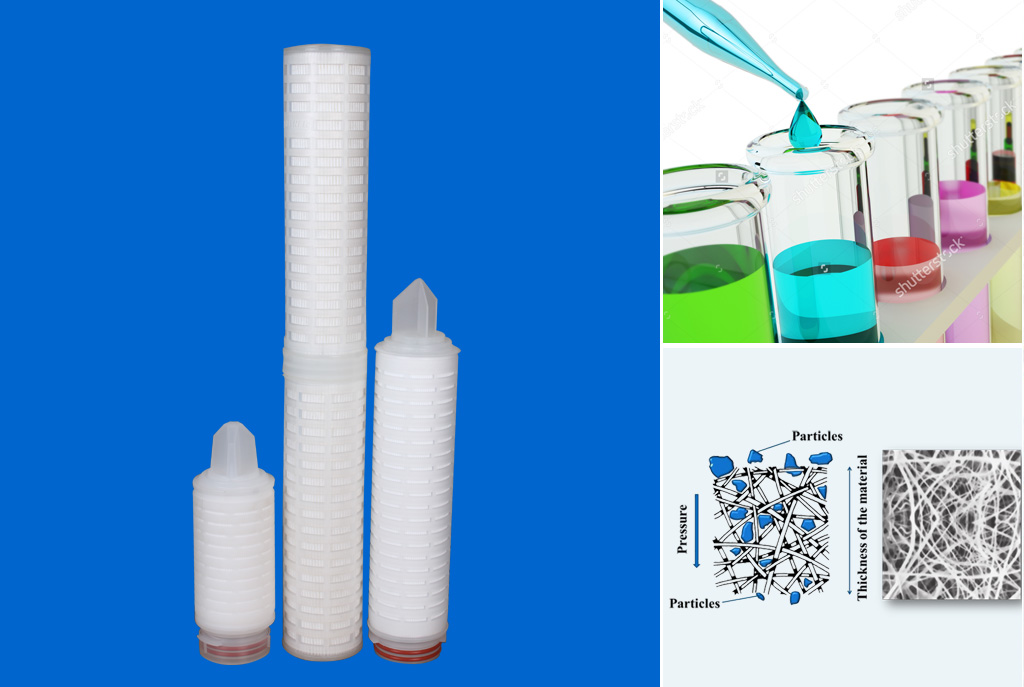

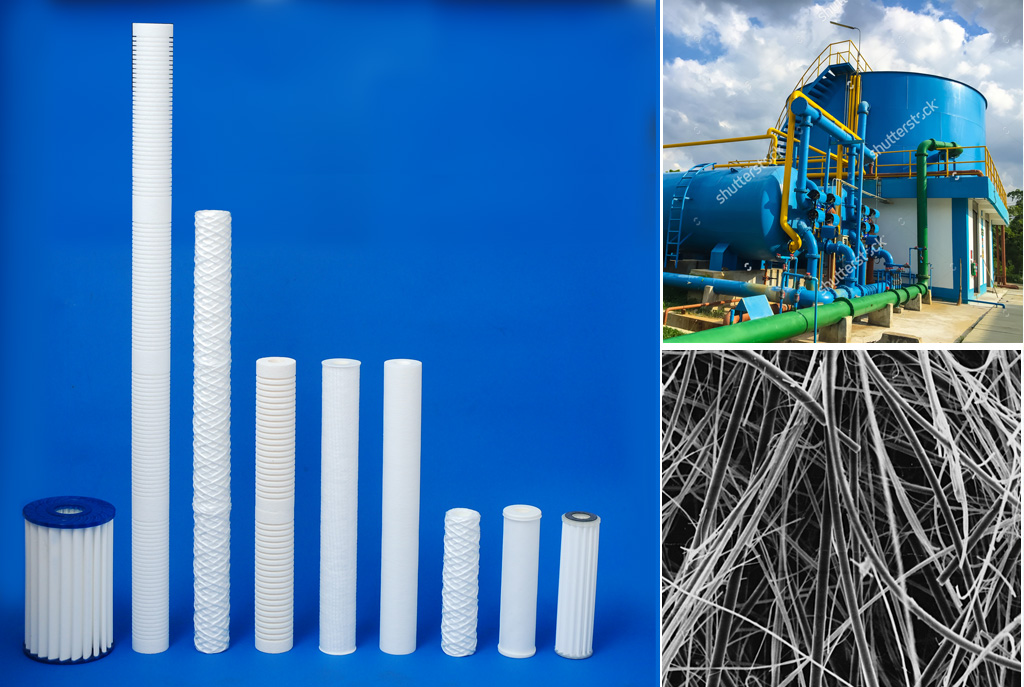

CMDF filter modules contains advanced cellulose based depth filtration media, designed to retain contaminants by both mechanical entrapment and electrokinetic adsorption. CMDF filter media is composed of high surface area filter aids embedded in a cellulose fiber matrix. The manufacturing process involves forming a filter matrix with an interconnected filtration structure with charged electro-kinetic capture mechanism. This results in porous and tortuous network capable of removing bacteria, particulate, cellular debris and submicron contaminants to a level which mechanical screening alone cannot achieve. Microfilt CMDF Module filter is available in 9 cell, 12 cell, 14 cell, 16 cell and as per customer requirement. Microfilt CMDF series filters are made for a broad field of solid liquid separation applications. The technology is designed for high service life of filter media and equipment. Its high filtration performance, top manufacturing quality and comprehensive set of certificates meet the high standards sensitive applications.