METRIT CHEMICALS P.LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to METRIT CHEMICALS P.LTD

Zinc Phosphating

Zinc phosphating is also well know as 7 tank process.

A high-quality conversion coating is essential for the durability of painted metal goods. The process of applying an inorganic conversion coating(phosphate) to a metallic surface involves removing any surface contaminants, then chemically converting the clean surface into a non-conductive, inorganic conversion coating. Conversion coatings increase the overall surface area and promote adhesion of the subsequently applied paint. In addition, conversion coatings change the chemical nature of the surface(It Forms zinc phosphate or iron phosphate) which increases corrosion resistance. It is these two functions, increasing surface area and changing the surface chemistry, that serve as a base for preparing the substrate material for paint finishes.

The process of Phosphating basically relies on the basic pickling reaction that will occur on the metal substrate if the process solution will come in contact with metal. The biggest benefit that Phosphating can give is corrosion protection and strong adhesion. Just like Phosphate Coating, the process of Phosphating is being used for steel parts.

Emulsified Degreasers

Metrite Emulsified degreaser is a phosphoric acid based water soluble emulsified, room temperature degreaser.

It contains surfactants and solvents designed to remove soil, heavy oils and carbonaceous deposits at ambient temperature. It removes toughest grease deposits and is ideal for replacement of alkaline degreasers used in seven stage phosphating of MS articles. Chemical is widely used for the pretreatment of air conditioner cabinets, control panels, refrigerators etc. And degreasing of articles before electroplating and aluminium Chromatising.

Our emulsified degreasers can also be used in process with our Descalers to remove scale of HRCA material in a very effective manner.

Higher concentration and longer immersion time may be required if contaminants to be removed are very heavy, dry oil film etc.

Chromatising

Chromatising (chromate conversion coating) Chromatising is used to chemically convert the surface of the aluminium product. This results in a thin oxide layer, what is referred to as a conversion layer, which offers protection. During the chromatising, a surface layer results which varies in colour from white to gold/brown iridescent. Chromatising is often applied as a coating pre-treatment as it provides high-quality adhesion and excellent protection against corrosion. Moreover, it is often prescribed locally for facings or for electrical conductivity.

Characteristics

- Electrical conducting coating.

- Effective protection against oxidation in the case of products applied internally in machines.

- As a result of the excellent adhesive characteristics, chromating is a suitable pre-treatment for further coating processes.

Aluminum Etching Chemical

Description / Specification of Aluminum Etching Chemical

We are involved in offering a wide range of Aluminum Etching Chemical to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Aluminum Etching Chemical. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

F.R.P. Chemical Storage Tank

Description / Specification of F.R.P. Chemical Storage Tank

We are involved in offering a wide range of F.R.P. Chemical Storage Tank to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of F.R.P. Chemical Storage Tank. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Zinc Phosphating Chemicals

Description / Specification of Zinc Phosphating Chemicals

We are involved in offering a wide range of Zinc Phosphating Chemicals to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Zinc Phosphating Chemicals. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

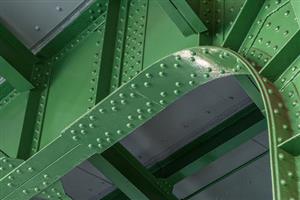

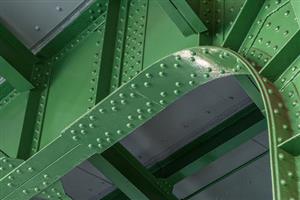

Green Chromate Coating

Green Chromate Coating For Aluminium

ASHCROM-EL - a chemical product manufactured by Ashok Industry is used for getting chromate conversion coatings on Aluminium.

Depending on Aluminium composition and process the colour obtained varies from iridescent to olive green. ASHCROM-EL has the ability to cover up scratches and other blemishes while giving a decorative finish at the same time.

Paint Remover

STRIPZOL-EPR-4 is a versatile stripper specially formulated for easy removal of epoxy based paints, coatings & markings, Its stripping action is even more rapid on ordinary paints, primers, synthetic enamels and lacquers.

STRIPZOL EPR-4 is a bi-phase stripper consisting of a catalytic phase and an active phase. The upper catalytic phase is extremely necessary to enhance the stripping action of the active phase. The upper catalytic phase prevents loss of the active phase due to evaporation. Make-up of the catalytic phase can be done by adding a little amount of water.

F.R.P. Scrubber

CHEMIKLIN-20 is an aqueous acidic mixture, soluble in varying proportions with water. It is a very effective degreaser, etcher and desmutter for Aluminium surfaces. It does all these three functions in one operation.

CHEMIKLIN-20 is used at low temperatures and low concentrations and does not give rise to scale or sludge nor does it generate fumes in working environment.

A uniform matt finish is produced over a wide concentration range with a low level of metal removal.

P.P. Pickling Tanks

Asfoclean-B manufactured by Ashok Industry is a white chemical in powder form which is used for removal of oils, soils, lubricants, cutting coolants from various type of metal surfaces. Degreasing chemicals.

A 5% - 10% solution of Asfoclean-B with water is to be prepared in a container and parts/components that are to be cleaned are immersed in this solution. Heating of this solution will accelerate the degreasing process. Asfoclean-B degreaser can be used before plating, zinc phosphating, chromating, galvanizing, etc. It is available in two Packing of 10 kgs and 50 kgs.

Ashok Industry manufactures a wide range of degreasers and cleaners since 1960 and is an ISO 9001-2008 Certified Company.

Room Temperature Alkaline Degreaser

Thelnikal LD is specially formulated to effectively remove thin oil, grease etc. Which are not of the drying type from both ferrous & non ferrous surfaces.

Thelnikal LD removes thin wet films which are not of the drying type; the oil film may have accumulated superficial dust and soils, which have settled on the surface in storage.

Spray Degreaser

THELNIKAL-SP is specially formulated to effectively remove thin oil, grease and other superficial impurities etc. which are not of the drying type from ferrous surfaces by spraying.

PARAMETER FOR SPRAY PROCESS: Concentration 20 Kgs. of chemical dissolved in water for every 1000 litre bath working volume. Dwell time 120 to 180 seconds. It works between Room Temperature to 55 deg C.

Fume Exhaust System With Scrubber

Aluminum a soft metal has to be degreased properly. Strong alkalis will etch the surface and care shouls be taken to avoid it.

THELNIKAL LD

The starting point of metal finishing is metal cleaning. Metal cleaning is the removal of undesirable soils and oils. Soil assumes many forms: machining, forming, grinding, stamping, drawing, and buffing etc. All leave behind residues superficial impurities. Oils, grease, soaps, protective oils also contaminate the surfaces

P.P. Anodizing Tanks

( Versatile Alkaline Cleaner for Aluminum surfaces by spraying )

Aluclean SP is specially formulated alkaline cleaner for cleaning and degreasing of aluminum surfaces in automotive, architectural and household usages.

After cleaning with Aluclean SP it can be taken for any further treatments.

Manganese Phosphatingchemical

(A Bio-degradable cleaner & degreaser for oxygen services)

Unlike petroleum-based solvents, aqueous cleaners such as Bioclean solutions that are typically non-flammable and contain little or no Volatile Organic Compounds (VOCs), which damage the atmosphere. Although they clean differently, aqueous cleaners perform as well as solvents. The product is designed to clean through brush at ambient and heated temperatures. But cleaning can be enhanced through spraying.

Degreasing Chemical

Application:

SCALGUN-HT can be used in Plastic or FRP/PVC lined M.S. Tank or container.

- Prepare 20% - 50% by volume of SCALGUN-HT with water

- Immerse the contaminated parts in this solution for 15-60 minutes at room temperature till parts are completely cleaned.

- Rinse with fresh running water.

- Immerse parts in 1-2% solution of COROBIT-ARP with water at room temperature at 60ºC for 2-3 minutes to neutralise and passivate the parts. Maintain the pH of this solution between 9-10.

- Dry the surface, or dip in ASFOSIL-DW for preserving and protecting them for 3-4 months.

Pickling Chemicals

Our above product is an acidic composition containing organic inhibitors and surface active agents, suitable for use as a low cost general purpose descaling and derusting chemical specially for carbon steel or hot rolled steel & for cast iron parts by dip method.

Properties & Uses :

Rust and black scale oxides and heat treatment scales are readily removed from mild steel and ferrous alloys with negligible attack on the base metal because of the inhibitor content. Metal losses are reduced to as much as 6 to 8 times than using straight hydrochloric or sulphuric acids for pickling. Thus it enables long contact times to be used without fear of high metal losses.

Derusting And Descaling Chemical

Applications:

Although RUST SOLVENT is an excellent remover of rust, surfaces having extremely heavy scales or rust formation should be removed mechanically or by means of wire brush during dipping method.

I) Diiping Method:

Concentration:

- For heavy contamination mix 1 part RUST SOLVENT with 1 part water by volume

- For medium contamination - 1 part RUST SOLVENT with 2 parts water by volume

- For light contamination - 1 part RUST SOLVENT with 3 - 5 parts water by volume

Derusting Chemical

We offer our product PEDIGREE, WHICH

- Functions at room temperature (20 deg. c)

- Removes thin, wet films of oil, grease etc;

- Removes mill scale,

- Removes certain types of heat-treatment scales, and welding scales.

- Does not leave any smut.

- But leaves the surface free from rust & mill scale.

- Does not produce fumes as a product of reaction between the chemical and the metal; but there will be slight smell, which can be sucked and blown away through hoods suitably placed above the pickling tank.

Iron Phosphating

Salient Features:

- Removes thin films of oil

- Forms a light amorphous iron phosphate coating on ferrous and steel components.

- Forms zinc phosphate coating on galvanized steel surfaces by converting a part of the zinc surface into an integral zinc phosphate coating.

- Forms aluminium phosphate coating on aluminium surfaces. The phosphate coatings so formed will be a good base for subsequent liquid painting and powder coating.

- May be used as 3-stage, or 5-stage, depending upon type and degree of oils and superficial impurities.

- My be used by dip process, or by spray process

- In spray process, dwell time is 60 to 120 seconds.

- In dip process, duration of dip is 7 to 10 minutes.

- Build-up of iron phosphate coating: 50 to 60 mg./sq.ft.

- Build-up of zinc phosphate coating on galvanized steel surfaces will be around 50 -150 mg/sq.ft.

Build-up of aluminium phosphate coating: 50 to 100 mg./sq.ft.

Zinc Phosphating Phosphate Conversion Coating

Salient Features:VANGUARD RCFunctions at temperature range of: 65 to 70 deg. C. In about 3 to 5 minutes' of dip duration, forms velvet-smooth, dense, very hard and crystalline calcium modified zinc phosphate coating. The Coating wt: between 250 and 400 mg/s.ft. It is an Ideal base for subsequent painting liquid paint, powder coating,The Calcium present acts as the in-built grain refiner in the phosphating bath and hence eliminates the need for a separate activation or a titanium pre-rinse step. Thus, the introduction of calcium not only results in the formation of coatings of good quality, but also contributes to the economy of the process through the elimination of the pre-rinse process stage

Trication Coating

ZINPOFOR-TCI gives light, smooth, dense, crystalline zinc trication phosphate coating (zinc–nickel-manganese phosphate coating), firmly adherent to, and integral with the surface being treated. the build up of the coating is around: 100 to 400 mg/s.ft. the treated surface is ideal for liquid painting and powder coating.

Manganese Phosphating

We have two products VANGUARD M & DUROPHOS M

DUROPHOS-M,Produces smooth, crystalline, highly porous, manganese-iron phosphate coatings, Build-up of coating weight: 1500 to 4000 mg/ s.ft. In a dip duration of 10 to 30 minutes, depending upon the steel surface, and the type of surface preparation. absorbs and retains oils, and sealing waxes; Provides excellent corrosion resistance, and breaking-in properties on wearing parts.

VANGUARD-M,Produces, smooth, crystalline, highly porous, manganese-iron phosphate coatings Build-up of coating weight: 700 to 1200 mg/sft. Dip duration 5 to 15 minutes, depending upon the steel surface, and the type of surface preparation. absorbs and retains oils, and sealing waxes;Provides excellent corrosion resistance, and breaking-in properties on wearing parts. Only one chemical is used for both make-up and for replenishment. Formulation of chemical includes a self-regenerating type of accelerator.

Hot Zinc Phosphating

Salient Features:

DUROPHOS-25 functions as a 3.54% solution at optimum operating temperature of 85-90 Deg. C.

DUROPHOS-25 gives heavy, absorptive zinc phosphate coating wt between 1000 and 2500 mg/sq ft, in a dip duration of 10 to 30 minutes, which may be oiled, waxed or given a coat of liquid paint for outstanding corrosion resistance.

Effluent Treatment Plant

JETTALIZER ( Hot Black Oxidizing Chemical)

Black oxide coatings are chemical conversion coatings, applied as a protective or decorative finish. Black oxide coatings have properties that make them ideal for certain applications. They are suited for moving parts or sliding surfaces that cannot tolerate the dimensional build-up of the more corrosion-resistant finishes. JETTALIZER bath operates at between 136 and 143 Degrees C.

Room Temperature Scale Removerdescaling

Koldblak functions at 20o+ C. It blackens steel and cast iron components. Cold blackening process is simple and safe to operate and produce high quality results.

Koldblak forms a copper selenide coating, which when sealed with appropriate oil, wax, etc will provide corrosion resistance to the treated components. Comes in liquid and gel form.

Phosphating Plants

ALUGOLD chromating chemical is designed to treat aluminium, and its alloys

ALUGOLD gives yellow chromate coating, giving low coating weight and higher conductivity; the corrosion resistance is very good, and provides a good adhesion base for paint film, whether it is powder coating or liquid painting.

ALUGOLD is used as a 3% solution;

Functioning at Room Temperature (25oC)

Dip duration: 3 to 5 minutes.

Surface Treatment Chemical

|

Pickling Chemical

USES :

The finish has attractive appearance combined with corrosion resistance, ability to cover up scratches and other blemishes which have occurred during the previous stages of manufacture and has resistance finger marking and capability of being spot or flame welded. It provides a satisfactory base for final paint finish and helps in increasing the life of paint considerably.

Specially for aluminium components used in the electronic industry it serves as a final finish with anti-corrosion properties.

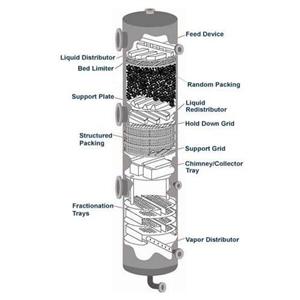

Packed Bed Scrubber

We are renowned names in the industry, offering highly durable range ofPacked Bed Scrubber that is manufactured with utmost accuracy. Our entire product range is functionally advanced in nature and ensures durable standards. We offer them in varied grades and are delivered as per the exact preferences of clients. Moreover, we offer them at most affordable rates.

Features:

- Anti corrosive

- High durability

- Cost-effective

Fume Scrubber

Description / Specification of Fume Scrubber

We are involved in offering a wide range of Fume Scrubber to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Fume Scrubber. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Packed Tower Scrubber

Quality being the prime concern, we offer our clients an extensive range ofPacked Tower Scrubber that are acclaimed among the clients for durable standards and high quality. Our entire product range is in adherence with set quality standards and is used in varied industrial applications. With the assistance f experienced and dedicated professionals, we offer an exceptional range of products.

Features:

- Timely delivery

- Competent price

- Market leading prices

Polypropylene Tanks

Applicable industries:

- Chemical process industry

- Metal refining industry

- Pharmaceutical industry

- Food processing industry

- Pulp and paper industry

- Metal finishing industry

- Fertilizer industry

- Desalination plants

- Water treatment plants

Specifications:

- Capacity: 1 KL to 300 KL

- Temp: 20 -110 oC

- MOC: PP / FRP / PVC / PVDF / FRVE

- Type: Vertical / Horizontal / Cylindrical / Rectangular

P.P Tanks

Quality being the main concern, we offer our clients an extensive range of PVDF FRP/ PP Tanks that are fabricated with utmost accuracy. Our entire product range has high tensile strength and is delivered in standard dimensions. PVDF FRP Tanks are durable in nature and have optimum compressive strength. With the assistance of experienced professionals, we are able to cater diverse requirements of the clients.

Testing facilities:

- Spark tester

- Hardness tester

- Hydro tester

- Tensile testing machine

P.P Anodizing Tanks

Features:

- 100% Leak Proof

- Designed on CAD-CAM Auto Desk

- Polypropylene tanks are designed on "RITA" Tanks Building Software module

- Radius at corner using full sheet of Thermoplastic for Pickling Tank

- Weld fewer radiuses

- Inspected and tested with Imported High Voltage tester

- Post Annealed after Welding

- Radius Bended Design

- Corrosion Proof

- Environment-friendly Fume Removal System

- Environment-friendly Design

- Thermoplastic

- Built-in Slope for easy sludge removal

- Available with pipe spreader

- Available with built in suction slit and suction lips / ducting

- Available with Connections like Drain and Overflow

- Repairable

- Reinforced and supported by mild steel frame with fiber glass covering

- Sound mechanical strength

- Solid all Plastic Tank incorporating massive load support structure

- Thermoplastic tank with Integral Heating System

- Thermoplastic Tanks are welded with state-of-the-art extrusion and Butt Fusion process

- Mechanical strength for Galvanizing heavy weight structure

- Thermoplastic Tank with integral fume collection ducting for exhaust

Polypropylene Tank

2 in 1 mcl_5 removes of wet oil and other superficial impurities from cold rolled mild steel components, cast iron surfaces, forged components, machined surfaces etc.

Removes light to medium rust and certain types of welding and heat-treatment scales.

Leaves the treated surface in a relatively passivated condition.

P.P. F.R.P. Tanks

Acidic degreasing is commonly preffered for the metal parts aslo need rust removal. Rust, scale and soot cleaning can be made by acidic type degreasers. I?? is suitable to treat various kind of metals such as aluminium, steel, iron...etc.

However acidic degreasing baths can work at ambient temperatures, Acidic degreasing is advantagous to work at higher temperatures to have more efficient degreasing and derusting. Acidic degreasing products include surfdactants, emulfifying agents, inhibitors and acids (phosphoric, sulfuric, hydrochloric, hydrofluoric acids). Treating solution has strong acidic nature, hence bath material must be made of stainless steel or PP. It must be avoided to work too high concentration of chemicals.

It is an effective acidic degreasing product including acid mixtres, enulgators, inhibitor and surfactants. Suitable for iron and steel. It can work at room temperature, at higher degrees it is more effective. Degreasing and rust removing can be done at the same time. Use concentration can be in the range of % 10 - 40 according to grease or rusting on the surface. It can be employed between degreasing bath and phosphating bath in phosphte coating lines for rust removal operation after alkaline degreasing.

Metal Treatment Chemical

Metal Treatment Chemical clean, protect and brighten all types of copper alloys, in a variety of industries, ranging from screw machine parts to decorative hardware. We have copper cleaning chemical products designed to remove a variety of soils including copper oxide/tarnish, buffing compounds and oils.

Paint Strippers

Chemical paint removers work only on certain types of finishes, and when multiple types of finishes may have been used on any particular surface, trial and error testing is typical to determine the best stripper for each application.

Solvent paint strippers penetrate the layers of paint and break the bond between the paint and the object.

Self Reinforced Polypropylene Tank

We are the dynamic, business-oriented organization, ranking among the utmost entities in manufacturing and supplying a wide range ofSelf Reinforced Polypropylene Tank that is available in various sizes. While manufacturing these tanks, we only use quality accepted material. Provided gamut is extremely used for storage purposes. Apart from this, these unmatched quality tanks are delivered within committed time frame.

Phosphating Plant

With our spacious experience and knowledge, we are occupied in offering a wide collection ofPhosphating Plant. These industrial plants are well-known in the market for their outstanding features. Enormously demanded in a vast variety of industries, these industrial plants are assembled by our experienced professionals using quality enriched innovative technology. Clients can avail these industrial plants at nominal prices.

Features:

- Maintenance free

- Application specific design

- Requires less space

Plant With Fume Exhaust System

Our vast industrial experience enables us to offer quality-proven Plant With Fume Exhaust System. Provided systems are largely demanded by our honored clients for their essential features. Identified for their quality, these systems are processed using ultra-modern technology in fulfillment with worldwide standards. Apart from this, we also offer these elevated quality system in a range of packaging options to suit the detailed information of the clients.

Features:

- Accurate composition

- High purity

- Well tested

Phosphate Conversion Coating

Being perfectly shaped and swift movement of our organization, we are instrumental in offering Phosphate Conversion Coatingchemicals for our valuable clients. Used in a wide range of industries, offered products are formulated by our experienced professionals using the best quality chemicals. To ensure the enhanced quality and purity of our offered chemicals, a team of quality controllers tests this assortment against diverse parameters.

Features:

- Accurate composition

- Excellent chemical stability

- low foaming

Room Temperatures Degreaser

Metrite-123SP is a phosphoric and based water soluble emulsified, room temperature degreaser. It contains surfactants and solvents,It is designed to remove soil, heavy oils and carbonaceous deposits at ambient temperature/It removes toughest grase deposits and is ideal for replacement of alkaline degreasers used in seven stage phosphating of MD articles. Chemical is widely used for the pretreatment of air conditioner cabinets, control panels refrigerators etc and degreasing of articles before electroplating and aluminium chromatising

Metrite123SP is used normally at 10-15% conc. V/V in water at ambient temperature with swabbing or immersion time of 5-10 minutes

High concentration and longer immersion time may be required if contaminants to be removed are very heavy, dry oil film etc

As the Chemical is highly acidic, it should be prepared in PP or FRP lined tank

Gi Sheet Pretreatment

Our organization is known in the industry for catering a distinguished range of GI Sheet Pretreatment. With the help of progressive machinery in compliance with set worldwide standards, these pretreatment chemicals are processed by our adept professionals. Offered chemical is perfect for pretreatment of zinc coated steels, galvanized sheets & zinc die casting before powder coating or liquid painting.

Electroplating Plant

With our spacious experience and knowledge, we are occupied in offering a wide collection ofElectroplating Plant. These industrial plants are well-known in the market for their outstanding features. Enormously demanded in a vast variety of industries, these industrial plants are assembled by our experienced professionals using quality enriched innovative technology. Clients can avail these industrial plants at nominal prices.

Features:

- Maintenance free

- Application specific design

- Requires less space

Paint Stripper

Unlike petroleum-based solvents, aqueous cleaners such as BIOCLEAN solutions that are typically non-flammable and contain little or no Volatile Organic Compounds (VOCs), which damage the atmosphere. They are safe and effective. Although they clean differently, aqueous cleaners perform as well as solvents. The product is designed to clean through immersion at ambient and heated temperatures. But cleaning can also be enhanced through either ultrasonic, spraying, or agitation.

P.P. Or F.R.P Vessel

Features:

- Corrosion resistant

- Light in weight

- High impact strength

- Easy to handle & install

- Maintenance free

- Superior outlook

Quality assurance:

- All vessels are warranted for workmanship over a period of one year.

- Unique serial no to each vessel for tracking the records

- Smooth external glossy finish

- UV & scratch resistant external epoxy paint

- Hydro test 1.5 times working pressure

P.P Pickling Tanks

Features:

- Polypropylene tanks are designed on "RITA" Tanks Building Software module

- Radius at corner using full sheet of Thermoplastic for Pickling Tank

- Weld less radius

- 100% Leak Proof

- Designed on CAD-CAM Auto Desk

- Radius Bended Design

- Corrosion Proof

- Environment-friendly Fume Removal System

- Inspected and tested with Imported High Voltage tester

- Post Annealed after Welding

- Environment-friendly Design

- Corrosion-free

- Thermoplastic

- Built-in Slope for easy sludge removal

- Available with Connections like Drain and Overflow

- Repairable

- Available with pipe spreader

- Available with built in suction slit and suction lips / ducting

- Reinforced and supported by mild steel frame with fiber glass covering

- Sound mechanical strength

- Solid all Plastic Tank incorporating massive load support structure

- Mechanical strength for Galvanizing heavy weight structure

- Thermoplastic Tank with integral fume collection ducting for exhaust

- Thermoplastic tank with Integral Heating System

- Thermoplastic Tanks are welded with state-of-the-art extrusion and Butt Fusion process

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.