METDERM TREAT

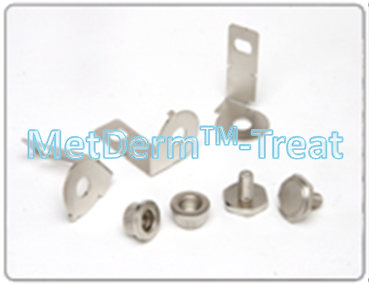

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to METDERM TREAT

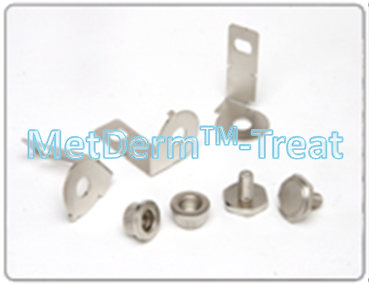

Electroless Nickel (E.N) Plating

Plating 68492.jpg)

Electroless Nickel (EN) coatings are today one of the fastest growing and most widely used coating in metal finishing industry. Coating imparts harness, corrosion resistance etc. subject to the specified chemistry. Due to auto catalytic reaction, deposition is uniform irrespective to the geometry of an object. This property eliminates problems normally associated with electroplating; post-plating operations like machining or polishing are often avoided.

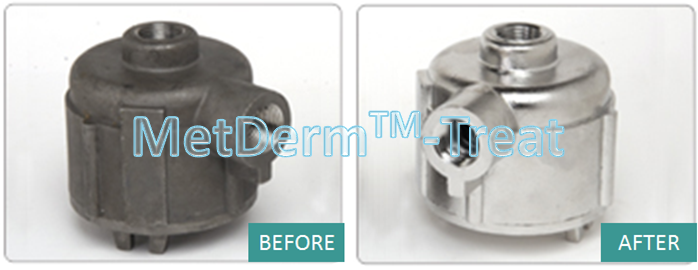

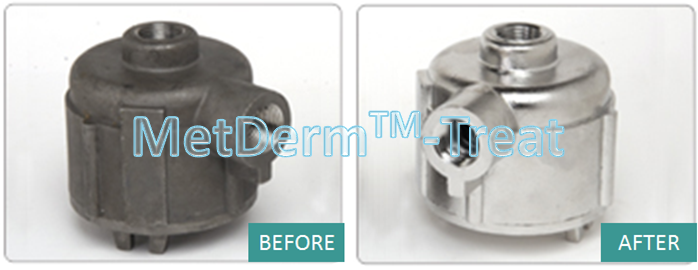

Electro Polishing

Advantages

The process creates microscopically smooth surface that is highly reflective with bright finish.

It removes particles / contaminants embedded from the previous mechanical operations.

Process promotes uniform and protective oxide layer.

This drastically improves corrosion resistance.

During the process, de-burring and polishing is simultaneous.

Nickel Sulphamate Plating

Nickel Sulfamate plating is a 99.99% pure and electrolytically deposited and offers excellent corrosion resistance along with high tensile stress and ductility without stress cracking / deformation. Coating prevents fretting / galling with less porosity than most of the electrolytic deposit.

Hard Chrome Plating

Advantages

- The deposit offers excellent non-stick lubricity.

- Due to low wear rate, the deposit is preferred under high stress contact against sand, coal, cement, glass etc.

- Since the deposition temperature is low, problems like material distortion observed in the hardening process can be avoided.

- Deposit provides excellent corrosion resistance to most of the acids/alkali.

- Deposit can be machined.

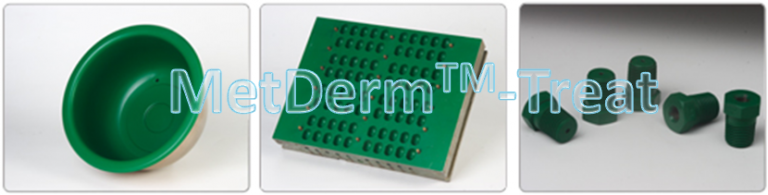

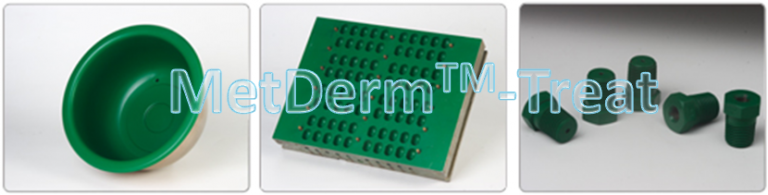

Xylan Coating

Xylan (Teflon) gives a non-metallic coating on metallic surface. This film is made of a chemically resistant group material (PTFE / FEP / PFA). Xylan film is smooth, offering very low coefficient of friction and good abrasion resistance. The Coating has very good non-stick property and internal lubrication. Temperature tolerance of this coating is about 250°C.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

Plating 68492.jpg)