METAL PLANTS INDIA P.LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to METAL PLANTS INDIA P.LTD

Reactors

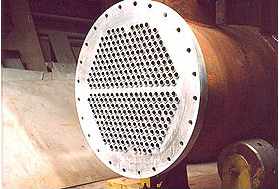

METAL PLANTS designs, engineers and manufactures customizedReactors, Kettles and Agitated Vessels for blending, dissolving, reacting or in some instances a combination thereof. The dimensions & operating conditions will be as per Customer’s requirements. The Equipment can be fitted with propeller, turbine, paddle, helical or anchor type agitator. For high viscosity products, double action agitator arrangement can also be supplied.

METAL PLANTS agitators are designed based upon individual process conditions and the degree of agitation to achieve product quality of desired characteristics. The construction of agitators is effected, wherever possible, using commercially available components such as motors, couplings, reducers & shaft seals etc so as to increase the availability of spares in local market in case of emergency.

METAL PLANTS fabricates equipments from Standard & Low alloy carbon steel, Austenitic Stainless Steel and other alloy steels, in either solid or clad construction depending on process requirements with view of cost considerations. The equipments are normally offered under standard QAP Inspection Plan or under Third Party Inspection, as necessary.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.