MECHELONIC WELDERS P.LTD. M

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MECHELONIC WELDERS P.LTD. M

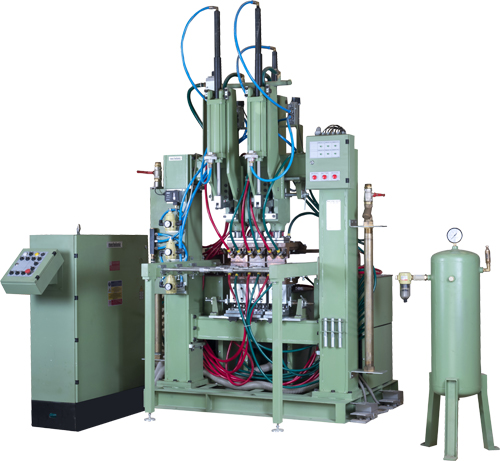

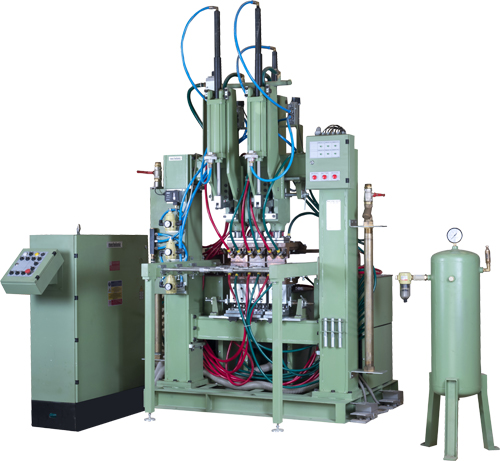

Press Type Welders

The Mechelonic Press-type welders are designed for high-speed production work to meet the needs of a vast number of industry applications. The mechelonic press-type pneumatically operated pedestal spot/projection welders are available in different styles of welding head arrangements.

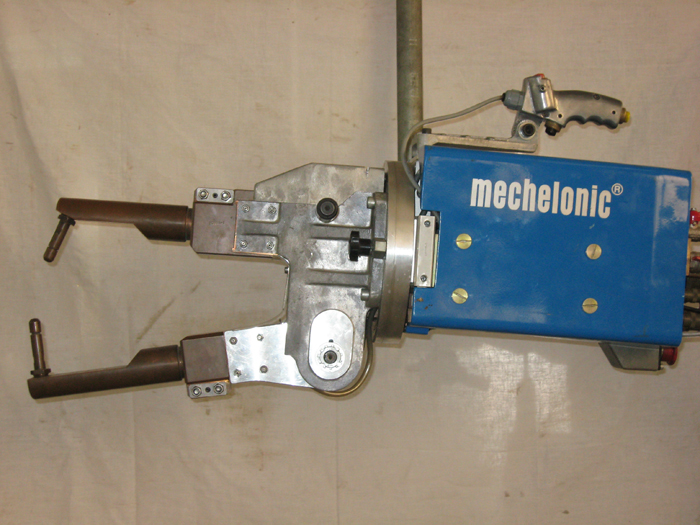

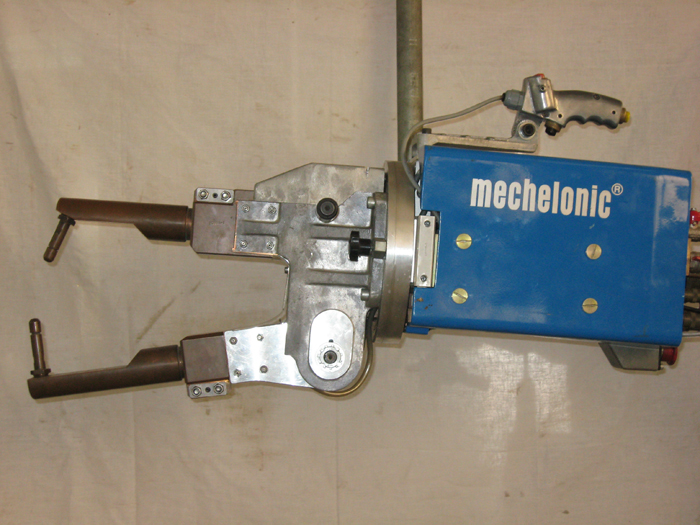

Portable Welder Transgun

Mechelonic offers a range of Transguns for continuous heavy-duty spot welding to support high-speed production. Portable Welding stations are used to weld large objects in difficult to access places. The Transgun reaches a variety of geometric shapes and sizes in an easy to handle way. Tranguns in “X” or “C” type are available to suit any welding requirement.

Bench Welders

[1 KVA-50 KVA] Mechelonic Bench Welders are a economical solution for Resistance Welding of small components. The Bench mounted machines are high precision welding of small components in the electro-mechanical industry. The mechelonic Bench Welders are offered along with precision component holding fixtures and tooling ( manual or automatic). Single-phase AC and Mid-frequency options are available.

Seam Welder

The Mechelonic Seam welding machines are precision built and of robust construction suitable for a long and trouble free production. It is used for leak tight assemblies for petrol tank, shock absorbers, oil barrels and shells of can, etc. The seam welders are available for longitudinal, horizontal and universal welding requirements.

Special Purpose Machines

Mechelonic has a proven track record of providing Special Purpose Welding Machines. Our Design Team is experienced and capable of providing an engineering concept to invent the optimal Machine Tool to meet the Customer’s objective. The foundation of our Design Approach is careful attention to details such as: System reliability, Efficiency, and consistent productivity.

Welding Controls

The mechelonic welding controls state-of-the-art micro-processor based controllers. They are factory-calibrated, versatile and are suited for Spot Welding, Projection Welding, Seam Welding and Special Welding Machines involving PLC based automation and/or PC based Data-acquisition requirements. These controllers are “field-proven” and in-house developed for more than 40 years. Thousands of these controllers are in use in India and abroad.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.