MAZDA LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MAZDA LTD.

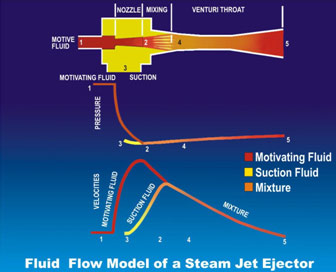

Steam Jet Air Ejector S.J.A.E. System

Description / Specification of Steam Jet Air Ejector S.J.A.E. System

We are involved in offering a wide range of Steam Jet Air Ejector S.J.A.E. System to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Steam Jet Air Ejector S.J.A.E. System. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Turbine Vacuum System

Description / Specification of Turbine Vacuum System

We are involved in offering a wide range of Turbine Vacuum System to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Turbine Vacuum System. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Combination Vacuum System Of Steam Jet Ejector And Liquid Ring Vacuum Pump

Description / Specification of Combination Vacuum System Of Steam Jet Ejector And Liquid Ring Vacuum Pump

We are involved in offering a wide range of Combination Vacuum System Of Steam Jet Ejector And Liquid Ring Vacuum Pump to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Combination Vacuum System Of Steam Jet Ejector And Liquid Ring Vacuum Pump. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Steam Jet Booster And Ejector

Description / Specification of Steam Jet Booster And Ejector

We are involved in offering a wide range of Steam Jet Booster And Ejector to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Steam Jet Booster And Ejector. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Thermocompressor

Several major plants world over have opted for Mazda’s thermocompressor technology. Due to our high number of installations we are now rated the world’s fourth largest manufacturer with steam test facilities for Thermocompressors implementing internationally adopted performance test codes.

Chiller Vactor System

No hazardous refrigerant required.

Can cool liquid to 0◦C actually could freeze, if allowed.

Are able to operate at off design conditions, i.e…. higher inlet temperature with higher outer termperature.

Controls allow for steam savings for reduced cold water flow and cold condenser water.

Not susceptible to corrosive conditions , as are other types.

Total absence of moving parts and therefore very low maintenance.

Low turn-down of load.

Very Reliable

Air Jet Ejectors

Since the pump handles 77 #/hr air at its (unchanged) suction pressure, the AAE will use 68.5 #/hr of atmospheric motive air and draw the new system suction of of 8.5 #/hr. air.

The new system suction flow is therefore 143 ACFM (10 torr suction).

Simplicity of design, operation and maintenance – no moving parts.

Availability in a wide range of materials. Standard material is cast iron with a stainless steel nozzle, but plastics , stainless steel and high alloy steel are all easily manufactured.

The Atmospheric Air Ejector is the most economical vacuum- producing device available.

Feed Water Heater

Mazda Feed water heaters are designed for specific thermal conditions and manufactured for a singular purpose. Whether it be sophisticated designs involving extreme superheat, abnormal flow conditions or dissipation of high energy fluids. In addition , Mazda provides innovative and practical concepts to ensure peak heater performance from installation to testing through full or part-load operation.

Surface Condenser

Our condensers feature high overall heat transfer coefficients (which result in smaller heat transfer areas and thus optimal use of the available space) and extremely lo oxygen concentrations in the condensate. They are designed to stand up to turbine and steam generator overloads and to variations in cooling water temperature at different times of the year.

Liquid Ring Vacuum Pumps

Ambient air at atmospheric pressure is drawn in through motive air inlet (A) and passed through a converging diverging nozzle (B). The high velocity air leaving the nozzle entrains the gases or vapors to be handled at the suction inlet (C ) and compresses this load through the Venturi (D) to the inlet pressure of the liquid ring vacuum pump. The pump then compresses the motive air and process gas to atmospheric pressure .

Hotshot Mechanical Automatic Pumps

Advantages of Mechanical Pumps

On hot condensate applications, mechanical pumps have numerous advantages against electrical Pumps.

No cavitation : There is no mechanical work ,the pressure is given by a motive fluid.

NPSH is not needed : The required distance between the receiver and the pump is maximum 300 mm.

Low maintenance costs : Cavitation does not occur that is why parts service life is much longer.

System can be closed: Save energy by using all the heat content of steam. Mechanical pumps can even work on vacuum.

Energy efficient: Do not use electrical energy Receiver size is smaller. (condensate accumulation is not needed,).

Non-electrical equipment : can be used in explosive areas, lower installation costs.

Pump handles hot condensate : as cavitation does not occur, condensate can be close to saturation temperature (more that the 99◦C limit of electrical pumps). Higher condensate temperature decreases solubility of non-condensable gases.

Heat Exchanger

Description / Specification of Heat Exchanger

We are involved in offering a wide range of Heat Exchanger to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Heat Exchanger. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Falling Rising Film Evaporators

Mazda Evaporator Technology offers custom built solutions covering every possible aspect of the concentration of industrial fluids With a vast process experience, expertise in Design, Engineering and Process Integration, unparelleled fabrication facilities and a state of art Pilot Plant, Mazda offers Evaporation Plants with the most optimal operating cost vis-a-vis initial investment.

Combination Type Evaporators

Combination Type Evaporators

Mazda offers combination of Film & Forced Circulation Evaporator Systems,specially designed for Effluent volume reduction and “Zero Effluent Discharge”.

Advantages

Ideal for effluents with high TDS, BOD,COD, toxic metals

Effluent Volume Reduction upto 95%

Manufacturing Facilities

To ensure the quality of Equipment manufactured and to meet the delivery schedules,Mazda has set up a state of art Manufacturing facility exclusively for Evaporators at Ahmedabad using the latest production techniques

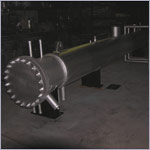

Jet Venturi Fume Scrubbers

Mazda Jet Venturi Scrubber is a dependable device designed to entrain and scrub large volumes of gases without the use of complicated baffles or moving parts.

The motivating fluid , generally water, leaves the nozzle in a hollow cone spray, creating a draft which draws the gases and vapors into the moving stream where they are continuously scrubbed / absorbed while subsequent separation is accomplished in units specifically designed to us to meet the state pollution control requirement.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.