MAYURESH ENGINEERS AND FABRICATORS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MAYURESH ENGINEERS AND FABRICATORS

Portable Type Crack Detectors

MAGNO - MASTER 1500 has been specially designed for use as a portable unit. It is normally supplied for table mounting and can be lifted by handle by one man. The accessories are contained in a sturdy canvas bag. A special box type trolley with locking arrangement for accessories is available as an optional accessory. A pram type trolley for easy maneouvrability is also available. The equipment is suitable for detecting all surface and sub - surface cracks upto a depth of 6 mm in ferro - magnetic objects of any shape and size. Demagnetisation is achieved by the suitable diameter. Facility for remote control operation has been provided.

Mobile Type Crack Detectors

[Mobile Type Crack Detectors]

[Request A Quote]

MAGNO - VAN - 2500 WG has been specially designed for use as a mobile unit. It is mounted on a wagon with two sturdy rubber wheel and a V rest. The equipment is easily pushed around and manoeuvred into desired position by one person. The equipment is suitable for detecting all surface cracks and sub - surface cracks upto a depth of 6 mm in ferromagnetic objects of any shape and size. Demagnetisation is achieved by coil or prod method. Facility for remote control operation has been provided. Mobile units with outputs upto 6000 Amps are in our regular line of production

Oil Type Crack Detectors Crack Detection Automation

Stationary unit of contact and coil type in the medium range Output of 2500 Amp in 6 steps for longitudinal magnetisation. Suitable for detection of surface and near surface crecks in ferro-magnetic components upto 1000 mm long. 80 mm dia and 50 k weight. Facility for combined magnetisation by simultaneous application of circular and longitudinal fields provided. Dark room an integral part of the unit. Demagnetisation by separate demagnetiser. HWDC facility for detection of sub-surface cracks and inclusions provided optionally.

Yoke Type Crack Detectors Crack Detection

Stationary unit of contact and yoke type in the medium range. Output of 2500 Amp Ac in 6 steps for circular magnetisation and 15 kilo Ampere Turns DC in 6 steps for longitudinal magnetisation. .Suitable for detection of surface and near surface cracks in ferromagnetic components upto 600 mm long. 80 mm dia and 50 kg weight. Facility for combined magnatisation by simultaneous application of circular and longitudinal field provided. Dark room an integral part of the unit. Demagnetisation by separate damagnetiser. HWDC facility for detection of sub-surface cracks and inclusions provided optionally.

Demagnetisers

The demagnetiser comprises of a coil through which AC at mains frequency is passed. The job to be demagnetised is pulled out of the coil along its longitudinal axis and kept at a distance beyond 1 mtr from the coil. Two versions of the coil DM 200 and DM 300 with round port of 200 and 300 mm respectively are in our current line of production, for safety MCB provided. The coils work of 230V AC, 50 Cycle, Single phase supply and give very satisfactory results.

Bar Testing Machines

This SPM is with Spring grip facility and used for testing surface as well as subsurface defects or cracks in bar. This machine is also available with coil type for longitudinal Magnetisation for checking circular cracks and circular Magnetisation fir lognitudinal cracks. This is provided with Spring grips where compressed air is not available.

Inline Crack Detection

A special purpose machine designed for detection of all surface and sub surface cracks. This machine is specially designed for in line crack detection. In this finished or semi finished products are kept on indexing table and automatically get magnetised one by one. After cycle start operation through PLC control. Two types of mag is provided, CIR as well as longitudal and also COMB facility and auto/manual mode is provided.

Universal Type Crack Detectors Crack Detection

ONE MACHINE WITH MULTI - PURPOSE USE FOR ROW MATERIAL TO FINISH JOBS. CIRCULAR - MAGNETISATION ( Head shot ) or Prod. LONGITUDINAL - MAGNETISATION with COIL technique.Capacity of coil diameter 200 mm COIL portal dia.200 mm with 6 step variable control switch. Magnetisation time control by timer with Trigger / Foot / Remote operation switch. Dark room facility with Rexene cover and curtains with folding arrangement. U. V. Tube light or BULB facility for inspection hair line and fine cracks. Circulation system for wet magnetic bath with tank and pump. Job clamping facility with spring loaded stock with 5 Kgs. pressure.

Crack Detector For Crank Shaft (Crack Detection Spm)

59704.jpg)

Description / Specification of Crack Detector For Crank Shaft (Crack Detection Spm)

We are involved in offering a wide range of Crack Detector For Crank Shaft (Crack Detection Spm) to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Crack Detector For Crank Shaft (Crack Detection Spm). Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Crack Detector For Strub Axle Spm For Crack Detection Automation

Description / Specification of Crack Detector For Strub Axle Spm For Crack Detection Automation

We are involved in offering a wide range of Crack Detector For Strub Axle Spm For Crack Detection Automation to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Crack Detector For Strub Axle Spm For Crack Detection Automation. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Crack Detector For Axle Beam (Crack Detection Spm)

59706.jpg)

Description / Specification of Crack Detector For Axle Beam (Crack Detection Spm)

We are involved in offering a wide range of Crack Detector For Axle Beam (Crack Detection Spm) to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Crack Detector For Axle Beam (Crack Detection Spm). Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Crack Detector For Valves Spm For Crack Detection Automation

Description / Specification of Crack Detector For Valves Spm For Crack Detection Automation

We are involved in offering a wide range of Crack Detector For Valves Spm For Crack Detection Automation to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Crack Detector For Valves Spm For Crack Detection Automation. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Crack Detector For Seamless Tubes Spm For Crack Detection Automation

Description / Specification of Crack Detector For Seamless Tubes Spm For Crack Detection Automation

We are involved in offering a wide range of Crack Detector For Seamless Tubes Spm For Crack Detection Automation to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Crack Detector For Seamless Tubes Spm For Crack Detection Automation. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Belt Conveyors

BELT CONVEYORS

Product is conveyed directly on the belt so both regular and irregular shaped objects, large or small, light and heavy, can be transported successfully. Belt conveyors can be used to transport product in a straight line or through changes in elevation or direction. In certain applications they can also be used for static accumulation or cartons. Belt conveyors are of basically two types, Slider bed and roller bed. Slider bed belt conveyors are generally used for light & medium light applications. Roller bed belt conveyors are used for medium & heavy applications.

Working width will range from 50 mm to 1500 mm.

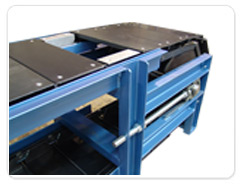

Roller Conveyors

Description / Specification of Roller Conveyors

We are involved in offering a wide range of Roller Conveyors to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Roller Conveyors. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Slat Chain Conveyors Slat Conveyor Systems

The Slat Conveyor Systems are used for general assembly production. The systems require no lubrication and very low maintenance. Slats are connected on two standards of chain by attachments. The construction is such that any slat can be removed easily. Fixtures can be mounted on the Slat for application such as assembly line conveyor. For inclined applications. Slat chain conveyor are widely used in all types of industries due to the modularity offered by its construction.

Link Belt Conveyors

Description / Specification of Link Belt Conveyors

We are involved in offering a wide range of Link Belt Conveyors to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Link Belt Conveyors. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Chain Conveyors

Chain conveyors utilize a powered continuous chain arrangement, carrying a series of single pendants. The chain arrangement is driven by a motor, and the material suspended on the pendants is conveyed. Depending upon the process the conveyors are used along with support systems like cross transfer units, lifters and stoppers. Concept of modular design is used for flexibility in all the conveyors. This conveyor is cost effective option compared to slat chain conveyors or even belt conveyors. Chain Conveyors are generally used for conveying bulk items such as cartons, pallets, bags etc.

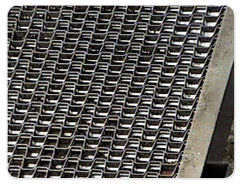

Wire Mesh Conveyors

WIRE MESH CONVEYORS

Wire mesh conveyor belts are suitable for any application like, including closed wire mesh belts for flexibility and conveying small parts, belts which having large opening for easy flow of water or air and for cleaning of your products and smooth surface belts for easy and accurate transfer. Wire mesh conveyor belts are used to convey metal parts through copper and aluminum brazing furnace, chemical product

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.