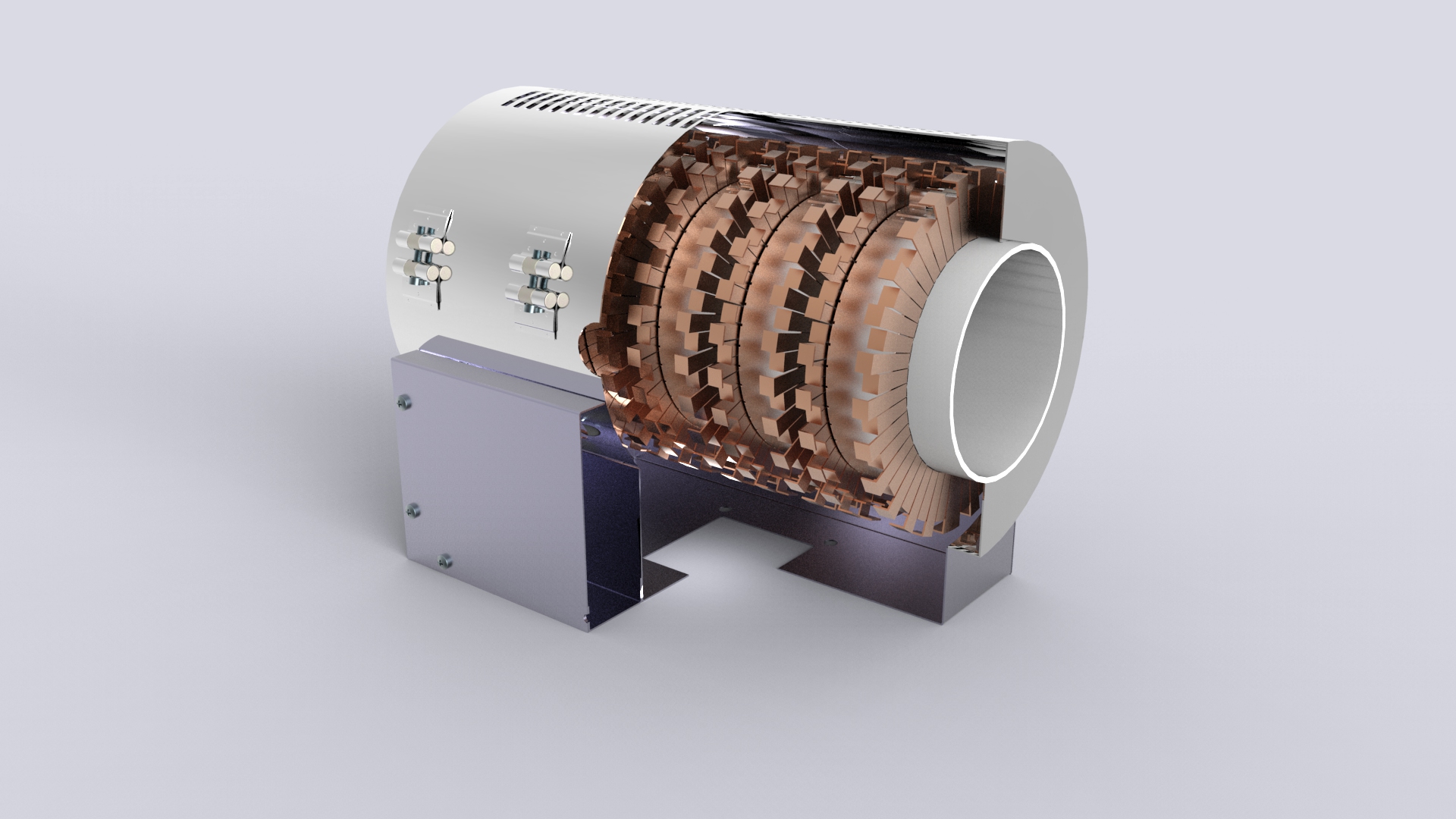

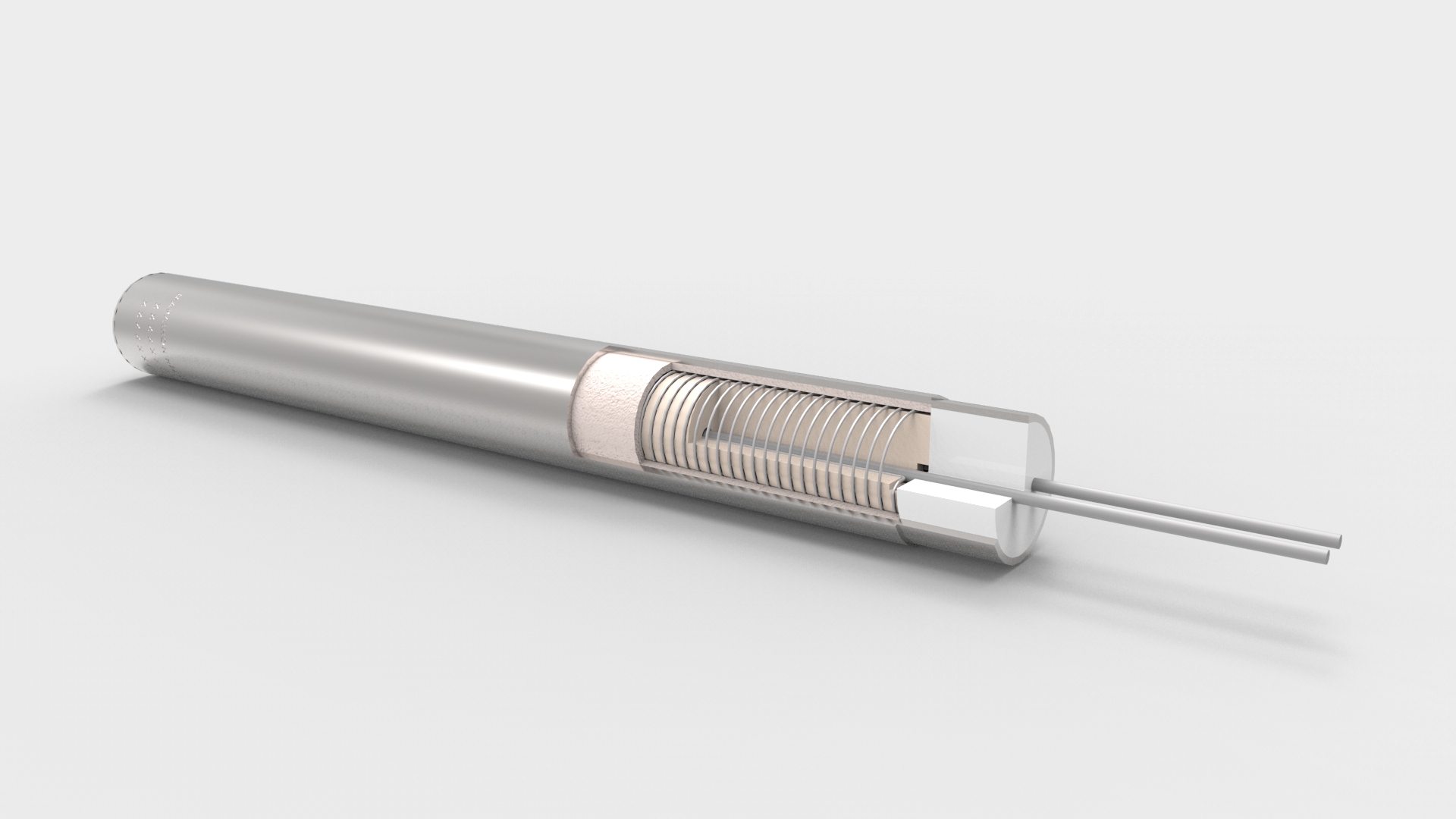

Cartridge Heater

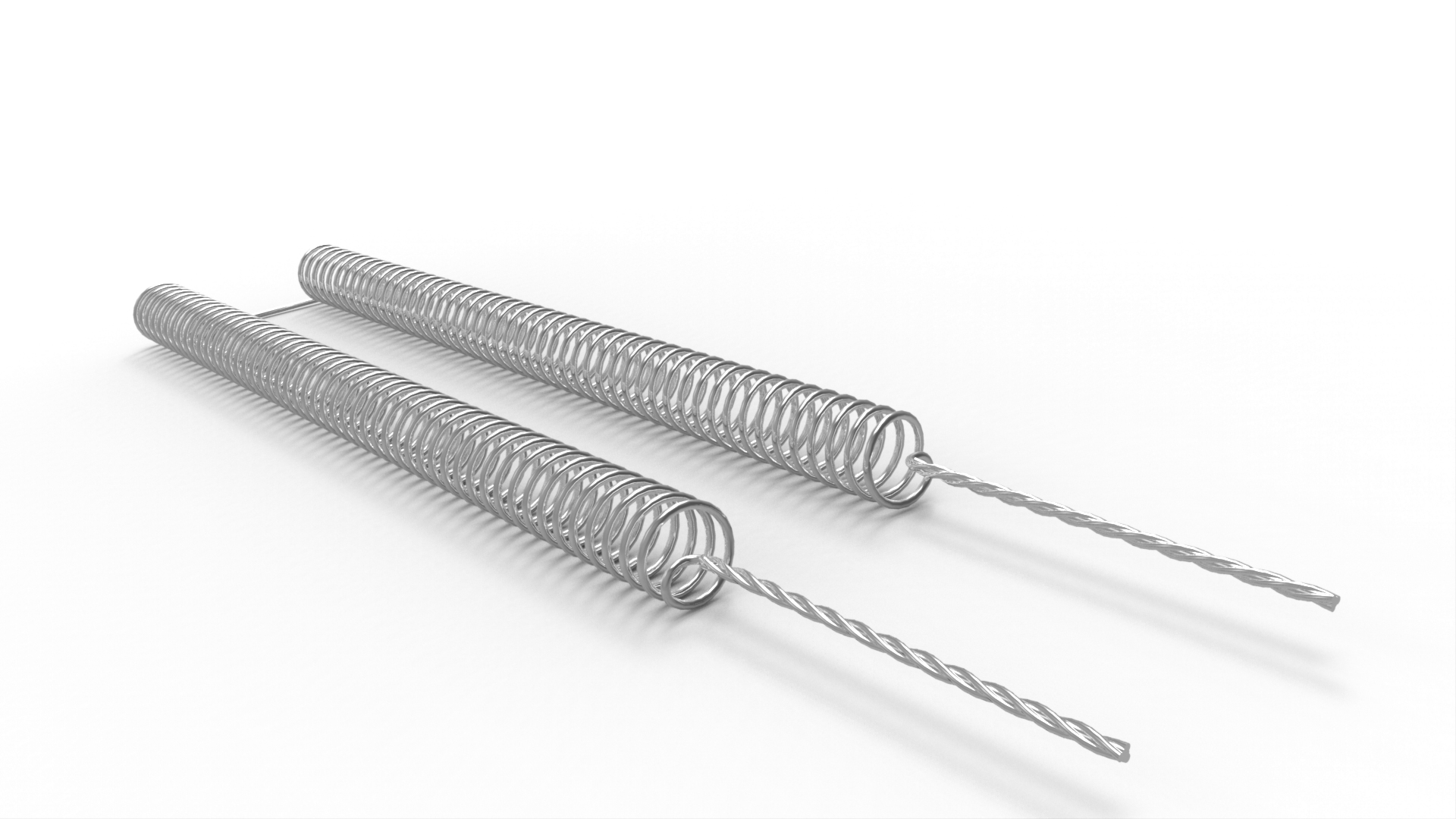

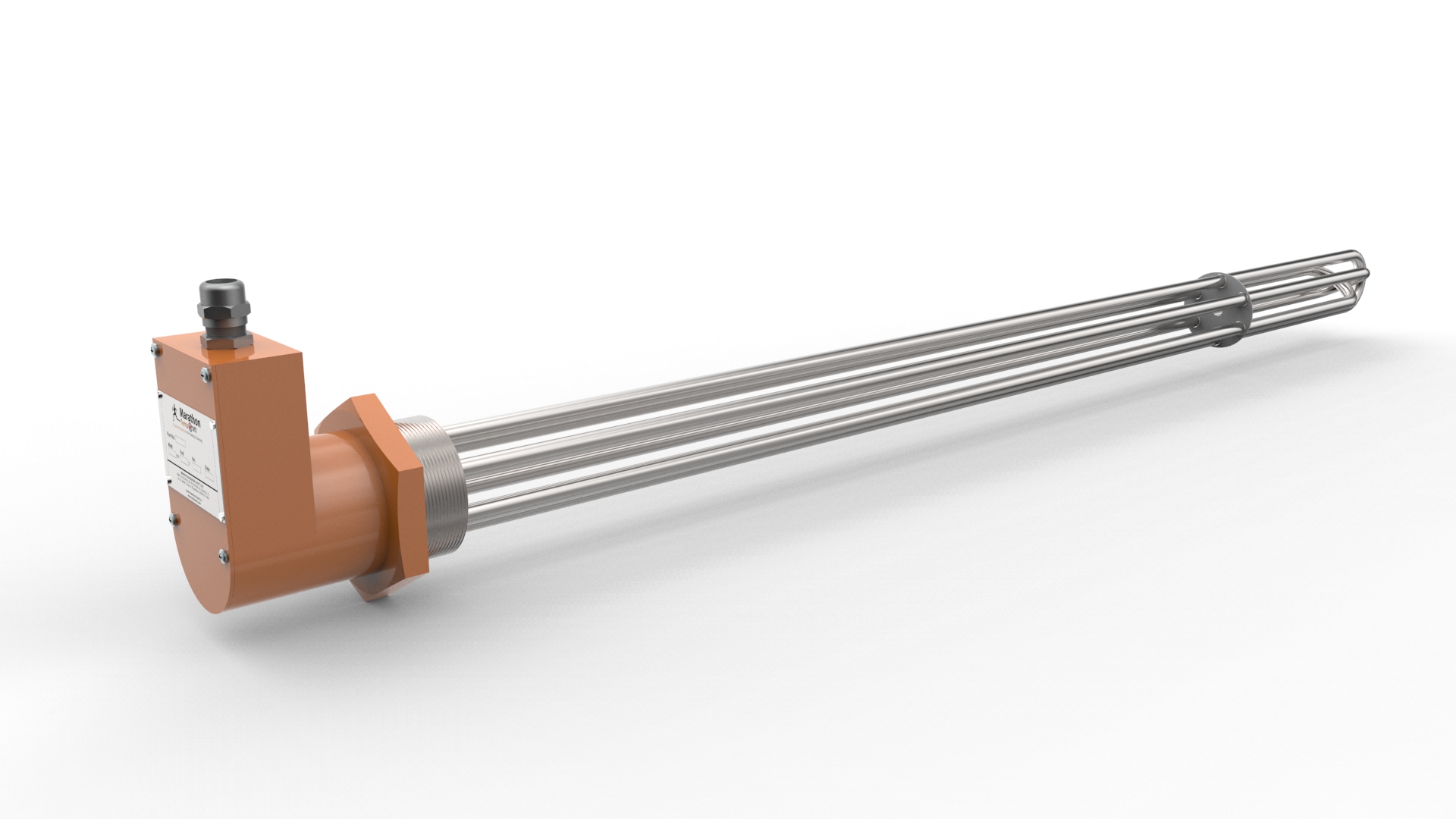

Cartridge heater often considered as component heater has a heating coil wound on a ceramic core and are cylindrical-shaped, heavy-duty Joule heating element. Electricity flows through coil when a two or three-phase voltage is applied. The electricity heats the coil and, subsequently, the cartridge sheath. The watt density (in Watt/inch2) depends on the number of spirals or turns per inch. The sheath comes in contact with the surface being heated. Insulation in the cartridge heater ensures that the heating wire never comes in contact with the sheath and protects the sheath from melting in case of any mishap. The leads that come out of the heater terminal have metal conduit, or silicon sleeves to protect from high temperature. Lead wires are often fiberglass or silicon rubber.