MANHAR METAL SUPPLY CORPORATION

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MANHAR METAL SUPPLY CORPORATION

Titanium

Titanium Grades:-Manhar Metal Supply Corporation Supplies Titanium In Different Grades. We Have Titanium Grade 1, Grade 2, Grade 5, Grade 7, Grade 9, And Grade 12.

Titanium And Its Alloys Have Proven To Be Technically Superior And Cost-Effective Materials Of Construction For A Wide Variety Of Aerospace, Industrial,Surgical Implants, Gold Refinery , Anodising Plants , Heater For Industrial Use , Marine And Commercial Applications. In North America,Approximately 70% Of The Titanium Consumed Is Utilized For Aerospace Applications.Due To The Expansion Of Existing Applications And The Development Of New Uses, The Greatest Growth Will Occur In The Industrial, Marine And Commercial Sectors

Titanium is as strong as steel but much less density. It is therefore important as an alloying agent with many metals including aluminium, molybdenum and iron. These alloys are mainly used in aircraft, spacecraft and missiles because of their low density and ability to withstand extremes of temperature. They are also used in golf clubs, laptops, bicycles and crutches.

Power plant condensers use titanium pipes because of their resistance to corrosion. Because titanium has excellent resistance to corrosion in seawater, it is used in desalination plants and to protect the hulls of ships, submarines and other structures exposed to seawater.

Titanium metal connects well with bone, so it has found surgical applications such as in joint replacements (especially hip joints) and tooth implants.

The largest use of titanium is in the form of titanium(IV) oxide. It is extensively used as a pigment in house paint, artists’ paint, plastics, enamels and paper. It is a bright white pigment with excellent covering power. It is also a good reflector of infrared radiation and so is used in solar observatories where heat causes poor visibility.

Titanium (IV) oxide is used in sunscreens because it prevents UV light from reaching the skin. Nanoparticles of titanium (IV) oxide appear invisible when applied to the skin.

The Properties And Characteristics Of Titanium Which Are Important To Design Engineers In A Broad Spectrum Of Industries Are:

Excellent Corrosion Resistance: Titanium Is Immune To Corrosive Attack By Salt Water Or Marine Atmosphere. It Also Exhibits Exceptional Resistance To A Broad Range Of Acids , Alkalis, Natural Waters And Industrial Chemicals.

Superior Erosion Resistance: Titanium Offers Superior Resistance To Corrosion, Cavitation Or Impingemnet Aatack. Titanium Is Atleast 20 Times More Erosion Resistance Than Copper Nickel Alloys

High Heat Transfer Efficiency: Under”In Service” Conditions, The Heat Transfer Properties Of Titanium Approximate Those Of Admirately Brass And Copper Nickel.There Are Several Reasons For This: 1) Titanium’s Higher Strength Permits The Use For Thinner Walled Equipment. 2) There Appears To Be Unusual And Benefical Characteristics In Titanium’s Inherent Oxide Film. 3) The Relative Absence Of Corrosion In Media Where Titanium Is Generally Used Leaves The Surface Bright And Smooth For Improved Lamellar Flow. 4) Titanuim’s Excellent Erosion-Corrosion Resistance Permits Significantly Higher Operating Velocities.

Superior Strength to weight Ratios

The Densities Of Titanium-Based Alloys Range Between 160 Lb/In3(4.43gm/Cm3) And 175lb/In3(4.85 Gm/Cm3).Yield Strengths Range From 25,000 Psi(172 Mpa )Commercially Pure(Cp) Grade 1 To Above 200,000 Psi (1380 Mpa) For Heat Threated Beta Alloys.The Combination Of High Strength And Low Density Results In Exceptionally Favorable Strength-To-Weigth Ratios For Titanium Based Alloys.These Ratios For Titanium Based Alloys Are Superior To Almost All Other Metals And Become Important In Such Diverse Applications As Deepwell Tube Strings In The Petroleum Industry And Surgical Implants In The Medical Field.

Special Information For Fraction of Titanium

Keeps tools Sharp

Titanium Has A Tendency To Gall, And Its Chips Can Weld To The Cutting Edged Of The Tool. This Is Particularly So Once Tool Wear Begins.Sharp Tools Should E Employed At All Times And Should Be Replaced Before They Dull. The Feed Should Not Be Stopped While The Tool And Work Piece Are In Moving Contact.

Grinding Of Titanium

In Grinding,The Difference Between Titanium And Other Metals Is The Activity Of Titanium At High Temperatures.At The Localized Points Of Wheel Contact Titanium Can React Chemically With The Wheel Material.The Most Important Facts To Consider In Order To Prevent This And Ensure Successful Grinding.

Joining Of Titanium

Titanium And Titanium Alloys Can Be Readily Joined By Normal Mechanical Fastener Techniques.With The Exception Of Brazing And Friction Welding,These Methods Are The Only Satisfactory Means Of Making Joints Between Two Nonweldable Titanium Alloys Or Between Titanium And Dissimilar Materials.

Hints For making Titanium

Titanium Can Be Fabricated Using Techniques Which Are No More Difficult Than Those Used To Machine Type 316 Stainless Steel.Commercially Pure Grades Of Titanium With Tensile Strengths Of 35,000 To 80,000 Psi Machine Fabricate For Easier Than The Aircraft I.E. 6al-4v With Tensile Strenghts Up To 200,000 Psi.

Welding Titanium

In General,Welding Of Titanium And Its Alloys Can Be Readily Performed, But It Is Necessary To Exclusive Reactive Gases,Including Oxygen And Nitrogen From The Air,And To Maintain Cleanliness.Thus Weld Properties Are Heavily Influenced By Welding Procedured, Especially By The Adequacy Of Insert Gas Shielding.

Fire Prevension

Storage Of Coarse Titanium Turnings And Chips Is Relatively Safe. Storage Or Accumulation Of Titanium Fines Constitues A Fire Hazard.Clean Machines And Good Workshop Practice Are Usually Sufficient To Avoid Any Danger Of Fire When Machining Titanium.

Application

Titanium Is Used In Steel As An Alloying Element (Ferro) To Reduce Grain Size And As A Deoxidizer, And In Stainless Steel To Reduce Carbon Content. Titanium Is Often Alloyed With Aluminium (To Refine Grain Size), Vanadium, Copper (To Harden), Iron, Manganese, Molybdenum, And With Other Metals. Applications For Titanium Mill Products (Sheet, Plate, Bar, Wire, Forgings, Castings) Can Be Found In Industrial, Aerospace, Recreational, And Emerging Markets. Powdered Titanium Is Used In Pyrotechnics As A Source Of Bright-Burning Particles.

Industrial

Welded Titanium Pipe And Process Equipment (Heat Exchangers, Tanks, Process Vessels, Valves) Are Used In The Chemical And Petrochemical Industries Primarily For Corrosion Resistance. Specific Alloys Are Used In Down Hole And Nickel Hydrometallurgy Applications Due To Their High Strength (E. G.: Titanium Beta C Alloy), Corrosion Resistance, Or Combination Of Both. The Pulp And Paper Industry Uses Titanium In Process Equipment Exposed To Corrosive Media Such As Sodium Hypochlorite Or Wet Chlorine Gas .Other Applications Include: Ultrasonic Welding Wave , Wave Soldering, And Sputtering Targets. Titanium tetrachloride a colorless liquid, is important as an intermediate in the process of making and is also used to produce the Ziegler-Natta catalyst.

Titanium Tank

|

Titanium Tank For Gold Refinery

|

Titanium Tank For Chemical Process

|

Titanium Pan

|

Titanium Cooling Coil

|

Titanium Crucibal

|

Tantalum Pipes And Tubes

Standard:

As per ASTM B521-98

Purity:

>=99.95% or 99.99

Tantalum tube is largely applied to produce tantalum response vessel, tantalum heat exchangers(shell & tube heat exchanger), tantalum pipe line(piping or channel), tantalum condenser, tantalum agitator, tantalum cooler, tantalum boiler, tantalum bayonet heater, tantalum spiral (helical) coil, U-tube heat exchanger or "U" tube bundle heat exchanger during the substance sector for condensing, re-boiling, preheating and cooling of nitric acid, sulfuric acid, hydrochloric acid, formic acid and combinations of those acids with a great deal of other chemicals.

Tantalum Rod And Tantalum Bar

Tantalum-10% Tungsten and Tantalum-2.5% tungsten have a higher strength at elevated temperatures, and better corrosion resistance than pure tantalum.

Standard: ASTM B365

Grade: RO5200, RO5400, RO5252 (Ta-2.5W), RO5255 (Ta-10W)

Specifications: ¢ 0.25 ¢ 100mm

Executive Standard: ASTM B365-98

Ingredients Description:

Tantalum Sheet And Plate

Manhar Metal supplies sheets and plate products in a wide range of thicknesses and widths. We can offer flat rolled material cut to specific lengths or we can supply coiled sheet or strip shipped 0n cores. Although our products are typically produced to meet ASTM specifications, other specifications are available upon request.

Manhar Metal offers both powder metallurgy and typical electron beam processed tantalum sheet. The powder metallurgy grade tantalum is perfect for deep drawing and stamping applications.Its provides a fine grain structure and is isotropic. Therefore parts are less likely to be pitted or have rough surfaces.

For high temperature applications such as furnace parts . This product is engineered to significantly increase the product life by slowing grain growth at high temperature.

Tantalum Bolt And Fastener

Tantalum Bolt & Fastener can provide custom tantalum fastener solutions for your unique tantalum bolt, tantalum nut & tantalum screw applications. Just let us know the requirements of your tantalum fasteners and our engineering staff will help guide you to the best solution for your tantalum fastener application.

Manhar Metal tantalum fasteners are optimized concerning chemical and mechical performance. Manhar Metal's fasteners offer the full corrosion resitance of Tantalum, but are mechanically improved due to their steel core and Tantaline's patented alloy bonding technology.Manhar Metal's tantalum fasteners offer a corrosion performance that is well beyond that of titanium or other Speciality metals like zirconium or Hastalloy.

Tantalum fasteners are also extremely stable at high temperatures, since its melting point around 3000C. Furthermore, tantalum fasteners are also one of the most bio-compatible metals around and because of is high density (16.68 g/cm3) its radio-opaque.

All tantalum fasteners are available in commercially pure tantalum, tantalum 2.5% tungsten (Ta-2.5%W) and tantalum 10% tungsten (Ta-10%W).

Physical Properties

Density 16.6 g/cc

Melting Point 3290 K, 2996°C, 5462°F

Boiling Point 5731 K, 6100°C, 9856°F

Coefficient of Thermal Expansion (20°C) 6.5 x 10(-6) / °C

Electrical Resistivity (20°C) 13.5 microhms-cm

Electrical Conductivity 13% IACS

Specific Heat .036 cal/g/°C

Niobium Pipes And Tubes

Available grades:

Pure grade (ASTM B394 - R04210)

Niobium-zirconium1% alloy (ASTM B394 - R04261)

Temper condition:

Annealed

Dimension:

Inner diameter - 0.2 mm to 5 mm

Length - by request

Dimension for niobium welded tube upon request

Standard: ASTM B 394

Grade: RO4200 (pure Niobium ), RO4210 (Nb1%Zr)

Outer Diameter: 1.0-150mm

Wall thickness: 0.2- 10mm

Purity: ≥99.9% and ≥99.95%

Niobium Rods And Bars

|

Niobium Flanges

Manhar Metal is the leading niobium products SUPPLIERS and provider in India. Besides domestic market, Manhar Metal exports about 40 percent of its productivity overseas, including various of niobium wire, niobium rod, niobium plate, niobium, niobium tubes, and all kinds of niobium machining parts. The Niobium machining parts is the most competitive product of Manhar Metal. We can produce various niobium screw, nuts, elbows, flanges, valves and so on. The wire products has been exported to more than 40 countries and regions including United States, Canada, Germany, Brazil, Australia, Japan, Korea, France, Spain, Italy, India, Russia, Ukraine and so on.

We have been committed to providing customers the best products,

lowest prices and most prompt delivery.

We sincerely look forward to the long-term cooperation with you.

Niobium Fasteners

Niobium is an associated metal of tantalum ,characterized in high strength ,high conductivity ,resistance to corrosion by liquid base metals ,section with low neutron capture ,etc ,widely used for steel ,ceramics ,electronics ,nuclear energy industries and superconductor technology.

Special requirements to be agreed on by the supplier and buyer of negotiation .

NB:99.95%min

Niobium Sheets And Plates

Available grades :

Pure grade

Nb-Ti alloy

Nb-Zr alloy (Nb-Zr1%, Nb-Zr10%)

Temper condition :

Annealed

Surface :

As-rolled or machined to bright

Dimension :

Thickness: 0.1 mm to 30 mm

Width: 50 mm to 900 mm

Length: up to 2000 mm

Cut to size service available.

Specification :

ASTM B393

ASTM B884

Tungsten Pipes And Tubes

Manhar Metal selects high quality metal powder and technologic sintered in the hydrogen to produce tungsten pipe and other tungsten product s. Tungsten pipe is high purity and machinable. The crystal structure of tungsten tube is compact.

Properties

1. menchanical properties:

Hardness Hv>450

Density d>19.2g/cm3

2. microstructure(vertical section)

The fibred structure

The initial recrystallization temperature 1200--1250℃

Applications :

Used as the stell-making additive

For producing tungsten targets

For producing ion implantation parts

For rolling tungsten foil and punching tungsten discs

For producing electric light source parts and electric vacuum components

For producing heating elements and refractors in high temperature furnaces

For producing W-boats, and heating units in high temperature furnaces

Tungsten Fasteners

Manhar Metal supplies high-performance molybdenum and tungsten fasteners that are used in many demanding applications. Our high quality nuts and threaded reduce the binding common with lower quality fasteners while providing outstanding performance in high temperature and corrosive applications. We also manufacture machined screws, wire hangers, rivets and pins that play a critical role in refractory metal assemblies used in high temperature furnaces, glass glass melting equipment, and other applications.

Types

Hex Nuts

Threaded Rod

Machined Screws

Rivets

Pins

Coiled or Cut Wire

Formed Wire Hangers

Many standard fasteners are available for immediate delivery. We also make custom fasteners in our world-class machining and fabrication shop.

Eminent Attributes:

Immense Weldability

High Corrosion Resistance

High Recrystallization Properties

Ability to Withstand Extreme Temperatures

Tungsten Rods And Bars

High purity tungsten rods can be used as heat conductor, additive, crankshaft and cylinder barrel of automobile, parts of heat-resistant steel and electrode. High purity tungsten rods are mainly used in guns, rockets, satellites, airplanes and ships.

The purity (99.999%) tungsten bars are mainly used as materials for high standard bearing steels, automobiles, high-speed railways, high precision equipment, and high-tech weapons. The purity (99.99%) tungsten bars are mainly used in alloy tool steel, high quality clean steel, and high performance special steel, etc. The purity 99.95% tungsten products are mainly used to cast raw materials for ingredients and forging special steel and drawn steel wires.

Tungsten Sheets And Plates

Pure tungsten heavy metal plate is widely used in the construction of furnace tooling and parts and as a feedstock for the fabrication of parts for the electronics and semiconductor industries. Surface can be supplied in a shiny or matte; dependent upon thickness and width parameters

Tungsten has the highest melting point (3410°C or 6170°F) of all metals. The extremely high melting point of pure tungsten makes all the common manufacturing techniques used for metals such as iron impractical. Specialized methods make possible the processing of pure tungsten into rod, sheet, and wire for a wide variety of high temperature applications including incandescent lamp wire, TIG welding electrodes, high temperature heat shielding, etc

Application:

Since tungsten heavy metal has highest melting point among all the pure metals in the world,pure tungsten heavy metal plate is widely used in reflection shield, cover plate applied in the sapphire growth furnace, reflection shield, heating tape, connecting pieces applied in vacuum furnace, sputtering target applied in plasma coating film, and high temperature resistance boat.

Grade: W1,W2,W3

Purity :>=99.95%

Thickness:0.05-14mm

Tungsten Products

Tungsten copper nickel, tungsten copper iron, tungsten copper 80/20,thoriated tungsten,tungsten carbide Products:-rod, round, wire, sheet, foil, disc, square, ring, flat, rectangle

Tungsten carbidegrades:-yg-6, yg-8, yg-20

Products:-rod, sheet, plate

Tungsten is mainly used in the production of hard materials based on tungsten carbide, one of the hardest carbides, with a melting point of 2770 °c. wc is an efficient electrical conductor, but w2c is less so. wc is used to make wear-resistant abrasives, and "carbide" cutting tools such as knives, drills, circular, mining and turning tools used by the metalworking, woodworking, mining, petroleum and construction industries. carbide tooling is actually a ceramic/metal composite, where metallic cobalt acts as a binding (matrix) material to hold the wc particles in place. this type of industrial use accounts for about 60% of current tungsten consumption.

The jewellery industry makes rings of sintered tungsten carbide, tungsten carbide/metal composites, and also metallic tungsten. wc/metal composite rings use nickel as the metal matrix in place of cobalt because it takes a higher luster when polished. sometimes SUPPLIERSs or retailers refer to tungsten carbide as a metal, but it is a ceramic because of tungsten carbide's hardness, rings made of this material are extremely abrasion resistant, and will hold a burnished finish longer than rings made of metallic tungsten. tungsten carbide rings are brittle, however, and may crack under a sharp blow.

The hardness and density of tungsten are applied in obtaining heavy metal alloys. a good example is high speed steel, which can contain as much as 18% tungsten. tungsten's high melting point makes tungsten a good material for applications like rocket nozzles, for example in the ugm-27 polaris submarine-launched ballistic missile. tungsten alloys are used in a wide range of different applications, including the aerospace and automotive industries and radiation shielding.superalloys containing tungsten, such as hastalloy and stellite, are used in turbine blades and wear-resistant parts and coatings.

Molybdenum Flanges

Manhar Metal Flange fabricates steel forged flanges from the materials that best suit your project needs and budget. A popular metal for flange fabrication is chrome molybdenum. Chrome molybdenum is a high strength steel whose alloying elements are chromium and molybdenum and is commonly known as chrome moly molybdenum hardness and strength properties make it great for heavy duty projects. molybedenum however, is not recommended for projects that require not welding and does not have a high enough chromium content to be corrosion resistant, like stainless steel. molybdenum is a great choice for flanges because it can be hardened to reduce wear and tear .

Manhar Metal Flange fabricates flanges to your exact specifications and with the materials that suit your project needs. We are a flange SUPPLIERS and supplier, serving customers nationwide and internationally.

Molybdenum Fasteners

Pure Molybdenum fasteners have excellent heat resistance, with their melting point being at 2,623 degrees C. Useful for heat resistant devices such as sputtering equipment and high temperature furnaces. Available in sizes M3-M10.

Manhar Metal has a long track record of producing top of the line, customizable molybdenum fasteners at competitive prices.

Molybdenum screws are produced for high temperature vacuum environments. We produce three head types (fillister, pan & flat) in both ANSI and metric sizes. We stock these refractory screws in standard lengths, but can also produce custom lengths and custom features. Please take note of the sketch provided for screw specs.

Molybdenum refractory washers are available in both inch and metric sizes. Washers help to distribute the load of a threaded fastener. All standard sizes are available. We can also produce custom sizes.

Molybdenum Rods And Bars

Molybdenum bar is used as vacuum material, cathode for emitting tube, high temperature electrodes etc. Molybdenum rods/bars/pole is a material with silver gray or gray metallic luster. They are used for producing molybdenum line-cutting, filament, coil wire, lead wire support, electron vacuum components and grid, etc.

Application:

Molybdenum bar is mainly used in drawing thin molybdenum wire, molybdenum electrode and steel-making additives. Meanwhile, molybdenum bar is also widely used in the furnace industry for radiation screens, elements, and sintering trays

Molybdenum Sheets And Plates

Working primarily with Molybdenum , Manhar Metal supplies refractory metals cut to size for various applications and industries. Depending on our superior water-jet cutting, blanchard grinding, and surface grinding abilities, we pride ourselves on meeting our clients' unique requirements. We're pleased to accommodate parts up to 1 inch in thickness, up to 10 feet long, and up 8 feet wide, and we can cut details within the material as well. With many of our customers requiring material for high-temperature furnace components, we maintain an impressive stock and feature a two day turnaround. Also appropriate for applications as diverse as medical devices and furnace rails, our cut plates and sheet metal serve numerous high-performance applications

Basic Info.

Powder: Not Powder

Purity: 99.95min

Density:

10.2g/cm3

Melting Point:

2610c

Application Temperature Environment:

1500--1800c

Export Markets:

Global

Physical and chemical properties

(1) Density: 10.2g/cm3

(2) Surface roughness: < 1.6

(3) Purity: Mo99.95%min.

(4) Application temperature environment: 1500~1800

Chromium Coppers

BLOCK, ROD ,ROUND BAR,ROLLED BAR, SQUARE , HEX ,STRIPS, FLAT, ,RECTANGLES.

Chromium copper alloys are high copper alloys, containing 0.6 to 1.2% cr. the chromium copper alloys are used for their high strength, corrosion resistance and electrical conductivity. the chromium copper alloys are age hardenable, which, in this case, means that a change in properties occurs at elevated temperature due to the precipitation of chromium out of the solid solution. the strength of fully aged chromium copper is nearly twice that of pure copper and its conductivity remains high at 85% iacs, or 85% that of pure copper. these high strength alloys retain their strength at elevated temperatures. the corrosion resistance of chromium copper alloys is better than that of pure copper because chromium improves the chemical properties of the protective oxide film. chromium copper has excellent cold formability and good hot workability. it is used in applications such as resistance welding electrodes, seam welding wheels, switch gears, cable connectors, circuit breaker parts, molds, spot welding tips, and electrical and thermal conductors that require strength. chromium copper alloys are designated as uns c18050 through c18600; the cast alloys are c81400 through c81540.

The age hardening reaction occurs because the solid solubility of chromium in copper decreases as the temperature decreases. the structure of slow cooled chromium copper is a two phase mixture of chromium and alpha copper. superior mechanical properties are achieved by fast-cooling the chromium copper alloys from the annealing temperature, so the chromium remains in a supersaturated solid solution with the copper. followed by an aging treatment where the chromium precipitates from the solid solution forming a very fine dispersion of precipitates in the matrix. the microstructure of a quenched or quickly cooled chromium copper alloy appears similar to that of the unalloyed copper. a fast cool prevents the chromium from precipitating out of the solid solution, so the resulting cast structure consists of a single phase alpha copper structure. the first material to solidify is pure copper, followed by a eutectic mixture of alpha and chromium. the alpha and chromium eutectic material forms a lamellar structure in the interdendritic regions. the microstructure of the wrought alloy consists of equiaxed, twinned grains of alpha copper solid solution. typically the allow are cooled rapidly so the chromium remains in alpha copper solid solution. the tempering treatment allows the chromium to precipitate out of solution forming a dispersion of chromium precipitates throughout the matrix. the chromium precipitates, or hardening precipitates, can be very fine and may not be visible at low magnifications.

Chromium Zirconium Copper

WIRE ,BLOCK, ROD ,ROUND BAR, ROLLED BAR, SQUARE , FLAT,FOIL, SHEET , PLATE, SCRAP, INGOT ,RING, BUSHES, DISC

Chromium zirconium copper alloy are composited by three material. and the common chemical composition of this alloy is 0.5~1.2% chromium, 0.03~0.3% zirconium and the other is copper. cu.cr.zr. is often the best choice for applications where a combination of high electrical and thermal conductivity and high strength at higher temperatures is required. studies have shown that of all commercially available electrode materials for spot welding mid stee, the lowest electrode costs are obtained with chromium-zirconium copper. the properties of cu-cr-zr are obtained by alloying and through heat treatments combined with cold working. the metallurgical behaviour of this alloy is based on transformations at the atomic level.

CHROMIUM ZIRCONIUM COPPER ALLOY APPLICATION

Chromium zirconium copper alloy is used widely in areas where high electrical and thermal conductivity are required combined with good mechanical properties. this is a high strength, seam, high conductivity alloy for spot, butt and projection welding which is ideal for plain as well as coated and galvanized sheets. uses include resistance welding machine electrodes, seam welding wheels, spot welding tips, flash butt welding electrodes, anvil contact bars, electrical switch gear contacts & terminals, electrode holders, cable connectors, current carrying arms and shafts, circuit breaker parts, heat sinks, short circuit rings, mig welding contact tubes and many other applications where copper would normally be the ideal choice for high conductivity but is just not strong enough.

C18150 chromium zirconium copper is used extensively for cap style resistance welding electrodes. evidence suggests that it can provide less sticking and resist deformation longer than its chromium copper counterpart in some specific situations.

Production

The first heat treatment stage is solution annealing at approximately 1000 °c. at this temperature the chromium and zirconium atoms are randomly distributed in the copper matrix. the material is then quenched in water. between 400 and 700 °c the chromium and zirconium atoms have a tendency to form precipitates in the copper matrix, but the cooling is too rapid for precipitation to take place. the result is a supersaturated solid solution. the strength of this structure is only slightly higher than that of pure copper and foreign atoms in the copper matrix considerably reduce the electrical conductivity.

The supersaturated solid solution serves as a starting point for further heat treatments. The properties of cu.cr.zr. are achieved by ageing the material at a temperature below 500 °c.

The ageing conditions are very critical and are chosen so that the precipitations are coherent with the copper matrix, i.e. the atomic layers of copper continue through the precipitations. although the atomic layers continue through the boundary of precipitates the lattices on both sides of the boundary do not match each other completely. this mismatch causes strain which is responsible for the high mechanical strength.

Another consequence of ageing is that, as the number of foreign atoms in the matrix decreases the electrical conductivity becomes considerably higher. the mechanical properties of cu.cr.zr. are further improved by introducing a cold working process between solution annealing and ageing.

Nickel Alloy Pipes And Tubes

We are manufacturing a wide range of nickel pipes which are available to our clients in various grades like Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201) and Nickel 205 (UNS N02205). These are available in standard as well as customized lengths, thickness, sizes and dimensions as per the requirements of our clients.

Specifications :-

Grades :

Nickel 200 (UNS No.2200), Nickel 201 (UNS No.2201), Nickel 205 (UNS N0.2205)

Type:

Seamless / ERW / Welded/ Fabricated

Form:

Round, Square, Rectangular, Hydraulic etc.

Length:

Single Random, Double Random & Cut Length

End:

Plain End, Beveled End, Threaded

The salient features are as follows :

• Excellent mechanical & magnetic properties

• High thermal & electrical conductivity

• Low gas content & vapor- pressure

• Value Added Services

• Hot Dipped Galvanizing

• Epoxy & Fbe Coating

• Electro Polish

• Draw & Expansion

Nickel Alloy Buttweld Fittings

We offer to our clients, a wide range of butt-weld fittings which includes long/short radius elbows, equal/unequal tees, concentric/eccentric reducers, caps, cross, short/long neck stub-ends, long pipe bends of 3d/5d/6d/8d up to 22d, s/j/u/expansion bends & swivels. These are manufactured as per various industrial standards like ansi b 16. 9, b 16. 28 & mss sp-43.

Specifications :-

Grades :

Nickel 200 (UNS No.2200), Nickel 201 (UNS No.2201), Nickel 205 (UNS N0.2205)

Standards:

ASTM / ASME SB 336

Types :

long/short radius elbows, equal/unequal tees, concentric/eccentric reducers, caps, cross, short/long neck stub-ends

Application:

• Petrochemicals Plants

• Chemical Plants

• Industrial Machinery

• Power Industry

• Government Companies

Nickel Alloy Forged Fittings

We are engaged in manufacturing and supplying of Nickel Alloy Forged Pipe Fittings available in ASTM / ASME SB 564 / 160 / 472 standards. These are manufactured as per the industrial standards and are available to our clients in customized sizes and specifications.

Specifications :-

Grades :

Nickel 200 (UNS No.2200), Nickel 201 (UNS No.2201), Nickel 205 (UNS N0.2205)

Types :

Elbows, Equal/Unequal Tees, Concentric/Eccentric Reducers, Full/Half Couplings, Reducing Couplings, Caps, Cross, Unions, Hex/Reducing/Flash Bushings, Plugs, Nipples, Swage Nipples, Reducer Inserts, Boss, Laterals Street Elbows & Outlets/Branch Connections (Weldolets, Thredolets, Sockolets, Flexolets, Latrolets, Elbolets, Sweepolets, Insert Weldolets, Nippolets, Brazolets, Coupolets)

Application:

• Petrochemicals Plants

• Chemical Plants

• Industrial Machinery

• Power Industry

• Government Companies

Nickel Alloy Flanges

Our range of nickel flanges are ideal for application in diverse industry for high pressure and temperature applications. These flanges are designed with precision for easy installation. Apart from standard flanges, we also offer custom designed nickel flanges to meet the specific application requirements of the customers.

Specifications :-

Grades :

Nickel 200 (UNS No.2200), Nickel 201 (UNS No.2201), Nickel 205 (UNS N0.2205).

Types : Socket Weld, Slip On, Blind, Lapped, Screwed, Weld Neck, Long Weld Neck, Reducing, Spectacle, Ring Joint

Features:

• Durability

• Corrosion resistance

• Dimensional accuracy

• High strength

• Chemical resistance

• Excellent finish

Nickel Alloy Fasteners

We offer a comprehensive range of nickel fasteners manufactured using advanced technology to guarantee precision in design. These fasteners are widely used for assembling various machines, parts and components. Our range of nickel fasteners can be customized as per drawings and specifications provided by the clients.

Specifications :-

Grades :

Nickel 200 (UNS No.2200), Nickel 201 (UNS No.2201), Nickel 205 (UNS N0.2205)

Standard : ASTM / ASME SB 163 / 165 / 167 / 464/ 517 / 619 / 622 / 626 / 704 / 705

Types :

Industrial Bolts: Stud bolts, hex head bolts, socket hexagon head screw anchor bolts, u-bolts, j bolts, mushroom head square neck bolts, t- head bolts, wing screw bolts, eye bolts, eye bolts, foundation bolts, structural bolts.

Industrial Nuts: Hexagon nuts, hexagon coupling nuts, hexagon thin nuts, square nuts, hexagon castle nuts, self locking nut, hexagon domed cap nuts.

Industrial Washers: Plain washer, plain big & small washers, spring lock washers, spring washers heavy duty, tooth washers, star washers, tab washer with one & two tab.

Industrial Screws: Pan head slotted screws, hexagon head screws, cheese head slotted screws, countersunk head slotted screws, countersunk raised head slotted screws, Pan Phillipse Head Screws, Countersunk Phillipse Raised Head Screws.

Features :

• Optimum strength

• Corrosion resistance

• Long service life

• Fine finish

Nickel Alloy Bars And Wire

We are committed to offer a wide assortment of Nickel Alloys Rods, Bars, Wires to our valuable customers. Our products are available in various specifications, sizes, shapes and dimensions as per the working demand of the customer. These products are highly appreciated amongst our clients for their high mechanical strength and longer service life.

Specifications :-

Grades : Nickel 200 (UNS No.2200), Nickel 201 (UNS No.2201), Nickel 205 (UNS N0.2205)

Form : Square , Round , Hex , Flat, Wire In Black & Bright Finish

Range : 3.17 mm to 350 mm dia

We offer Nickel Round Bar as per the following specifications.

Standard: ASTM / ASME SB 160

The salient features are as follows :

• Market leading prices

• High quality

• Customization available

Nickel Alloy Sheet And Plate

We offer Premium quality Nickel Alloy Plate and Sheets, which is designed to meet with various industrial functions. These nickel plates and nickel sheets are offered by us in a variety of sizes and is offered at industry leading prices.

Specifications :-

Grades : Nickel 200 (UNS No.2200), Nickel 201 (UNS No.2201), Nickel 205 (UNS N0.2205)

Standard: ASTM / ASME SB 162 / 127 / 424 /168 / 443 / 574 / 462

Sheets & Plates In Form Of: Coils, foils, shim sheet, perforated sheet, strip, flats, blank (circle), ring (flange), etc.

Value Added Service:

• Heat treatment

• Annealed & pickling

• Rolling, cutting, bending, forging, minor fabrication, etc.

Stainless Steel Pipes And Tubes

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many applications. there are over 150 grades of stainless steel, of which fifteen are most commonly used. the alloy is milled into coils, sheets, plates, bars, wire, and tubing to be used in cookware,cutlery,household hardware,surgical instruments,major appliances, industrial equipment (for example, in sugar refineries) and as an automotive and aerospace structural alloy and construction material in large buildings. storage tanks and tankers used to transport juices and other food are often made of stainless steel, because of its corrosion resistance. this also influences its use in commercial kitchens and food processing plants, as it can be steam-cleaned and sterilized and does not need paint or other surface finishes.stainless steel is used for jewelry and watches with 316l being the type commonly used for such applications. it can be re-finished by any jeweler and will not oxidize or turn black.some firearms incorporate stainless steel components as an alternative to blued or parkerized steel. some handgun models. this gives a high-luster finish similar in appearance to nickel plating. unlike plating, the finish is not subject to flaking, peeling, wear-off from rubbing (as when repeatedly removed from a holster), or rust when scratched.

Some automotive SUPPLIERSs use stainless steel as decorative highlights in their vehicles.

Stainless Steel Buttweld Fittings

Stainless Steel Buttweld Fitting accomplish a lot of admiration by our clients owing to its high strength, dimensional correctness, high tension power, corrosion resistant and consistency. These products are used in various commercial, industrial and automobile industries. We manufacture these fittings using high grade of raw material by implementing most ultra modern technology. These products are clients can avail from us at various sizes, shapes and design as per the requirements.

Specifications :-

Grades :

Stainless Steel 202, 303, 304, 304L, 309, 310, 316, 316L, 316TI, 317, 317L, 321, 410, 416, 420, 430, 440C, 904L

Range : 15 NB To 300 NB

Types :

Bend (Long & Short)

Elbow (180 Deg., 90 Deg. & 45 Deg.)

Tee (Equal & Unequal)

Reducer (Concentric & Eccentric)

CAP, Stub end (Long &Short)

Nipple (Barrel)

Application:

• Petrochemicals Plants

• Chemical Plants

• Industrial Machinery

• Power Industry

• Government Companies

Stainless Steel Forged Fittings

Stainless Steel Forged Fitting is high tensile strength, strong, stable, corrosion and rust resistance as well as their high efficiency. We manufacture these forged fittings using premium quality materials in accordance with the quality standards. These products are available in various sizes, shapes and design as per the specific requirements of our clients. Our esteemed clients can avail from us these products at most reasonable prices.

Specifications :-

Grades :

Stainless Steel 202, 303, 304, 304L, 309, 310, 316, 316L, 316TI, 317, 317L, 321, 410, 416, 420, 430, 440C, 904L

Size: 15 NB To 100 NB

Types :

• Union

• Coupling

• Full Coupling

• Cross

• Forged Elbow

• Hex Nipple

• Plug

• Bushing

• Boss

• Insert

• Adapter

• Socket

• Forged Tee

• Olets

• Weldolet

• Sockolet

• Elbowlet

• Thredolet

• Nipolet

• Latrolet

• Sweepolet

• Half Coupling

Application:

• Petrochemicals Plants

• Chemical Plants

• Industrial Machinery

• Power Industry

• Government Companies

Stainless Steel Flanges

Our Stainless Steel Flanges are of one of the best quality. We also have an exclusive range of stainless steel flanges which is of high exclusive quality. Stainless Steel Flanges available in a spectrum of shape and sizes, our forged light weight weld flanges are manufactured using superior grade material such as stainless steel.

Specifications :-

Grades :

Stainless Steel 202, 303, 304, 304L, 309, 310, 316, 316L, 316TI, 317, 317L, 321, 410, 416, 420, 430, 440C, 904L

Range : ½” (15 NB) to 48 “ (1200NB) in 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, ASA 150, ASA 300

Types : Socket Weld, Slip On, Blind, Lapped, Screwed, Weld Neck, Long Weld Neck, Reducing, Spectacle, Ring Joint

Features:

• Dimensional accuracy

• High strength

• Durability

• Corrosion resistance

• Excellent finish

Stainless Steel Fasteners

We are offering a premium range of Stainless Steel Fasteners. These Stainless Steel Fasteners are made from very high quality raw material which ensures hassle free work performance at its user end. The provided pipes are well known for being in-line with internationally laid quality parameters as they are constructed from world class raw material. We let our range of products to go through a quality test before procurement so that their quality may be properly checked.

Specifications :-

Grades :

Stainless Steel 202, 303, 304, 304L, 309, 310, 316, 316L, 316TI, 317, 317L, 321, 410, 416, 420, 430, 440C, 904L

Size : M10 to M36

Types:

Bolts Stud Bolts, Hex Head Bolts, Socket Hexagon Head Screw Anchor Bolts, U-Bolts, J Bolts, Mushroom Head Square Neck Bolts , T- Head Bolts , Wing Screw , Eye Bolt , Eye Bolt, Foundation Bolts, Structural Bolts.

Application :

Stainless steel fasteners can be used in racing industries such as racing motorcycles and cars, sailing boats and medical equipment, etc.

We are a leading name, which is engaged in offering a comprehensive range of Stainless Steel Rods, Bars & Wire. The offered range is manufactured utilizing superior grade raw material such as stainless steel and allied, procured from reliable vendors of the market. In addition to this, the offered range is tested on different parameters to ensure its tandem with the highest quality norms and standards.

Stainless Steel Rods Bars And Wire

We are a leading name, which is engaged in offering a comprehensive range of Stainless Steel Rods, Bars & Wire. The offered range is manufactured utilizing superior grade raw material such as stainless steel and allied, procured from reliable vendors of the market. In addition to this, the offered range is tested on different parameters to ensure its tandem with the highest quality norms and standards.

Specifications :-

Grades :

Stainless Steel 202, 303, 304, 304L, 309, 310, 316, 316L, 316TI, 317, 317L, 321, 410, 416, 420, 430, 440C, 904L

Diameter : 6.0-400 mm

Standards : GB, JIS, DIN, ASTM

Alloy Pipes And Tubes

We are a leading name in successfully handling the requirements of Alloy Pipes & Tubes .With the pipes manufactured at par with international standards, we have with us necessary support of latest equipment that helps us in developing process knowhow as well as sound production practices that are second to none. Following well defined and stringent de-oxidation practice for ensuring macro inclusions are floated out from molten metal.

Specifications :-

Grades : Gr P 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91

ange : ½” NB TO 24” NB IN SCH 20 , 30, STD, 40 , 60 , 80 , XS , 100 , 120 , 140 , 160 & XXS as Per NACE MR 01 75

Type : SEAMLESS / FABRICATED

length : Single Random, Double Random & Cut Length

End : Plain End, Bevelled End, Threaded

Alloy Steel Pipe

Standard : ASTM / ASME A 335

Grade : Gr P 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91

Value Added Sevices

• Bending

• Draw & Expansion

• Customized Pipe

The salient features are as follows :

• Excellent mechanical & magnetic properties

• High thermal & electrical conductivity

• Low gas content & vapor- pressure

• Value Added Services

• Hot Dipped Galvanizing

• Epoxy & Fbe Coating

• Electro Polish

• Draw & Expansion

Alloy Steel Buttweld Fittings

We hold the expertise in manufacturing, and exporting Alloy Fittings. Advanced technologies are used in our custom for each product we build. These fittings are designed outstandingly with various specifications. It is easy for performing and featured with noise free functioning, less maintenance, easy to relocate. This is normally used in the industries for joining the pipes.

Specifications :-

Grades :

WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91.

Range : 1/2"NB TO 48"NB IN SCH: 20, 30, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75

Standard : ASTM / ASME A/SA 234

Types : long/short radius elbows, equal/unequal tees, concentric/eccentric reducers, caps, cross, short/long neck stub-ends

Other Fittings

Customised Fittings

Hydraulic Fittings

Instrumentation Fittings

Value Added Services

• Hot Dipped Galvanizing

• Sand Blasting

Alloy Steel Forged Fittings

We hold the expertise in offering premium quality Alloy Steel Screwed & Forged Fittings to our esteemed client. These products are checked on various well defined parameters. They test is conducted under the guidance of our expert professionals.

Specifications :-

Grades : F 5, F 9, F 11, F 12, F 22, F 91.

High Speed Steel (HSS), HCHCR & OHNS in Grade : M2, M3, M35, M42, T-1, T-4, T-15, T-42, D2, D3, H11, H13, OHNS-01 & EN52.

EN Series in Grade : EN-1A, EN-3B, EN-8, EN-9, EN-16, EN-18, EN-19, EN-24, EN-29B, EN-31, EN-32B, EN-36, EN-36C, EN-42J, EN-45, EN-47, EN-48A, EN-100, EN-111, EN-202, EN-352, EN-353, EN-1117 Etc.

Range : ¼” NB to 4” NB in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Standard : ASTM A182

Types : Elbows, Equal/Unequal Tees, Concentric/Eccentric Reducers, Full/Half Couplings, Reducing Couplings, Caps, Cross, Unions, Hex/Reducing/Flash Bushings, Plugs, Nipples, Swage Nipples, Reducer Inserts, Boss, Laterals Street Elbows & Outlets/Branch Connections (Weldolets, Thredolets, Sockolets, Flexolets, Latrolets, Elbolets, Sweepolets, Insert Weldolets, Nippolets, Brazolets, Coupolets)

Other Fittings

Customised Fittings

Hydraulic Fittings

Instrumentation Fittings

Value Added Services

• Hot Dipped Galvanizing

• Sand Blasting Government Companies

Alloy Steel Flanges

SUPPLIERS, Exporter, Importer, and Supplier of superior quality Alloy Steel Flanges. The Alloy Steel Flanges offered by us are strictly tested by our experts on various parameters, in order to meet the quality standards. Our Alloy Steel Flanges are widely used in various industrial applications. Moreover, these Alloy Steel Flanges are available in different sizes and specifications as per the client’s needs.

Specifications :-

Grades : F 5, F 9, F 11, F 12, F 22, F 91.

High Speed Steel (HSS), HCHCR & OHNS in Grade : M2, M3, M35, M42, T-1, T-4, T-15, T-42, D2, D3, H11, H13, OHNS-01 & EN52.

EN Series in Grade : EN-1A, EN-3B, EN-8, EN-9, EN-16, EN-18, EN-19, EN-24, EN-29B, EN-31, EN-32B, EN-36, EN-36C, EN-42J, EN-45, EN-47, EN-48A, EN-100, EN-111, EN-202, EN-352, EN-353, EN-1117 Etc.

Range : ½” NB to 60” NB

Standard :150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS

ASA 150#, ASA 300# DIN ND 6,10,16,25,40 Etc.

Nace : NACE MR 01-75, MR 01 03

Types : Socket Weld, Slip On, Blind, Lapped, Screwed, Weld Neck, Long Weld Neck, Reducing, Spectacle, Ring Joint

Standard: ASTM / ASME A/SA 182 & A 387

Grade : F1, F5, F9, F11, F12, F22, F91.

SPECIFICATIONS AS PER THE INTERNATIONAL STANDARD ASTM, ASME, API, AISI, BS, ANSI, DIN, JIS, MSSP, NACE

Value Added Services :

• CNC Machining

• Customized Flanges

Alloy Steel Fasteners

Made available in different materials grades, sizes and other specifications, the Alloy Steel Fasteners are thoroughly tested for quality before their delivery. That is why, we are considered as one of the leading Alloy Steel Fasteners suppliers and Exporters in the market.

Specifications :-

Grades :

ASTM / ASME A 193 B 6, B 7/ B 7M, B 16/ ASTM / ASME A 194 GR. 2, 2HM, 2H, GR 6, B 7, B 7M.

Types :

Industrial Bolts: Stud bolts, hex head bolts, socket hexagon head screw anchor bolts, u-bolts, j bolts, mushroom head square neck bolts, t- head bolts, wing screw bolts, eye bolts, eye bolts, foundation bolts, structural bolts.

Industrial Nuts: Hexagon nuts, hexagon coupling nuts, hexagon thin nuts, square nuts, hexagon castle nuts, self locking nut, hexagon domed cap nuts.

Industrial Washers: Plain washer, plain big & small washers, spring lock washers, spring washers heavy duty, tooth washers, star washers, tab washer with one & two tab.

Industrial Screws: Pan head slotted screws, hexagon head screws, cheese head slotted screws, countersunk head slotted screws, countersunk raised head slotted screws, Pan Phillipse Head Screws, Countersunk Phillipse Raised Head Screws.

Specialty:

• Tough construction

• Dimensionally precise

• Anti-corrosive

• High resilience

Used In:

• Oil and Gas Industry

• Engineering Industry

• Petrochemical Industry

• Construction Industry

• Water Treatment Industry

• Pipe and Tubing Industry

Alloy Steel Rods Bars And Wire

Highly appreciated for its durability, sturdy construction and tear-resistance, our range of Carbon & Alloy bars & Wires is quality tested at ours and the vendors' premises. We also offer these in different alloy grades, which is mentioned below:

Specifications :-

Grades : F 5, F 9, F 11, F 12, F 22, F 91.

High Speed Steel (HSS), HCHCR & OHNS in Grade : M2, M3, M35, M42, T-1, T-4, T-15, T-42, D2, D3, H11, H13, OHNS-01 & EN52.

EN Series in Grade : EN-1A, EN-3B, EN-8, EN-9, EN-16, EN-18, EN-19, EN-24, EN-29B, EN-31, EN-32B, EN-36, EN-36C, EN-42J, EN-45, EN-47, EN-48A, EN-100, EN-111, EN-202, EN-352, EN-353, EN-1117 Etc.

We offer Alloy Bar as per the following specifications.

Standard:ASTM / ASME A/SA 182

Form : Round

Finish :

Bright

Black

Range : 20 mm To 300 mm Dia in 100 mm TO 6000 mm Length

Value Added Services:

• Annealed

• Forged & Peeled

• Rolling

• Cutting

• 100% Ultrasonically tested.

Alloy Steel Sheet And Plate

We are reputed SUPPLIERSs and exporters of high quality Sheets & Plates. These products are globally known for its compliance with the industry set norms. We offer them in various grades that meet the requirements of the client. Our range comprises of Stainless Steel Sheets & Plates.

Specifications :-

Grades : F 5, F 9, F 11, F 12, F 22, F 91.

High Speed Steel (HSS), HCHCR & OHNS in Grade : M2, M3, M35, M42, T-1, T-4, T-15, T-42, D2, D3, H11, H13, OHNS-01 & EN52.

EN Series in Grade : EN-1A, EN-3B, EN-8, EN-9, EN-16, EN-18, EN-19, EN-24, EN-29B, EN-31, EN-32B, EN-36, EN-36C, EN-42J, EN-45, EN-47, EN-48A, EN-100, EN-111, EN-202, EN-352, EN-353, EN-1117 Etc.

Standard: ASTM / ASME A/SA 387

Range : 5 mm To 200 mm thick in 1000 mm TO 2500 mm width & 2500 mm to 12500 mm Length

Sheets & Plates In Form Of : Sheet, Plates, Flat, Strips, Profile, Blank ,Circle, Ring etc.

Value Added Service :

• Cutting

• Bending

• Forging

• Rolling

• Heat Treatment

• Minor Fabrication

Mild Steel Pipes And Tubes

Backed by a team of skilled professionals, we are engaged in offering our clients a wide assortment of Mild Steel Pipe & Tube. The products offered by our organization are manufactured using superior quality raw material and modern technology at our well equipped manufacturing unit, which ensures high durability at its users end. These products are also provided in different sizes and dimensions as per the exact requirements of our clients.

Popular for:

• Dimensional accuracy

• High performance

• High durability

• Good malleability properties

• High efficiency

Used in:

• Production of steel furniture

• Material storage rakes

• Machine components

• Railway wagon

• Coaches

Mild Steel Buttweld Fittings

With our rich industry experience, we are engaged in offering our clients a wide range of Mild Steel Butt Weld B & W Fitting. These fittings are manufactured with an assemblage of quality raw material at our manufacturing unit. Our offered fittings are stringent tests to ensure strict adherence to international industry standards and parameters. These are also available in different specifications in order to meet the diverse requirements of our valuable clients.

Features:

Easy to fit

Minimum maintenance

Dimensional accuracy

Mild Steel Forged Fittings

Mild Steel Forged Fittings Backed by a team of skilled professionals, we are actively engaged in offering our clients a wide range of Mild Steel Forged Fitting. These fittings are manufactured by making use of optimum quality basic material and advanced technology. Our offered products are available in standard sizes and can also be customized as per the need of the clients across the nation. These products are delivered to the clients within the promised time.

Preferred for:

High tensile strength

Dimensionally accuracy

Easy installation

High durability

Applications:

Construction industry

Engineering industry

Mechanical industry

Commercial sector

Food industry

Types : Elbows, Equal/Unequal Tees, Concentric/Eccentric Reducers, Full/Half Couplings, Reducing Couplings, Caps, Cross, Unions, Hex/Reducing/Flash Bushings, Plugs, Nipples, Swage Nipples, Reducer Inserts, Boss, Laterals Street Elbows & Outlets/Branch Connections (Weldolets, Thredolets, Sockolets, Flexolets, Latrolets, Elbolets, Sweepolets, Insert Weldolets, Nippolets, Brazolets, Coupolets)

Other Fittings

Customised Fittings

Hydraulic Fittings

Instrumentation Fittings

Value Added Services

• Hot Dipped Galvanizing

• Sand Blasting Government Companies

Mild Steel Flanges

Our enterprise is a prominent SUPPLIERS, trader and supplier of utmost quality Mild Steel Flange. Available in various specifications, these products are manufactured utilizing quality-approved raw material and other basic components. These premium quality products are available as per clients' specifications and requirement. Our offered products are delivered at industry leading prices to the end user scattered across the country.

Known for:

High durability

Resistant to corrosion

High tensile strength

High performance

Easy installation

Dimensional accuracy

High tolerance

Mild Steel Fasteners

We are a leading SUPPLIERS, supplier, exporter and trader of Bolts, Screws, Fasteners and Nuts. In order to cater to the diversified requirements of various industries, we are offering Mild Steel Fastener. We manufacture this product with ultra grade mild steel that is collected from well-established raw material suppliers. This fastener is used for fastening the objects in various industries and ensure strong bonding. We are availing it in customized designs and varied shapes.

Salient Features:

. High tensile strength

. Rust resistance

. Perfect finish.

Types :

• Industrial Bolts:

Stud bolts, hex head bolts, socket hexagon head screw anchor bolts, u-bolts, j bolts, mushroom head square neck bolts, t- head bolts, wing screw bolts, eye bolts, eye bolts, foundation bolts, structural bolts.

• Industrial Nuts:

Hexagon nuts, hexagon coupling nuts, hexagon thin nuts, square nuts, hexagon castle nuts, self locking nut, hexagon domed cap nuts.

• Industrial Washers:

Plain washer, plain big & small washers, spring lock washers, spring washers heavy duty, tooth washers, star washers, tab washer with one & two tab.

• Industrial Screws:

Pan head slotted screws, hexagon head screws, cheese head slotted screws, countersunk head slotted screws, countersunk raised head slotted screws, Pan Phillipse Head Screws, Countersunk Phillipse Raised Head Screws.

Mild Steel Rods Bars And Wire

Mild steel, also called plain-carbon steel, is the most common form of steel because its price is relatively low while it provides material properties that are acceptable for many applications. Low-carbon steel contains approximately 0.05–0.3% carbon making it malleable and ductile. Mild steel has a relatively low tensile strength, but it is cheap and malleable. It is often used when large quantities of steel are needed, for example as structural steel.

Aluminium Ingot

|

Indium Wire

WIRE ,INGOT,SHEET,FOIL,RINGS

The metal is very soft, malleable and easily fusible, with a melting point higher than sodium, but lower than lithium or tin indium is a very soft, silvery-white, highly ductile, relatively rare post-transition metalwith a bright luster. It is so soft (mohs hardness 1.2) that the metal can be cut with a knife, as can sodium. indium is an post-transition metal and chemically, is the intermediate element between its group 13 neighbors gallium andthallium. an indium atom has 49 electrons, having an electronic configuration of 4d105s25p1.

In its compounds, indium most commonly loses its three outermost electrons, becoming indium ions, in3+, but in some cases the pair of 5s-electrons can stay within the atom, indium thus being oxidized only to indium(i), in+. This happens due to the inert pair effect, which occurs because of the stabilization of 5s-orbital due to relativistic effects, which are stronger closer to the bottom of the periodic table. in is the more stable oxidation state. thallium (indium's heavier homolog) shows an even stronger effect, making oxidation to thallium(i) more likely than to thallium(iii), making +1 the more likely oxidation state,[9] whereas gallium (indium's lighter homolog) commonly shows only the +3 oxidation state. thus, although thallium is a moderately strong oxidizing agent, indium is stable and indium is a powerful reducing agent.

Brass Sheets And Plates

We offer excellent quality Brass Sheets and Plates as per the demand of the customer. The Brass Roofing Sheets manufactured by our company are available in various compositions like 70-30, 63-37, 60-40. The hardness and size of brass sheets provided by us may differ depending on the requirement of the customer. We offer best quality brass sheets at nominal charges and are known widely as one of the well known Polished Brass Plate SUPPLIERSs in the market.

BRASS:

Free Cutting Brass, Leading Brass, Foreign Brass, Reviting Brass, Lead Free Brass, Neval Brass.

FORMS :

Round Hexagonals, Squares, Rods, Tubes, Sheets, Strips, Foils, Busbars, Plate, Flats, Wire, Tubings, Sections & Bushes.

Specifications :

Size :

1000mm to 2500mm

Thickness :

0.3mm to 25mm

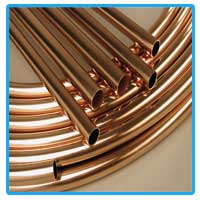

Copper Products

Leading SUPPLIERS and Exporter of Copper Products such as Copper Pipes, Copper Tubes, Copper Foils, Copper Rods, Copper Flats and Copper Butt Weld Fittings from Mumbai. Where low maintenance and corrosion resistance is required, stainless steel plates are a natural choice and are used in a diverse range of applications from modern architecture for cladding or fascias, to the food hygiene industry due to its anti-bacterial qualities.

Copper

Electrolytic Copper, Electrolytic Tough Pitch Copper, Deoxidised Copper, General Purpose Commercial Copper.

FORMS :

Round Hexagonals, Squares, Rods, Tubes, Sheets, Strips, Foils, Busbars, Plate, Flats, Wire, Tubings, Sections & Bushes

Phosphor Bronze

Our company is highly acclaimed in offering a wide range of PhosphorBronze.

The specifications of this product include :

BS2870 / BS2875 : PB103 - BS2874 : PB102 - NES838 BS2874 : PB104/ BS B24 (DTD265A*) (Colbronze) - BS1400 : PB1 ASTM B139 : C54400 (Colphos 90).

Phosphor Bronzes, more accurately described as Tin Bronzes, are alloys of copper where tin is the main alloying element with phosphorus added primarily as a deoxidant. Alloys containing up to about 9% tin are wrought. Alloys containing from about 10-12% tin are used as-cast. They are strong, corrosion resistant alloys with many traditional uses in marine environments and in electrical and electronic engineering where their especially at the higher cast level, imparts good wear resistance for traditional use in bearing components.

Gunmetal

|

Inconel Metal

Inconel Is An Alloy Of Nickel Containing Chromium And Iron,Resistant To Corrosion At High Temperatures.Inconel Is A Family Of Austenite Nickel-Chromium Based On Super Alloys.

Manhar metal supply corporation deals in inconel grade 600, 601, 625, 718, 750, 800, 800h,825, 901.

PRODUCTS

Various forms of inconel that we deal in are wire ,spring hard wire,fller wire,block, rod ,round bar,bright bar, rolled bar, square , hex ,strips, flat,foil, sheet ,coil,slitting coil, plate, tubes, pipe,seamless pipes , capillary tubes ,fittings, elbow,tee, reducer, ,union coupling,nipple, flanges, fastner, nut bolt , screwed fittings, forge fittings,ferrule fittings ,buttweld fittings , wire mesh , coupling, ,crucibal, ,scrap, , nozzles ,ingot,ring,bushes,disc,,rectangles

PROPERTIES

Inconel Alloys Are Oxidation And Corrosion Resistant Materials Well Suited For Service In Extreme Environments Subjected To Pressure And Heat.When Heated,Inconel Forms A Thick,Stable,Passivating,Oxide Layer Protecting The Surface From The Further Attack.Inconel Retains Strength Over A Wide Temperature Range,Attractive For High Temperature Applications Where Aluminium And Steel Would Succumb To Creeps A Result Of Thermally Induced Crystal Vacancies.Inconel’s High Temperature Strength Is Developed By Solid Solution Strengthening Or Precipitation Strengthening, Depending On The Alloy.Inconel Alloys Are Typically Used In High Temperature Applications.It Is Sometimes Referred To In English As “Inco” (Or Occasionally “Incone”). Common Trade Names For Inconel 625, Hayness 625, Nickel Vac 625.

USES

Inconel Is Often Encountered In Extreme Environments. It Is Common In Gas Turbine Blades, Seals, And Combustors, As Well As Turbocharger Motors And Seals, Electric Submersible Well Pump Motor Shafts, High Temperature Fastners, Chemical Processing And Pressure Vessels, Heat Exchanger Tubing, Steam Generators And Core Components In Nuclear Pressurized Water Reactors,Natural Gas Processing With Contaminants Such As H2s Co2 , Firearm And Suppressor Blast Baffles,And Formula One, Nascar And Apr, Llc Exhaust Systems. It Is Also Used In The Turbo System Of The 3rd Generation Mazda Rx7, And The Exhaust Systems Of High Powered Rotary Engined Norton Motorcycles Where Exhaust Systems Temperatures Reach More Than 1,000˚C, Inconel Is Increasingly Used In The Boilers Of Waste Incinerators. Inconel 718 Is Commonly Used For Cryogenic Storage Tanks, Downhole Shafts And Wellhead Points.

Rolled Inconel Was Frequently Used As The Recording Medium By Engraving In Black,Box Recorders On Aircraft. Alternatives To The Use Of Inconel In Chemical Applications Such As Scrubbers, Columns, Reactors, And Pipes Are Hastalloy, Perfluoroalkoxy(Pfa)Lined Carbon Steel Or Fiber Reinforced Plastic.The Exhaust Valves On Nhra Top Fuel And Funny Car Drag Racing Engines Are Made Of Inconel.Inconel Is Also Used In Manufacture Of Exhaust Valves In High Performance Aftermarket Turbo And Supercharged Mazda Miata Engine Builds(Se Flying Miata Inc)

PRODUCT INFO:-

INCONEL 600 (ALLOY 600):

Alloy 600 Has Excellent Resistance To Oxidation At Temperature Upto 1175 Degree Celsius And Is Also Resistant To A Variety Of Corrosive Media. It Retains Its High Strength Up To About 650 Degree Celsius. Even At Lowest Temperatures, Alloy 600 Has Good Mechanical Properties. Due To Its Resistance To Chloride Stress Corrosion Cracking, Alloy 600 Is Employed In Components Of Power Plants. This Grade Can Be Welded Without Thermal Retreatmnt.

INCONEL 601 (ALLOY 601):

Alloy 601 Has Very Good Properties At High Temperature And Is Oxidation Resistant As Well As Scale Resistant At Temperatures Of Up To 1250 Degree Celsius. The High Chromium Content Results In Good Resistance Against Oxidation, Carburisation And Sulfurous Media. The Aluminium And Nickelcontent Result In A Further Improvement Of The Oxidation Resistance.

INCONEL 625(ALLOY 625):

Excellent Corrosion Resistance With High Strength And Ductiliy At Temperature Upto 700 Degree Celsius Applicable Upto 1100 Degree Celsius Alloy 625 Is Weldable Without Thermal Retreament.

INCONEL 800(H) (ALLOY 800 H):

This Alloy Is Resisitant To Corrosion Resulting From Hydrogen And Hydrogen Sulfide As Well As To Stress Corrosion Cracking.It Is Highly Heat Resistant And Insensitive To The Separation Of Sigma Phase.Alloy 800 H With Controlled Carbon Content Improves Futhermore The Creep Strength Depending On Time In Solution Annealed Condition.

INCONEL 825 (ALLOY 825) :

Resistance To Sulfuric Acid, Phosphoric Acid Solvents And Sea Water As Well As To Many Oxidising Chemicals.Alloy 825 Has Good Resistance To Reducing Acid. It Can Be Employed Without Thermal Treatment After The Welding Process.

HASTALLOY C-276 (ALLOY C-276) :

Today probably one of the best and manifold alloys 0n the market hence employed in extreme corrosive reducing and oxidising applications. alloy c-726 has excellent resistance to strong oxidizing media contaminated by chloride, dry chloride acid, formate acid, acetic acid, acetic hydride solution, sea water solutions and saline solutions. the alloy is resistant to the corrosive influence of wet hydrochloride acid, hydrochloride dioxide solutions.

HASTALLOY C-4 (ALLOY C-4 :

Excellent resistance against strong oxidising agents, hot contaminated miniral acids,solvent, chlorine and media contaminated by chlorine(organic and inroganic), dry chloric acid, formic acid, acetic acid, acetic hyride solutions, sea water solutions, and saline solutions. this alloy has high ductility and corrosive resistance even in temperature range of 650-1040 degree celsius.alloy c-4 is resistant against the formation of grain boundary carbides and can thus be used in most cases without heat-treatment after welding.

INCOLLOY DS (ALLOY DS):

Alloy ds is a heat resistant ni-cr-fe alloy with si addition for the employment at high temperatures where sufficient strength and corrosive resistance are required. alloy ds is heat-resistant upto 1100 degree celsius when in fresh air. this alloy is especially resistant against changing oxidising / reducing conditions as well as the formation of sigma phase in the critical temperature range of 590-870 degree celsius . furthermore it is green rot. due to high strength and heat resistance to alloy ds, smaller sections than usual can be manufactured from this material.

ALLOY 20 :

Alloy 20 is a high –alloyed stainless steel. its corrosion properties surpass those of usual stainless qualities. for example .alloy 20 has excellent stress corrosion to boiling 20-40 % sulfuric acid. although alloy 20 was originally developed for usage in sulfuric environment, its range application has been steadily extended and today also includes machining of artificial rubber, plastic, synthetic fibre etc.in pharmaceutical and food producing application,where purity has to be guaranteed, alloy 20 is employed to prevent metallic contamination. the most important advantages of this grade are its excellent mechanical properties as well as its comparatively easy machine ability.

MONEL 400(ALLOY 400), MONEL K500 (ALLOY K-500):

About monel 400: alloy 400 is especially resistant to saline and other acids in ventilated condition.it is successfully employed in the salt winning process. alloy 400 is especially suited for employment in the sea barkage water at high speed, where resistance against cavitation and erosion is of great importance. this alloy is very resistant to solvents, glass-etching agents, sulfuric and other acids and virtually to all alkalis. this grade is not sensitive to stress corrosion cracking in oxidizing media. alloy 400 can be employed at temperatures up to 550 degree celsius.

ABOUT MONEL-500:

An age-hardening alloy with the same corrosion resistance as alloy 400, though with increased tensile strength and hardness. alloy k-500 retains its strength upto temperature of about 650 degree celsius.

MONEL K-500 (ALLOY K-500):

An age-hardening alloy with the same corrosion resistance as alloy 400, though with increased tensile strength and hardness.alloy k-500 retains its strength up to temperature of about 650 degree celsius.

Nimonic Metal

Nimonice Is A Registered Trademark Of Manhar Metal Supply Corporation That Refers To A Family Of Nickel-Based-High Temperature Low Creep Superalloys. Nimonic Alloys Typically Consist Of More Than 50% Nickel And 20% Chromium With Additive Such As Titanium And Aluminium.The Main Use Is The Gas Turbine Components And Extremely High Performance Reciprocating Internal Combustion Engines.

Nimonic Is A Series Of Nickel-Chromium Alloys Which Are Used Primarily For Creep Resistance, High Strength And Stability At High Temperature. It Is The Basic Jet For Engine Applications. A Nickel-Chromium Alloy Similar To Nimonic Alloy Has Made Precipitation Hardenable By Additions Of Aluminium And Titanium.The Alloy Has Good Corosion And Oxidation Resistance And High Tensile And Creep-Rupture Properties At Temperatures To 1500˚F (815˚C).Used For Gas-Turbine Components(Blades,Rings And Disc), Bolts,Tube Supports In Nuclear Steam Generators,Die-Casting Inserts And Crores, And Exhaust Valves In Internal-Combustion Engine.

Products

Wire ,Spring Hard Wire,Fller Wire,Block, Rod ,Round Bar,Bright Bar, Rolled Bar, Square , Hex ,Strips, Flat,Foil, Sheet , Coil,Sleeting Coil, Plate, Tubes, Pipe,Seamless Pipes , Capillary Tubes ,Fittings, Elbow,Tee, Reducer, ,Union Coupling,Nipple, Flanges, Fastner, Nut Bolt , Screwed Fittings, Forge Fittings,Ferrule Fittings ,Buttweld Fittings , Wire Mesh , Coupling, ,Crucibal, ,Scrap, , Nozzles ,Ingot ,Ring, Bushes, Disc, ,Rectangles.

Nichrome Metal

Nichrome Is A Renowned Packaging Machines Manufactirer Of India. Nichrome’s Versatile, High Quality And Flexible Range Of Machines Have Won The Trust Of Many Established Brands In The Market.It Is The Oldest Documented Form Of Resistance Heating Alloy.Nichrome Is Used In Avery Wide Variety Of Devices Where Electric Heating Is Required. Nichrome Is Used In The Explosives And Fireworks Industry As A Bridgewire In Electric Ignition Systems, Such As Electric Matches And Model Rocket Igniters. Industrial And Hobby Hot Wire Foam Cutters Use Nichrome. Nichrome Is Commonlu Used In Ceramic As An Internal Support Structure To Help Some Elements Of Clay Sculptures Hold Their Shape While They Are Still Soft.

Nichrome Is Used For Its Ability To Withstand The High Temperatures That Occur When Clay Work Is Fired In A Klin. Nichrome Can Also Be Used As An Alternative To Plantinum Products For Flame Testing By Colouring The Non-Luminous Part Of A Flame To Detect Cations Such As A Sodium, Potassium, Copper, Calcium Etc.The Alloy Tends To Be Expensive Due To Its High Nickel Content. Distributor Pricing Is Typically Indexed To Market Prices For Nickel. Other Areas Of Usage Include Motorcycles Silencers, In Certain Areas In The Microbiological Lab Apparatus, As The Heating Element Of Plastic Extruders. The Heating Resistance Of Nichrome Wire Must Be Stable In Air When Hot. Nichrome Wire May Be Also Used As The Coils Of Elecronic Cigrattes For Vaping.

Beryllium Coppers

Manhar Metal Supply Corporation has a wide range of optimum quality beryllium copper products that are precisely designed for perfection. These products find extensive application in a host of industries and have gained huge appreciation for their excellent features such as durability and reliability. Incorporating large blocks of beryllium copper, or other copper alloys, in the planning stages of plastic mold design is essential for achieving faster production cycles and the highest return on investment over the life of the mold.

Beryllium copper mold materials have hardness properties comparable to tool steels, but with superior thermal conductivity. Beryllium copper plate, block, bar and rounds are available in a choice of strength, hardness and thermal conductivity levels.

High fatigue strength

Beryllium copper is known to have high fatigue strength with high bending stress and has been used as an extremely long life, high reliable spring material.

Beryllium Copper Strip

Manhar Metal Supply Corporation has a wide range of optimum  quality Beryllium copper products that are precisely designed for perfection. These products find extensive application in a host of industries and have gained huge appreciation for their excellent features such as durability and reliability.

quality Beryllium copper products that are precisely designed for perfection. These products find extensive application in a host of industries and have gained huge appreciation for their excellent features such as durability and reliability.

Specifications: Elevated temperature properties

Beryllium copper can be used in a wide range of temperatures and has an excellent properties at elevated temperatures.

High strength

Beryllium copper can attain high tensile strength, to a maximum of 1500n / mm 2, by precipitation hardening and therefore can endure very high bending stress as a spring material

High electrical conductivity

The electrical conductivity of beryllium copper is 20 to 60% iacs, depending on type. Therefore beryllium copper has been used as a high current density spring material.

Other Information

Minimum Order Quantity: 25 Kilogram

Production Capacity: AS REQUIRED

Delivery Time: EX-STOCK

Packaging Details: STANDARD

Beryllium Copper Sheets And Plates

Typical Physical Properties:

Density (g/cm3): 8.36

Density before age hardening (g/cm3): 8.25

Elastic Modulus (kg/mm2 (103)): 13.40

Thermal Expansion Coefficient (20 °C to 200 °C m/m/°C): 17 x 10-6

Thermal Conductivity (cal/(cm-s-°C)): 0.25

Melting Range (°C): 870-980

Physical property:

1.High strength

2.High hardness

3.High elasticity

4.Superior fatigue resistance

5.Superior abrasion resistance

6.Superior mouldability and isotropy

Beryllium Copper Flat Bar

Typical Physical Properties:

Density (g/cm3): 8.36

Density before age hardening (g/cm3): 8.25

Elastic Modulus (kg/mm2 (103)): 13.40

Thermal Expansion Coefficient (20 °C to 200 °C m/m/°C): 17 x 10-6

Thermal Conductivity (cal/(cm-s-°C)): 0.25

Melting Range (°C): 870-980

Physical property:

1.High strength

2.High hardness

3.High elasticity

4.Superior fatigue resistance

5.Superior abrasion resistance

6.Superior mouldability and isotropy

Beryllium Copper Rod

Manhar Metal offer a wide assortment of Beryllium Copper Rod, Beryllium Copper strips, beryllium copper rods, beryllium copper sheet,copper beryllium rod, copper beryllium rods, copper beryllium strips, copper beryllium sheet. it is a metal alloy of copper and 0.5 to 2% beryllium, and sometimes with other alloying elements. Possessing significant metal working and operating performance qualities it is widely demanded by Engineering, Electrical and Electronics industries. Properties of Beryllium copper.

Specification:

Grade:

CuBe2-UNS C17200, CuBe2Pb-UNS C17300, CuCo2Be-UNS C17500, CuNi2Be-UNS.C17510, CuCo1Ni1Be

Test Certificate: MTC, Lab TC from Govt. Approved Lab with Third Party Inspection.

Features:

Dimensionally accurately

Corrosion Resistant

Good Conductivity

High tensile strength

Strong Resonance

Abrasion Property

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.