Tape Stretching Lines

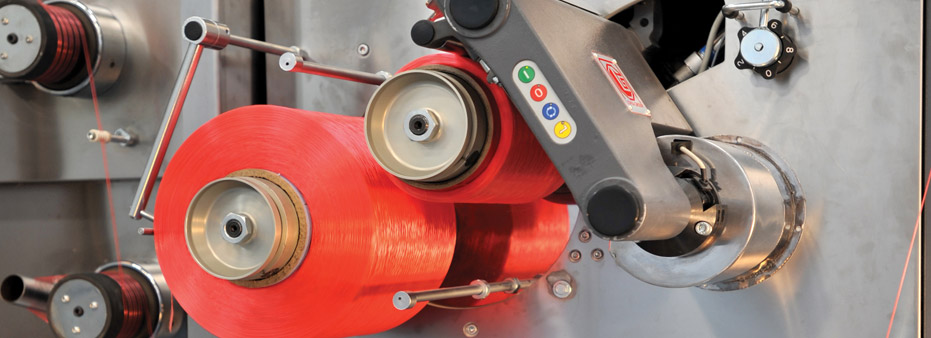

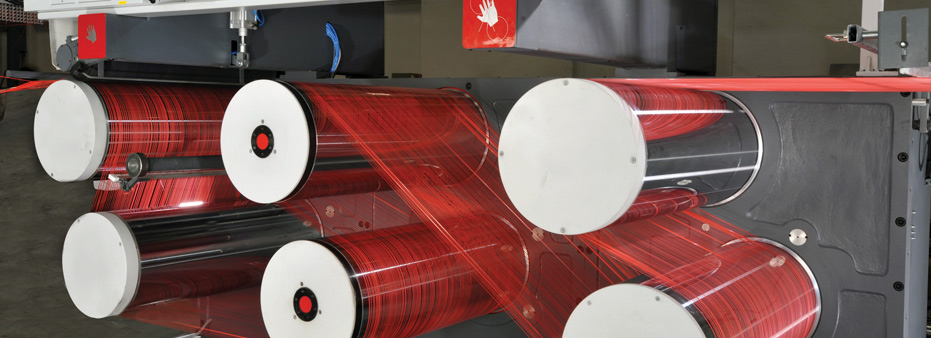

Lohia Corp Limited offers a comprehensive range of tape extrusion lines for producing high quality PP/HDPE tapes for a wide range of applications, such as – woven & knitted bags, jumbo bags - i.e. Flexible Intermediate Bulk Containers (FIBCs), carpet backings, tarpaulins, geo textiles, agro textiles, wrapping fabrics, ropes and twines.

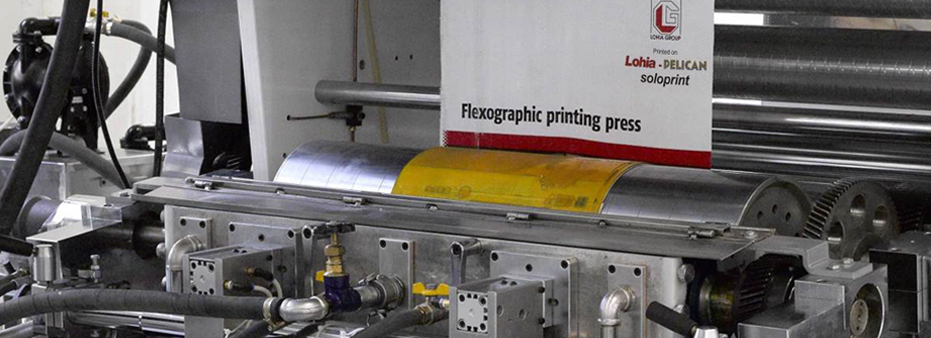

Our high speed tape stretching lines incorporate state-of-the-art technology and are calibrated to meet the highest international standards of performance and quality output. They are manufactured using the modular construction principle which offers flexibility for tailored adaptations for current needs as well for future expansions.

Backed by over three decades of design and production experience, these machines are built for maximum efficiency and promise higher profitability through minimum raw material and energy wastage.

Our tape extrusion lines come in two distinct series, LOREX & duotec. The LOREX series is based on the conventional single stage stretching system while the duotec series uses a unique double stage stretching system.