LODHA INTERNATIONAL LLP

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to LODHA INTERNATIONAL LLP

Automatic Single Head Bottle Screw Capping Machine

Single Head Bottle Screw Capping Machine Model: LI-BCS 1 is suitable for Round Bottles with maximum speed of 40 Bottles per minute. Single Head Bottle Screw Capping machine specially designed in Stainless Steel finish including machine M.S. frame structure with Stainless Steel Cladding/Enclosures.

Single Head Bottle Screw Capping Machine is equipped with Orientation type Cap Feeder for continues feeding of Cap for online operation on any liquid or powder filling line Single Head Bottle Screw Capping Machine suitable for various sizes of Bottles as well as Screw Cap with the help of change parts. Capping Machine is suitable for application in Pharmaceutical, Food, Pesticides, Chemical, Beverages, Liquor and other packaging industries having lower production requirement with automatic online operation.

SPECIAL FEATURES OF AUTOMATIC SINGLE HEAD BOTTLE SCREW CAPPING MACHINE

- No Bottle - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- Cap Feeder with Variable Speed System for feeding control of caps.

- Hopper can be completely dismantle for easy cleaning

- Various safety features including Clutch system to avoid Bottle Breakage or Jamming

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

Automatic Single Head Vial Cap Sealing Machine

Automatic Single Head Vial PP/Flip-Off Capping Machine Model: LI-VCS 1 is suitable for Round Vials with maximum speed of 40 Vials per minute. Single Head Vial Capping Machine specially designed in Stainless Steel finish including machine mild steel frame structure with stainless steel cladding/ Enclosures.

Single Head Vial Capping Machine is equipped with Vibratory Bowl Feeder for continues feeding of Cap for online operation on any liquid of powder filling line. Machine suitable for various sizes of Vials as well as Plain/ Flip-Off Cap with the help of change parts. Vial Capping Machine is suitable for application in Pharmaceutical industries having lower production requirement with automatic online operation.

SPECIAL FEATURES OF AUTOMATIC SINGLE HEAD VIAL CAP SEALING MACHINE

- No Vial - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- Cap Feeder with Variable Speed System for feeding control of caps.

- Hopper can be completely dis-mental for easy cleaning

- Various safety features including Clutch system to avoid Vial Breakage

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

Automatic Single Head Bottle R. O. P. P. Capping Machine

Single Head Bottle ROPP Cap Sealing Machine Model: LI-BCS 1R is suitable for ROPP capping of Round Bottles with speed of maximum 35 to 40 Bottles per minute depending on Bottle Diameter, Height and Cap diameter.

Single Head Bottle ROPP Capping Machine is specially constructed in Stainless Steel finish including M.S. frame structure with Stainless Steel Cladding/Enclosures.

ROPP Bottle Cap Sealing Machine is equipped with Orientation type Cap Feeder for continues feeding of Cap for online operation on any liquid or powder filling line. Machine suitable for various sizes of Bottles as well as ROPP Cap with the help of change parts. ROPP Capping Machine is suitable for application in Pharmaceutical, Food, Pesticides, Chemical, Beverages, Liquor and other packaging industries having lower production requirement with automatic online operation.

The needs of ROPP capping machine in modern world is increasing by leaps and bounds. ROPP capping machine works with oval, square, oval, and even rectangular packaging or bottles without any hassle. Capping machinery takes on several different forms depending on the type of cap used and to what degree the automation is required.

Bottle ROPP capping machine is used to boost the production without any complexity. The other names of such machines include ROPP capper machine and ROPP cap sealing machine. They all are now used for low to medium to high production facility.

THE BENEFITS OF ROPP CAP SEALING MACHINES

Capping machines can offer a number of benefits to the manufacturers. Here we list a few –

SECURE, RELIABLE, AND CONSISTENT PRODUCTION

Automated capping process renders repeatable actions of capping machines. Bottle’s cap is required to be tightened with the same force and fashion, the automated bottle ROPP capping machine delivers the exact amount of pressure to maintain the uniformity. This way, ROPP capper machines offer secure, reliable, and consistent seals.

QUICK PRODUCTION

With ROPP cap sealing machines, the production can be fastening as automatic cappers can fix the bottles and/or containers very fast. At the end of the day, the production is increased and so is the profit. Semi-automatic or manual capping of the bottles require a lot of time as the workers need to check the seals and ensure the tightening process.

WIDE RANGE OF PRODUCTIVITY

Most ROPP capper machines that run automatically have great versatility. In other words, the machines would handle a big range of various tasks i.e. cap tires and sizes, provided the tightening rule is the same. For instance, spindle cappers are utilized to tight screws on caps; an automated spindle capper, nevertheless, can handle all types of caps such as flat and sports. It can even trigger the sprayer.

EASY OPERATIONS

It is easy to handle and operate bottle ROPP capping machines and the operators don’t need special knowledge about them. The operators simply need to resupply the caps in bulk timely.

CUSTOMIZED INTEGRATION

Lastly, almost all automatic ROPP cap sealing machines can be integrated with other systems or existing package processes. In a case where power conveyors are present, the machines may just get integrated themselves with the existing production line and once they are set up fully, they can start producing quality services. Tailoring or customizing such bottle ROPP capping machines is possible and that is the reason, more and more manufacturers are now adapting the latest capping systems.

Whether it is a part of a utterly automatic package process or a step towards the same, automated capping machines help increasing the efficiency and productivity of the whole capping processes.

SPECIAL FEATURES OF ROPP CAPPING MACHINE:

- No Bottle - No Capping System

- No Bottle - Machine Stop System

- Machine construction in Stainless Steel Finish

- Cap Feeder with Variable Speed System for feeding control of caps.

- Hopper can be completely dismantling for easy cleaning

- Various safety features including Clutch system to avoid Bottle Breakage or Jamming

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

Automatic Pick And Place Bottle Screw Capping Machine

Automatic Pick & Place Bottle Screw Capping Machine is versatile designed with pneumatically operated gripper type pick n place with torque adjustment rotary plastic screw capping machine suitable for screw cap or snap/press fit caps.

Pick and Place Screw Capping machine in order to be used for different screw capping applications such as food & beverages, pharmaceutical, pesticides, distilleries, cosmetic, toiletries, personal care, chemical, oil etc. The Machine is often supplied with Orientations type Cap Feeder Elevator or Vibratory type Bowl Feeder depending on cap shape and size for continues feeding of Cap for online operation on any liquid of powder filling line.

LODHA’s capping machines are designed to secure almost any cap type onto a wide assortment of bottles. From Servo Based, Screw Caps, ROPP Caps, Crown Caps, Pick-n-Place, Snap/Press Fit, Aluminium Flip-Top Caps, Rubber Stopper Caps, Inner Plug, Twist- Off etc. Depending on cap type. The capping machine can operate from a touch screen and is capable of storing over multiple recipes. We provide you with the solution you need.

SPECIAL FEATURES:

- No Bottle - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- Cap Feeder with Variable Speed System for feeding control of caps.

- Hopper can be completely dismantled for easy cleaning

- Integrated Fault light And Alarm to Inform Operator Production Error

- Various safety features including Clutch system in feed worm to avoid Bottle Breakage or Jamming

- Machine Auto On / Off System, It Will Start Automatically Once Bottle Enter to the in-Feed Conveyor and Stop If Bottle Absence.

- Adjustable Conveyor Guide Rails to Accommodate with Different Products

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Fully Interlocked Guarding for Protection Safety

- Minimum Change over time

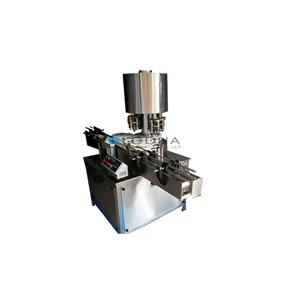

Automatic Four Head Bottle Screw Capping Machine

Automatic Four Head Bottle Screw Capping Machine, LI-BCS 4 is suitable for Round or different shape of Glass, Plastic or LDPE Bottles with maximum speed of 65 to 80 bottles per minute depending on Bottle Size and Cap Size.

Rotary Bottle Screw Capping Machine is constructed in Stainless Steel finish including machine M.S. frame structure and Stainless Steel Cladding. This Machine is suitable for applications in Pharmaceutical, Food, Pesticides, Cosmetic and Other Industries requiring higher production speed on automatic online operation.

Four Head Bottle Screw Capping Machine is equipped with Orientation type Cap Feeder or Vibratory type Bowl Feeder depending on cap shape and size for continues feeding of Cap for online operation on any liquid or powder filling line. Bottle Screw Capping Machine is suitable for various sizes of Bottles and Plastic Screw Cap with the help of suitable change parts.

SPECIAL FEATURES OF AUTOMATIC FOUR HEAD BOTTLE SCREW CAPPING MACHINE:

- Number of Head: Four

- Production Output: 65 to 80 bottles/min

- No Bottle - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- In feed and Exit Star Wheel with Overload Clutch System to avoid Bottle breakage

- Single Drive Synchronizing Total Operation of Star Wheel and Turret with Star Wheel

- Cap Feeder with Variable Speed System for feeding control of caps.

- Minimum Change Over and Setting time

- Hopper can be completely dismantle for easy cleaning

- Various safety features including Clutch system to avoid Bottle Breakage

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

Automatic Four Head Bottle R. O. P. P. Capping Machine

Automatic Four Head Bottle ROPP Capping Machine is suitable for Round or different shape of Glass, Plastic or LDPE Bottles with maximum speed of 65 to 80 bottles per minute depending on Bottle Size and Cap Size. Rotary Bottle ROPP Capping Machine is constructed in Stainless Steel finish including machine M.S. frame structure and Stainless-Steel Cladding. This Machine is suitable for applications in Pharmaceutical, Food, Pesticides, Cosmetic and Other Industries requiring higher production speed on automatic online operation.

Four Head ROPP Bottle Screw Capping Machine is equipped with Orientation type Cap Feeder or Vibratory type Bowl Feeder depending on cap shape and size for continues feeding of Cap for online operation on any liquid or powder filling line. Bottle ROPP Capping Machine is suitable for various sizes of Bottles and Plastic Screw Cap with the help of suitable change parts.

SPECIAL FEATURES OF AUTOMATIC FOUR HEAD BOTTLE ROPP CAPPING MACHINE:

- Number of Head: Four

- Production Output: 65 to 80 bottles/min

- No Bottle - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- In feed and Exit Star Wheel with Overload Clutch System to avoid Bottle breakage

- Single Drive Synchronizing Total Operation of Star Wheel and Turret with Star Wheel

- Cap Feeder with Variable Speed System for feeding control of caps.

- Minimum Change Over and Setting time

- Hopper can be completely dismantle for easy cleaning

- Various safety features including Clutch system to avoid Bottle Breakage

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

Automatic Four Head Vial Capping Machine

Automatic Four Head Rotary Vial Capping Machine Model: LI-VCS 4 for PP/Flip-Off Aluminium Cap. Machine is suitable for Round Vials with maximum speed of 120 Vials per minute depending on Vial Diameter, Vial Height and Cap Size. Specially Machine construction in Stainless Steel finish including machine M.S. frame structure with Stainless Steel Cladding/Enclosures. Vial Capping Machine can be used for Moulded or Tubular Glass Vials having Plain Aluminium Seals as well as Flipp-Off Seals with common change parts for both type of cap.

Machine with Unique Single Roller Sealing System ensures perfect sealing of vials with lower setting time. The Machine is equipped with Vibratory Bowl Feeder for continues feeding of Cap for online operation on any liquid of powder filling line. Machine suitable for various sizes of Vials as well as Plain / Flipp-Off Cap with the help of change parts. Capping Machine is suitable for application in Pharmaceutical and other industries requiring higher production speed on automatic online operation.

SPECIAL FEATURES OF AUTOMATIC FOUR HEAD VIAL CAPPING MACHINE

- No Vial - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- Infeed and Exit Star Wheel with Overload Clutch System to avoid vial breackage

- Single Drive Synchronizing Total Operation of Star Wheel and Turret with Star Wheel

- Cap Feeder with Variable Speed System for feeding control of caps.

- Minimum Change Over and Setting time

- Spring Loaded Unique Free Spinning Single Sealing Roller

- Hopper can be completely dismental for easy cleaning

- Various safety features including Clutch system to avoid Vial Breakage

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

Automatic Six Head Bottle Screw Capping Machine

Automatic Six Head Rotary Bottle Screw Capping Machine Model: LI-BCS 6, for Plastic Screw Capping Machine is suitable for Round or other shape of Glass, Plastic or LDPE Bottles with maximum speed of 80 Bottles per minute depending on Bottle Diameter, Bottle Height, Bottle Shape and Cap Size. Specially Machine construction in Stainless Steel finish including machine M.S. frame structure with Stainless Steel Cladding/Enclosures. The Capping Machine is ideal for application in Pharmaceutical, Food, Pesticides, Cosmetic & Other Industries.

The Machine is equipped with Orientation type Cap Feeder or Vibratory type Bowl Feeder depending on cap shape and size for continues feeding of Cap for online operation on any liquid of powder filling line. Machine suitable for various sizes of Bottles and Plastic Screw Cap with the help of change parts. Capping Machine is suitable for application in Pharmaceutical and other industries requiring higher production speed on automatic online operation.

SPECIAL FEATURES OF AUTOMATIC SIX HEAD BOTTLE SCREW CAPPING MACHINE:

- No Bottle - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- Infeed and Exit Star Wheel with Overload Clutch System to avoid Bottle breackage

- Single Drive Synchronizing Total Operation of Star Wheel and Turret with Star Wheel

- Cap Feeder with Variable Speed System for feeding control of caps.

- Minimum Change Over and Setting time

- Hopper can be completely dismantle for easy cleaning

- Various safety features including Clutch system to avoid Bottle Breakage

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

Automatic Six Head Bottle R. O. P. P. Capping Machine

Automatic Six Head Rotary Bottle Capping Machine Model: LI-BCS 6R, for ROPP Cap. Machine is suitable for Round or other shape of Glass, Plastic, PET, LDPE, HDPE Bottles with maximum speed of 120 Bottles per minute depending on Bottle Diameter, Bottle Height, Bottle Shape and Cap Size. Specially ROPP Capping Machine construction in Stainless Steel finish including machine M.S. frame structure with Stainless Steel Cladding/Enclosures. The Bottle Capping Machine is ideal for application in Pharmaceutical, Food, Pesticides, Cosmetic and Other Industries.

The ROPP Capping Machine is equipped with Orientation type Cap Feeder or Vibratory type Bowl Feeder depending on cap shape and size for continues feeding of Cap for online operation on any liquid of powder filling line. Bottle Capper Machine suitable for various sizes of Bottles and ROPP Cap with the help of change parts. ROPP Capper Machine is suitable for application in Pharmaceutical and other industries requiring higher production speed on automatic online operation.

SPECIAL FEATURES OF BOTTLE CAPPING MACHINE:

- No Bottle - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- Infeed and Exit Star Wheel with Overload Clutch System to avoid Bottle breackage

- Single Drive Synchronizing Total Operation of Star Wheel and Turret with Star Wheel

- Cap Feeder with Variable Speed System for feeding control of caps.

- Minimum Change Over and Setting time

- Hopper can be completely dismantle for easy cleaning

- Various safety features including Clutch system to avoid Bottle Breakage

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

Automatic Six Head Vial Cap Sealing Machine

Automatic Six Head Rotary Vial Capping Machine Model: LI-VCS 6, for PP/Flip-Off Aluminium Cap. Machine is suitable for Round Vials with maximum speed of 180 Vials per minute depending on Vial Diameter, Vial Height and Cap Size. Specially Machine construction in Stainless Steel finish including machine M.S. frame structure with Stainless Steel Cladding/Enclosures. Machine can be used for Moulded or Tubular Glass Vials having Plain Aluminium Seals as well as Flip-Off Seals with common change parts for both type of cap.

Machine with Unique Single Roller Sealing System ensures perfect sealing of vials with lower setting time. The Machine is equipped with Vibratory Bowl Feeder for continues feeding of Cap for online operation on any liquid of powder filling line. Machine suitable for various sizes of Vials as well as Plain / Flip-Off Cap with the help of change parts. Capping Machine is suitable for application in Pharmaceutical and other industries requiring higher production speed on automatic online operation.

SPECIAL FEATURES OF AUTOMATIC SIX HEAD VIAL CAP SEALING MACHINE:

- No Vial - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- Infeed and Exit Star Wheel with Overload Clutch System to avoid vial breackage

- Single Drive Synchronizing Total Operation of Star Wheel and Turret with Star Wheel

- Cap Feeder with Variable Speed System for feeding control of caps.

- Minimum Change Over and Setting time

- Spring Loaded Unique Free Spinning Single Sealing Roller

- Hopper can be completely dismental for easy cleaning

- Various safety features including Clutch system to avoid Vial Breakage

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

Automatic Eight Head Bottle Screw Capping Machine

Automatic Eight Head Rotary Bottle Screw Capping Machine, Model: LI-BCS 8 for Plastic Screw Cap. Machine is suitable for Round or different shapes bottles of Glass/ PET/ Plastic/HDPE or with maximum speed of 160 Bottles per minute depending on Bottle Diameter, Bottle Height, Bottle Shape and Cap Size. Specially Machine construction in Stainless Steel finish including machine M.S. frame structure with Stainless Steel Cladding/Enclosures. The Capping Machine is ideal for application in Pharmaceutical, Food, Pesticides, Cosmetic & Other Industries.

The Machine is equipped with Orientations type Cap Feeder or Vibratory type Bowl Feeder depending on cap shape and size for continues feeding of Cap for online operation on any liquid of powder filling line. Machine suitable for various sizes of Bottles and ROPP Cap with the help of change parts. Capping Machine is suitable for application in Pharmaceutical and other industries requiring higher production speed on automatic online operation.

SPECIAL FEATURES OF AUTOMATIC EIGHT HEAD BOTTLE SCREW CAPPING MACHINE

- No Bottle - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- Infeed and Exit Star Wheel with Overload Clutch System to avoid Bottle breakage

- Single Drive Synchronizing Total Operation of Star Wheel and Turret with Star Wheel

- Cap Feeder with Variable Speed System for feeding control of caps.

- Minimum Change Over and Setting time

- Hopper can be completely dismantle for easy cleaning

- Various safety features including Clutch system to avoid Bottle Breakage

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

Automatic Eight Head Bottle R. O. P. P. Capping Machine

Automatic Eight Head Rotary Bottle Capping Machine, LI-BCS 8R is suitable for Round or different shapes of Glass, PET, LDPE, HDPE, Plastic Bottles with maximum speed of 160 Bottles per minute depending on Bottle Diameter, Bottle Height, Bottle Shape and Cap Size. Specially Machine construction in Stainless Steel finish including machine M.S. frame structure with Stainless Steel Cladding/Enclosures. The Capping Machine is ideal for application in Pharmaceutical, Food, Pesticides, Cosmetic & Other Industries.

The Machine is equipped with Orientation type Cap Feeder or Vibratory type Bowl Feeder depending on cap shape and size for continues feeding of Cap for online operation on any liquid of powder filling line. Machine suitable for various sizes of Bottles and ROPP Cap with the help of change parts. Capping Machine is suitable for application in Pharmaceutical and other industries requiring higher production speed on automatic online operation.

SPECIAL FEATURES:

- No Bottle - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- Infeed and Exit Star Wheel with Overload Clutch System to avoid Bottle breakage

- Single Drive Synchronizing Total Operation of Star Wheel and Turret with Star Wheel

- Cap Feeder with Variable Speed System for feeding control of caps.

- Minimum Change Over and Setting time

- Hopper can be completely dismantle for easy cleaning

- Various safety features including Clutch system to avoid Bottle Breakage

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

Automatic Eight Head Vial Cap Sealing Machine

Automatic Eight Head Rotary Vial Capping Machine, Model: LI-VCS 8 for PP/Flip-Off Aluminium Cap. Machine is suitable for Round Vials with maximum speed of 240 Vials per minute depending on Vial Diameter, Vial Height and Cap Size. Specially Machine construction in Stainless Steel finish including machine M.S. frame structure with Stainless Steel Cladding/Enclosures. Machine can be used for Moulded or Tubular Glass Vials having Plain Aluminium Seals as well as Flipp-Off Seals with common change parts for both type of cap.

Machine with Unique Single Roller Sealing System ensures perfect sealing of vials with lower setting time. The Machine is equipped with Vibratory Bowl Feeder for continues feeding of Cap for online operation on any liquid of powder filling line. Machine suitable for various sizes of Vials as well as Plain / Flipp-Off Cap with the help of change parts. Capping Machine is suitable for application in Pharmaceutical and other industries requiring higher production speed on automatic online operation.

SPECIAL FEATURES:

- No Vial - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- Infeed and Exit Star Wheel with Overload Clutch System to avoid vial breakage

- Single Drive Synchronizing Total Operation of Star Wheel and Turret with Star Wheel

- Cap Feeder with Variable Speed System for feeding control of caps.

- Minimum Change Over and Setting time

- Spring Loaded Unique Free Spinning Single Sealing Roller

- Hopper can be completely dismental for easy cleaning

- Various safety features including Clutch system to avoid Vial Breakage

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

Automatic Linear Bottle Capping Machine

Automatic Linear Bottle Capping Machine Model: LI-LBC 150

is suitable for capping the round of irregular shapes or bottles (Glass, Plastic, PET, LDPE, HDPE) with the maximum speed of 150 bottles per minute. The speed also depends on bottle diameter, bottle design, bottle shape and cap size. This automatic linear capping machine has special linear design with no change parts system for change in size of the bottle. Moreover, it also has totally synchronized front and back bottle holding belt with stabilizing and pressing belt system.

This linear capper machine is built with stainless steel finishing and MS frame structure. It is ideal for application in various industries such as Food, Pharmaceutical, Pesticides, Cosmetic and other industries. It comes with a very user friendly operation to handle different types of bottles. This linear capping machine comes with Orientation type Cap Feeder or Vibratory type Bowl Feeder for continuous feeding of measuring cup. It is suitable for application in industries with high production requirement.

The Automatic linear bottle capping machine is one of consistency, reliability, and security, and its largest benefits are included in the fact that it provides a repeatable action provision. This versatility offered by the machine can increase the number of bottles that can be sealed during the production activity. A well-maintained automatic linear capping machine takes care of the speed as well as the consistency in sealing. The unique feature of this capper is that it can integrate easily with any packaging line and eliminate any loss of product. It makes business and production a pleasurable experience and can be custom-built as per needs. Efficiency and productivity along with reduced costs along the entire packaging process make it a delightful buy.

SALIENT FEATURES OF AUTOMATIC LINEAR BOTTLE CAPPING MACHINE:

- Auto Stop System For No Bottle/Cap Situation

- Constructed in Stainless Steel Finish

- No Change Parts System for changes in Bottle Size

- Single Drive Synchronized Complete Operation (Bottle Feeding, Holding Belt and Pressing Belt System)

- Cap Feeder with Varying Speed System.

- Minimum Change Over time

- Minimum Setting time

- Complete dismantling of Hopper for easy cleaning

ADDITIONAL FEATURES OF AUTOMATIC LINEAR BOTTLE CAPPER MACHINE:

- Equipped with PLC – HMI Interface

- Cap Feeder Elevator

- Safety Cabinet with Toughened Glass or Acrylic

High Speed Bottle Capping Machine

High Speed Bottle Capping Machine, Model: LI-BCS 8H for Plastic Screw Cap. Machine is suitable for Round or other shape of Glass/Plastic/PET/HDPE or LDPE Bottles with maximum speed of 160 Bottles per minute depending on Bottle Diameter, Bottle Height, Bottle Shape and Cap Size. Specially Machine construction in Stainless Steel finish including machine M.S. frame structure with Stainless Steel Cladding/Enclosures. The Capping Machine is ideal for application in Pharmaceutical, Food, Pesticides, Cosmetic & Other Industries.

The Machine is equipped with Orientations type Cap Feeder or Vibratory type Bowl Feeder depending on cap shape and size for continues feeding of Cap for online operation on any liquid of powder filling line. Machine suitable for various sizes of Bottles and ROPP Cap with the help of change parts. Capping Machine is suitable for application in Pharmaceutical and other industries requiring higher production speed on automatic online operation.

SPECIAL FEATURES

- No Bottle - No Cap System

- No Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- Infeed and Exit Star Wheel with Overload Clutch System to avoid Bottle breakage

- Single Drive Synchronizing Total Operation of Star Wheel and Turret with Star Wheel

- Cap Feeder with Variable Speed System for feeding control of caps.

- Minimum Change Over and Setting time

- Hopper can be completely dismantle for easy cleaning

- Various safety features including Clutch system to avoid Bottle Breakage

- Single Drive synchronizing operation of Conveyor and Star Wheel

- Minimum Change over time

Vial Capping Machine

High Speed Vial Screw Capping Machine Model: LI-VCSH

is suitable for round vials with the maximum speed of 240 vials per minute. The speed also depends on Vial height, Vial diameter and Cap size. The high speed vial screw capping machine is built with stainless steel finishing including MS frame structure. It can also be used for tubular or moulded Glass Vials with Plain Aluminium Seals and Flip-Off Seals.

LI-VCSH Vial Screw Capper

comes with special single roller selling system that allows perfect sealing of vials with lower setting time. It comes with continuous Vibratory Bowl Feeder for cap feeding in any powder of liquid filling line. This high speed vial screw capping machine is suitable for different vials sizes as and plain or flip-off caps. It is suitable for applications in industries with high production requirement. This advanced vial capping machine is extremely versatile and offers high tech features like ‘No vial – No Capping’ and ‘No Cap – No Capping’. It is also equipped with a clutch system to prevent vial breakage. Moreover, the hopper of this high speed vial screw capping machine can be completely dismantled for easy cleaning. It also has spring loaded free spinning sealing rollers to prevent the damage and provide flexibility. This high quality machine is widely used in the pharmaceutical industry because of its excellent performance.

SPECIAL FEATURES OF HIGH SPEED VIAL CAPPING MACHINE:

- Automatic System : No Vial - No Capping

- Automatic System :No Cap – No Capping

- Constructed in stainless steel

- Infeed and Exit Star Wheel for automatic stoppage in case of overloading or jamming

- VFD Speed System equipped Cap Feeder for feeding control

- Unique Spring Loaded Free Spinning Single Sealing Roller

- Complete dismantling of Hopper for easy cleaning

- Clutch system to prevent Vial Breakage

- Stainless Steel parts for long life

- Single Motor synchronized Conveyor, Star Wheels and Platform Turret

- Equipped with inbuilt Pulse Counter

- Automatic System : Container Overturn – Machine Stop

- Spring loaded free spinning Sealing Rollers to damage prevention and flexibility

- Single Ratchet setting for quick change over

- Unique Sealing Rollers for high-quality skirting and sealing

ADVANTAGES OF VIAL CAPPING MACHINE:

Vial capping machine is an integral part of packaging industry because of the high speed and accuracy. It is very difficult to achieve the amount of production, by capping with hands, which can be easily achieved with screw capping machine. Vial capper is very versatile as it is used in various industries such as beverages, pharmaceuticals, cosmetics, chemicals and dairy products. Screw capping machine has enabled industries to achieve high production to meet high requirement of their products.

Semi Automatic Bottle Capping Machine

Semi-Automatic Screw Capping Machine Model LI-SC is suitable for applying Cap on various type and shape of Vials and bottles with maximum speed of 40 Vials/ Bottles per minute depending on Vial/ Bottle Size and type of Cap to be capping. Screw Capping Machine suitable for applying PP Cap, ROPP aluminium cap or plastic screw cap with the help of change parts /capping head. This machine is useful for small scale production units for medium scale production requirements.

Semi Automatic Screw Capping Machine with built in Table/Stand for trouble free operation.

SPECIAL FEATURES:

- Compact machine model & multipurpose use

- No Vial/Bottle - No Capping System

- Machine construction in SS304 material

- Suitable for all type of PP Cap, ROPP Alu. Cap and Plastic Screw Cap

- Heavy Duty Machine structure

- Low noise & Less power consumption

- Cap Sealing Pressure varied according to different size of caps.

- Adjustable gauge provided for different height of bottles.

Automatic Measuring Cup Placement Machine

Automatic Linear Measuring Cup Placement Machine Model: LI-MCP 150 is suitable for Round or irregular shapes of Glass, Plastic, PET, LDPE, HDPE Bottles with maximum speed of 150 Bottles per minute depending on Bottle Diameter, Bottle Height, Bottle Shape and Measuring Cup / Cap Size.

Machine with special Linear Design with No Change Parts system for Change in Bottle Size. Machine with Totally Synchronized Front and Back Bottle Holding Belt with Top Stabilizing and Pressing Belt System.

Specially Machine construction in Stainless Steel finish including machine M.S. frame structure with Stainless Steel Cladding/Enclosures. Machine is ideal for application in Pharmaceutical, Food, Pesticides, Cosmetic & Other Industries. Machine with user friendly operation to handle various type and size of bottles.

The Machine is equipped with Orientation type Cap Feeder or Vibratory type Bowl Feeder depending on cap shape and size for continues feeding of Measuring Cup / Cap for online operation on any liquid of powder filling line. Machine suitable for various sizes of Bottles and Measuring Cup / Cap with the help of change parts. Machine is suitable for application in Pharmaceutical and other industries requiring higher production speed on automatic online operation.

SALIENT FEATURES:

- No Bottle - No Cup / Cap System

- No Bottle / Cap - Machine Stop System

- Machine construction in Stainless Steel Finish

- Linear Bottle Movement with No Change Parts System for change in Bottle Size

- Single Drive Synchronizing Total Operation of Bottle Feeding, Bottle Holding Belt and Top Holding / Pressing Belt System

- Cap Feeder with Variable Speed System for feeding control of caps.

- Minimum Change Over and Setting time

- Hopper can be completely dismantling for easy cleaning

- Minimum Change over time

ADDITIONAL FEATURES:

- PLC – HMI Interface based automation

- Cap Feeder Elevator

- Toughened Glass or Acrylic Safety Cabinet for Machine Model

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.