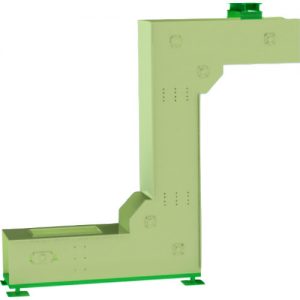

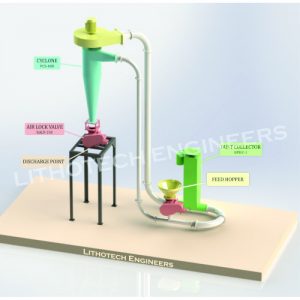

Dump Booth

This equipment ensures proper feeding mechanism with controlled feed rate and dust free atmosphere. Raw materials which are normally in gunny bags are emptied on the grid inside the dump booth. Around 3 bags can be unloaded simultaneously. There is a hood above which if connected to the suction line would collect the dust generated during empting the bags. The material slides in the screw conveyor mounted below it which conveys the materials at uniform feed rate. The speed is controlled through VFD depending upon the application. The simultaneous feeding of different spices ensures blending prior to grinding. This reduces the blending time during final blending operation.