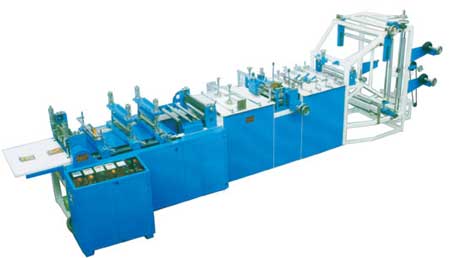

Automatic Side Sealing Bag Making Machine

Specifications :

Microprocessor controlled roll feeding

Main AC frequency motor with AC frequency drive

Unwinder with AC frequency motor

Conveyer nylon belts driven through AC frequency motor

Digital counter with batch preset including alarm & totalizer

Automatic system to adjust bag length

Color mark scanner including registration attachment

Steel Table for stacking of bags having magnetic stands

Automatic positional stop

Control panel housing with Electricals & Electronics

Center trimming arrangement

Side cutting attachment

Temperature controller and indicating lamps