KOTHARI PHARMA TECHNOLOGIES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KOTHARI PHARMA TECHNOLOGIES P.LTD.

Fluid Bed Dryer

Very versatile process equipment.

• Fully automatic operation based on PLC control.

• Minimum handling and more hygienic.

• Top Mounted telescopic cylinder for auto bag shaking.

• Clamp type bottom mesh for container.

• Capacity available from 2.5 kgs. To 500 kgs.

• MOC SS 304 / 316 / 316L.

• cGMP with documentation.

Inline Mixer Cum Microniser

Model available IMM – 100 to IMM – 3000

• High speed stator and rotor construction

• Available for both batch and continuous production.

• Inbuilt mechanical seal.

• High degree of sanitary finish.

• Meets GMP and FDA norms.

• MOC SS 316 / 316L.

• cGMP with documentation.

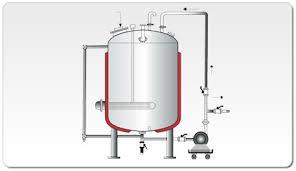

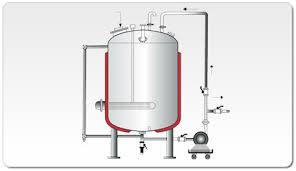

D. W. Storage Tank

Available capacity 100 ltrs. To 10000 ltrs.

• Material of construction SS 316 / 316

• Direct heater. Strip heater or steam jacketed / coil.

• Provided digital temperature controller / indicator.

• Circulation pump for uniform temperature.

• Automatic level controller to be connected to MCDP.

• Horizontal /Vertical execution as per site requirement.

• All joints nozzles are triclover.

Automatic Capsule Filling Machine

ACF is fully automatic encapsulation machine. Encapsulation is the filling of empty capsule with the desired drug. It is done using tamping principle. In this the powder formulation is formed into a slug, which is delivered to the body of capsules. This machine can fills hard gelatin capsules with powder, granules, and pellets.

The machine is designed to give varied output range of 6,000, 25,000, 40,000, 90,000 & 150,000 capsules per hour with high filling accuracy & can accommodate capsule size from ‘0’ to ‘5’

This machine is productivity enhancing machine, which is handled by one operator.

Capsule Filling Machine Semi Automatic

SALIENT FEATURES:

cGMP Model.

PLC based machine.

A special design for easy changeover of different size capsules within 20 minutes.

Filled weight accuracy within +3%.

Simple operation, operator training can be done in 15 minutes.

Automatic declutching of loader to minimize operator’s attention and ensures optimum production.

Simple structure and low malfunction, easy to maintain and easy to clean.

Quick changeover of parts greatly reduces downtime of the machine during product change.

Low noise & maintenance.

Automatic Capsule Loading Machine

To enhance production line output

CLM with CFM M/C

Output: 90 Trays / hour

Line Output:

- CLM with 1 CFM M/C up to 9,000 capsules / hrs with 2 operators

- CLM with 2 CFM M/C up to 18,000 capsules / hrs with 3 operators

- CLM with 3 CFM M/C up to 27,000 capsules / hrs with 4 operators

Automatic Ointment And Cream Mfg Plant

Application

Pharmaceuticals: Creams, Gels, Sterile & Non Sterile Ointments and Biotech products.

Cosmetics: Cold Creams, Hair Dye Cream, Conditioners, Lotions, Gels, Mascara make-up, Shampoo, Toothpaste.

Technical feature:

Main Vessel:

• Choice of various type of anchor design.

• Homogeniser (option) – Top Entry, side Entry, Bottom Entry with circulation facility.

• Hydraulic lid lifting for fast & easy cleaning of top dish & vessel.

• Load Cell for fast & accurate measuring system.

• Flexible product transfer pipe & fitting in case of load cell & hydraulic lifting.

• VFD for Anchor agitators to vary the RPM.

• VFD for Homogeniser to vary RPM.

• Specially Design drive assembly.

Wax vessel:

• Open top with top Entry agitator Cowl disc type or paddle with Slow Speed Anchor.

• Close top with top/bottom entry agitator Cowl disc type or propeller type stirrer.

Water Vessel:

• Open top with top entry propeller stirrer

• Close top with bottom or top entry propeller

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.