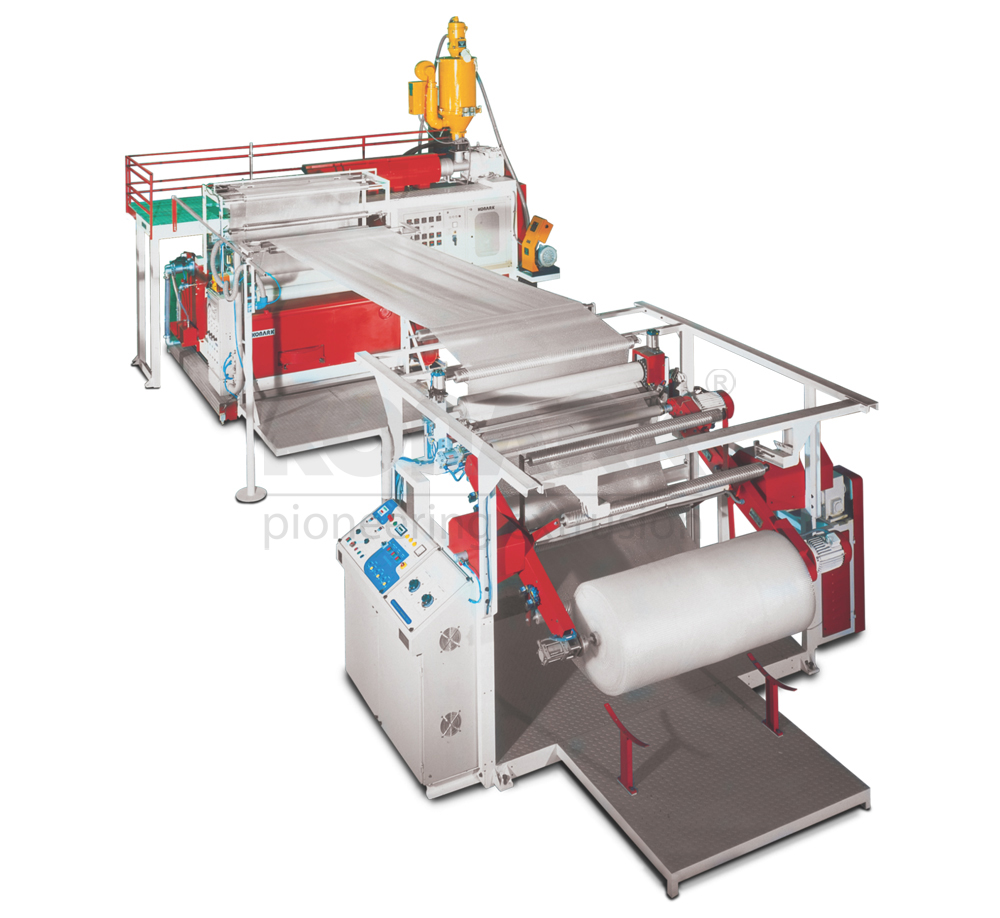

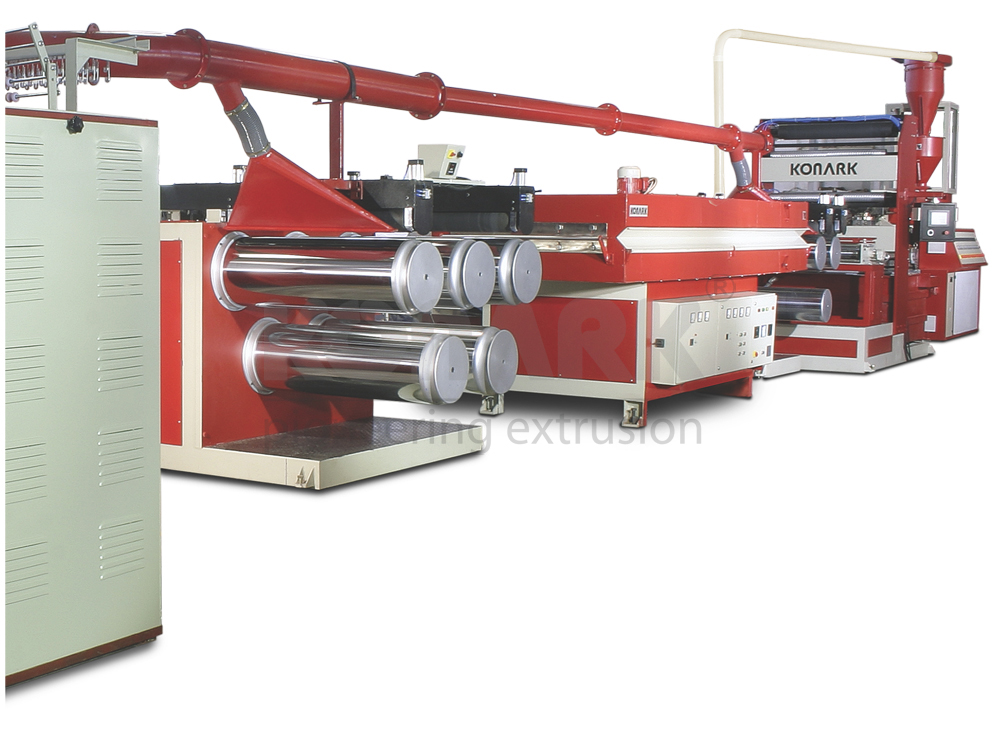

Features

Optimum product costing due to high productivity with less power consumption

Nitrided screw and barrel made out from special nitro alloy steel for long life and trouble free operations

Helical gear box with inbuilt thrust bearing

Manual lever type screen changer

Uniquely designed double lip 'T' die ensuring uniform flow distribution

PLC controlled turret type automatic winding system

Microprocessor based PID temperature controller

Synchronization of all AC motors

Auto hopper loader with dryer