KAY INTERNATIONAL LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KAY INTERNATIONAL LTD.

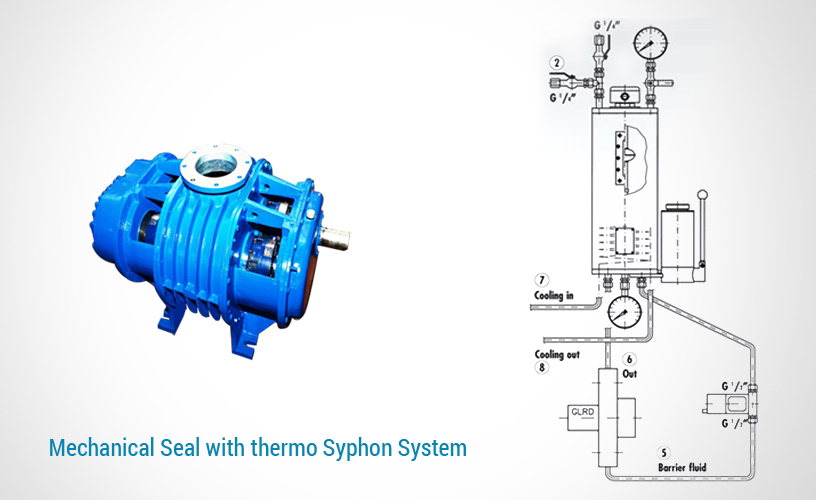

Kay Mechanical Vacuum Boosters

IMPORTANT FEATURES:

High Vacuum upto 0.001 mbar or better with suitable backup vacuum pump.

Kay Mechanical Vacuum Boosters latest Technology by bypass type design.

International design compliance to API/ISO/BS/CE certified standards.

Advance technology Double sealing system for leak proof design.

Oil & Water free dry running operation makes clean operation .

Kay Dry Screw Vacuum Pumps

IMPORTANT FEATURES:

High Vacuum upto 0.01 mbar or better.

International design compliance to API/ISO/BS/CE certified standards.

Advance technology Double sealing system for leak proof design.

Oil & Water free dry running operation makes clean operation .

Suitable for pumping toxic, corrosive and condensable gas by special material of construction.

Kay Oil Lubricated Vacuum Pump

IMPORTANT FEATURES:

Environmental – clean exhaust, no pollution.

High vacuum, strong pumping.

Advanced German technology. Suitable for one to one replacement of local or imported, similar pumps with lower cost and higher performance.

Equipped with check valve and oil anti-suck back device. (Inlet with check valve to prevent vacuum oil back into the system. No oil loss owing to the integrated oil return line)

continuous trouble free working for more than 3,000 hours .

Kay Liquid And Water Ring Vacuum Pump

TECHANICAL DATA

CAPACITY : 30 TO 30000 m3/hr.

ULTIMATE VACUUM : 33 mbar.

IMPORTANT FEATURES:

These Pumps are designed to handle gas, water and vapour.

Used in industries like paper, sugar, chemicals, waste oil re-refining, food processing etc for vacuum filtration, vacuum distillation.

Water ring pumps are the only alternative to steam jet ejectors for handling large amounts of wet vapor or liquid & small amount of solids as the pump operates in a liquid environment (Water).

Suitable for pumping toxic, corrosive and condensable gas by special material of construction.

It is ideal for wet processes such as filtration, drying, condenser exhausting & distillation.

Relatively low power consumption and low maintenance.

Low cost, minimum noise / vibration.

Kay Double Stage Oil Sealed Vacuum Pump

IMPORTANT FEATURES:

Excellent Ultimate Vacuum and pumping speed with high performance.

Improved oil anti- suck back system to protect the vacuum pump in the event of sudden stop.

Low Noise and Vibrations

Strong and constant pressure based oil circulation system to protect the pump.

Easy maintenance, Compact Design and High Reliability.

Convenient gas ballast valve control enabling open and shut down of gas ballast valve at ease while operational.

Kay Dry Running Vacuum Pump

IMPORTANT FEATURES:

Completely Dry Operation.

Self-lubricating (Graphite) rotary vanes.

Dry Operations enables to make environment clean.

High Vacuum Level in continuous operation.

Effective Heat Discharge, the state of the art and precise manufacturing.

Application Serves: Handling & Lifting, Clamping Device, Pick & Place, Packaging, R&D Laboratory, Food & Plastic Industry etc.

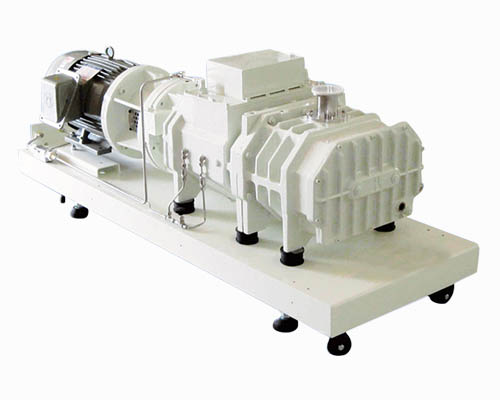

Kay Vacuum Systems And Packages

IMPORTANT FEATURES:

High Vacuum upto 0.001 mbar or better with suitable backup vacuum pump.

International design compliance to API/ISO/BS/CE certified standards.

Advance technology Double sealing system for leak proof design.

Oil & Water free dry running operation makes clean vacuum.

Suitable for pumping toxic, corrosive and condensable gas by special material of construction.

No metal to metal contact between lobes and Casing ensures long Booster life.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.