KAPILANSH DHATU UDYOG P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KAPILANSH DHATU UDYOG P.LTD.

Cast Iron Socket And Spigot Pressure Pipes

We are proud to introduce ourselves as one of the eminent manufacturer of Cast Iron Fittings, which are capable to survive the high pressure with longer durability and better performance. These Cast Iron Fittings are manufactured using quality material, sourced from the trusted vendors of the industry.

As Cast Iron Fittings providers we serve clients from varied sectors and have an umbrella experience of various requirements of clients. Our entire range of Cast Iron Fittings is manufactured by most experienced engineers who design the pipe fittings with Cast Iron that are applicable in different industries. These Cast Iron Fittings are appreciated for high durability, efficient performance, easy maintenance and superior functioning. Our range of fittings is as follows: 1. Cast Iron Flange Fittings - As per IS: 1538 – 80mm to 300mm dia. 2. Cast Iron Socketted (Lead / Drip Seal Joint) Fittings – As per IS: 1538 – 80mm to 300mm dia. 3. Cast Iron Mechanical Joint Fittings – As per IS: 13382 – 80mm to 300mm dia. 4. Customised Fittings – As per client’s requirement. Cast Iron Fittings Application C I Flange Fittings: The cast iron flange fittings are suitable for use with Cast / Ductile Iron Flanged Pipes. C I Socketted (Lead / Drip Seal Joint) Fittings: The Lead Joint / Drip Seal Joint fittings are suitable for use with Cast / Ductile Iron Socket & Spigot Pipes. C I Mechanical Joint Fittings: The Mechanical Joint fittings are used with Cast Iron & Ductile Iron Socket & Spigot Pipes.

Cast Iron Soil Pipes And Fittings

“Kapilansh Centrifugal” Soil Pipes & Fittings (IS 3989) “Kapilansh” the name that has become synonymous with Centrifugally Cast Pressure Pipes in India, offers Centrifugally Cast (Spun) Iron Spigot and Socket Soil, Waste, Ventilating and Rain Water Pipes, fittings & Accessories confirming to IS: 3989:2009 for all your Drainage System needs i.e.

• Soil & Waste Discharge System

• Rain Water System

• Ventilation System

“Kapilansh” with their expertise in manufacturing Cast Iron Pressure Pipes, utilized “De Lavaud Process” for manufacturing “Kapilansh Centrifugal” Pipes. The superior Quality Assurance and control measures ensure you get only the best piping for the drainage system.

Advantages of “Kapilansh Centrifugal” drainage system

• Assured quality as per specification.

• Superior corrosion resistance to soil, waste water & chemicals.

• Also superior Atmospheric weathering & corrosion resistance.

• Low thermal expansion.

• High compressive strength & beam load bearing capacity.

• Smooth inner surfaces giving better flow characteristics.

• Environment friendly as fully recyclable.

• Better Aesthetic look.

• Engineered for Skyscrapers.

Cast Iron Earthing Pipes

Over the years, mankind has made some truly remarkable discoveries, and one extremely important lesson has been the importance of grounding electrical currents. Electricity has provided countless benefits to people, but it still remains one of the most deadly elements in human society, and unless you are grounding your electrical systems you are taking a rather large risk.

The following is a look at some of the main reasons why grounding electrical currents is so important.

1. Protection of Electrical System from Overload Current.

2. Provide least resistance path to Leakage / Stray / Overload Current between the System and Earth.

3. Protect human life from getting electrocuted.

4. Give least resistance path to the Lightening to pass to ground.

5. With the support of Soil (Earth) if not suitable then it is made suitable by reconditioning with Back

Fill Compound and Cover with Earth Pit Cover. To prevent contamination at earth pit top.

We are a leading manufacturer of Treated Earthing System made by Centrifugal Casting Process including attachments like single flange, hot dip galvanized clamp, Cast Iron Funnel with casted mesh, alternate hole & taper cut along with accessories like “KapitrodeTM” “Back Fill Compound and Earth Pit Covers” in various sizes as per drawing specification for grounding Electrical Systems.

Our capability has been assessed by the various contractors, corporate and Electricity boards. We are regularly supplying to Power Generation, Transmission & Distribution companies i.e MSETCL, GETCO, KPTCL, MPPTCL, UGVCL, MSPGCL etc, Industries i.e. Chemical, Cement, Mining, Petroleum – Refineries & Outlets, Pharma, Steel, Sugar, Textile etc, Solar Energy, Winds Energy & Bio Energy Plants, Projects i.e. Civic Structure, Commercial & Residential from last Two decades.

Advantages / Benefits of using Cast Iron Earthing System - “KapitrodeTM”

• High surface area of contact

• Durable and Reliable

• Corrosion Resistance

• Excellent Connectivity & Conductivity

• Uniform Current Dissipation

• Easy Installation

• Environmental Friendly

• Cost Effective

In view of the above we would like to request your goodself to kindly consider “KapitrodeTM” - Cast Iron Earthing System for grounding electrical currents in your esteemed Organization. If you require any other clarification kindly feel free to write to us.

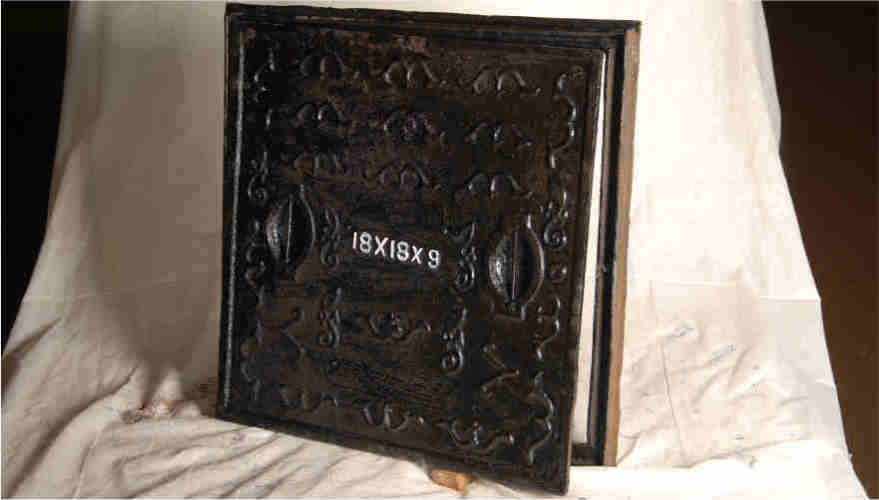

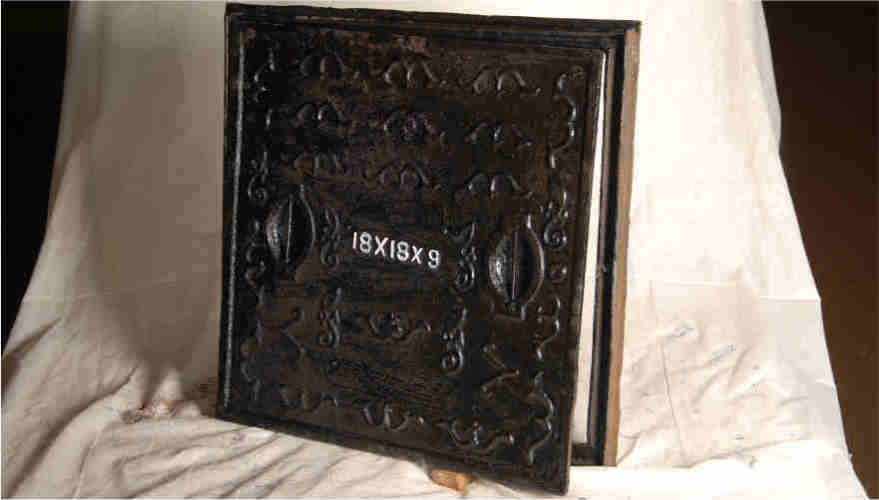

Manhole Covers

We have a recently forayed into manufacturing of ductile iron manhole covers Gratings & Frames. These are manufactured as per BS EN-124 standard and are safe because of high strength and low weight. They have frames for better security and anti-skid checkered designs for total safety. Our manhole covers and gratings can bear heavy duty traffic, have keyholes for easy lifting and larger open area for water drainage.

Additionally as per your requirements we can include locking arrangements too. If new patterns are to be developed we can do that in 6 weeks. Your logo can also be imprinted on these products.

Back Fill Compound

Our advanced range of electrodes come with a Kapitrode™ compounds suitable for unique requirement of our customers these are considered to be the ideal back fill material filled for an earthing system. On adding water, this compound is easily compacted and has the capability of absorbing moisture up to fourteen times its dry volume. It improves conductivity and having quality of long time capacity of retention or absorption of moisture, high conductivity and non corrosive. ASK FOR PRICE Completely fulfilling the purpose of back-filling in electrodes, Kapitrode™ earthing chemical compound reduces the soil resistance and further creates a low resistance zone around the electrode. Previously, salt & charcoal were used as filling material in conventional earthing but it use to corrode the earthing after sometime but with the latest developments in earthing, we have introduced a specially developed, natural and Eco friendly material with improved properties. Kapitrode™ earthing chemical compound has the capacity to absorb & retain moisture around the electrode thus protects the entire earthing system.

Features

• Does not dissolve in to soil or water

• Do not washes away with time

• Installed dry or can be mixed with water for the formation of slurry for

vertical or horizontal applications

Advantages

Kapitrode™ earthing chemical compound has following advantages over conventional backfilling compounds:

• Maintenance free with no requirement of hydration or salt replacement

• Environmentally Neutral or we can say PH Neutral. It poses no negative impact on environment

• No salts present in it and it will not contaminate the soil

• Able to maintain low grounding resistance with minimum fluctuation for long period of time

• Compressive Strength and Low Shrinkage

• Low & Stable resistivity

• Water Absorption

• Economically viable

Application

Widely used in earthing systems for backfilling in between electrodes

Alloy Cast Iron Pipes

Alloy Cast Iron Pipes (Also known as Abrasion Resistant Pipes)

We manufacture “Alloy Cast Iron Pipes” (Also Known as Abrasion Resistant Pipe) by centrifugally casting process which provides uniform wall thickness and mass density. These pipes are specifically formulated to maximize hardness and resistance to wear, minimizing abrasive failures and are the best carrier for conveying of slurry, fly ash, bottom ash and economizer ash

Features

• Material: Centrifugally Cast, low Chrome iron alloyr

• Hardness: 280-320 BHN (Alloy -1), 400-550 BHN (Alloy – 2)

• Internal Diameter: 100mm to 300mm

• Wall Thickness: 10.5mm to 16mm (depending on size)

•Pipe Ends: Plain / Flange Joints

•Length: Standard length is 5.4 mtr. Custom lengths are also available to suit customer needs

Advantages

• Alloy Cast Iron for superior abrasion resistance

• Centrifugally Cast process eliminates blow holes, slag and sand inclusions resulting high quality, abrasion resistant product

• Centrifugal casting process produces an interior surface that progressively resists wear over time

• On-site rotation of pipe changes wear location and extends service life

• Resistance to oxidation (upto 1200°F) is ideal for high temperature applications such as economizer ash conveying

• High temperature and impact resistant material which is ideal for ash handling system

• Plain Ends provides easy installation and replacement with sleeve couplings

Alloy Cast Iron Pipes Testing at Works

Chemical Composition Test – Conducted at works by Wet Analysis Process. Mechanical Test – Mechanical tests shall be carried out, during manufacture. Tests for every four hours of production shall be conducted. The results obtained shall be taken to represent all the pipes of all sizes made during that period.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.