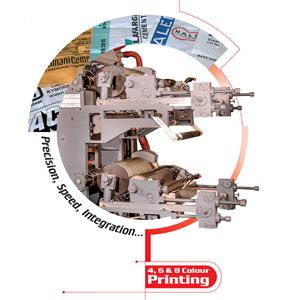

Printing Machines

High speed, PLC base 4/6/8 color flexo printing machine for Woven Sack having inline Corona Treatment, micro perforation, twist gusseting, cutting/winding system, for HDPE / PP laminated and un-laminated woven fabrics.

FEATURES:

- Turret Unwinder with Online Manual Splicing

- Specially designed Micrometric adjustment system provided at each Printing Station to have fine pressure from Anilox Roll to Printing Drum and from Printing Drum to the final product (Fabric). This will improve the better sharpness of Printing.

- Individual Gearbox system consists of hardened and ground oil dipped gears with the inbuilt planetary arrangement at each printing station. This increases the sturdiness of the machine which reduces maintenance and downtime.

- Online print registration adjustment provided in that gearbox for easy operation.

- Easy changeover for a change of direction of printing with the help of same gearbox system is also incorporated.

- Infeed and outfeed driven nip roll system to maintain constant tension of fabric for proper Print registration. It will not elongate the fabric or loosen the fabric between printing station.

- Anilox and Ink Rubber Rolls are of special design. This prevents splashing and scattering of Ink at higher operating speeds.

- Access to each printing station for ease of monitoring and cleaning.

- Operator Friendly and space-saving vertical gusseting unit.

- Control panel with PLC