Products & Services

Special Precision Fasteners

Our partner fasteners manufacturing facility in India is an ISO 9001:2008 Certified Company

We offer a wide range of Bolts, Screws, Nuts, Washters, Studs and Automobile Fasteners in:

- Alloy Steel

- Mild Steel

- Stainless Steel

- High Tensile

- Copper

- Brass

Having application in:

- Automobiles

- Electricals & Electronics

- Machine Tool

- Railways

- Defense

- Power

- Etc.

Continuous adherence of stringent norms conforming to international standards make our products at par with the best in world.

Precision C. N. C. Machining

The CNC Machining process is more precise than manual machining, and can be repeated in exactly the same manner over and over again.

Because of the precision possible with CNC Machining, this process can produce complex shapes that would be almost impossible to achieve with manual machining.

CNC Machining is used in the production of many complex three-dimensional shapes.

We offer following CNC operations through our hitech manufacturing facilities in India:

- CNC Turning

- CNC Milling

- CNC Grinding

Materials for CNC Machining:

- Steel / Stainless Steel / Steel Alloys

- Aluminum / Aluminum Alloys

- Brass

- Bronze

- Copper

- Titanium

- Die Castings

- Plastics

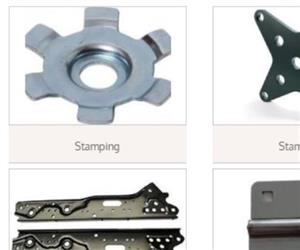

Stamping

Metal Stamping is a process that use dies to transform flat metal sheets into shapes.

Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining.

Stamping is either a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or a multiple stage process.

We offer following CNC operations through our hitech manufacturing facilities in India:

- Tool & Die Making

- Stamping

- Machining

- Assembly

Rubber And Plastic Molding

Injection molding is a manufacturing process accomplished by forcing raw, uncured rubber into a heated mold using a reciprocating screw. The material is formed and cured under heat and pressure, then removed to cool as a custom shape.

Compression molding uses a pre-measured amount of raw rubber material that is placed into a heated open lower mold cavity. The top cavity is then forced closed, causing the raw material to flow through the shape of the mold.

In transfer molding, rubber is measured, heated and forced into chamber. A plunger is used to force the material into the mold using a system of runners and channels to thoroughly fill the closed mold. The mold is heated to cure the raw material.

Precision Traub Components

|

Precision Grinding Components

|

Power Press Component

|