JEETMULL JAICHANDALL P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to JEETMULL JAICHANDALL P.LTD.

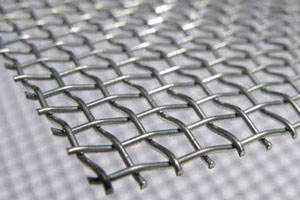

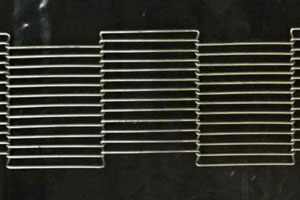

Balanced Weave Conveyor Belt

The balanced weave conveyor belt is an economical belt and most widely used in various industries with loose or containerized products like food processing, ceramic, glass, metal working etc. These belts are driven by friction and is the optimal choice for friction driven conveyors.The basic features of the balanced weave conveyor belts include flat surface, minimal maintenance, good flexibility, resistance to distortion, economical weave, high tensile strength and excellent strength-to-weight ratio. Balanced weave belts can be manufactured to match new or existing pinrolls and are available in a wide range of specifications. Balance weave wire mesh conveyor belts are available in High Carbon Steel, Galvanized, 304 Stainless steel, 316 Stainless steel, 314 Stainless steel etc. The balanced weave conveyor belt is used for cooker and fryer conveyor belts, drying and cooling conveyor belts, annealing oven conveyor belts and more.

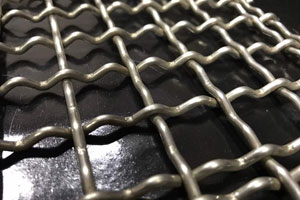

Compound Balanced Weave Conveyor Belt

The compound balance weave conveyor belts provides better tracking and baking ans is hence excellent for bakery applications. This kind of belts contain a mass of alternate right and left hand spirals compressed beyond their normal hinging position to produce a dense mat like weave. The weave is so close in compound balanced weave conveyor belt that they are used in applications which includes carrying of small parts like nut bolts, screws, nail etc.

Honeycomb Conveyor Belt

The Honeycomb Conveyor belts are also known as the Flat Wire Belts and are made using ross rods and a flat metal strip. This belt is an ideal choice for the applications which requires both durability and an open belt design whilst maintaining a flat carrying surface. It is put to use in various industries like food processing, freezing, baking, drying, painting, bread production system, product handling, cleaning etc. The basic features of Honeycomb Conveyor belts include flat surface, easy to clean and maintain, flat carrying surface, positive sprocket drive, high strength to weight ratio and quick repair.

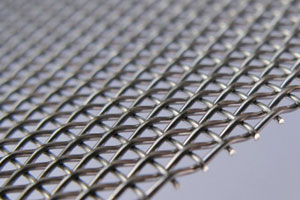

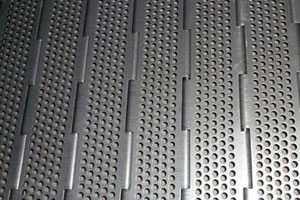

Flattened Wire Conveyor Belt

The Flat wire Conveyor Belts are the most economical straight running belts available and are an assembly of automatically formed precision flat wire pickets. It helps in increasing the productivity, cut the cost and improve the quality of the product. What put the flattened wire conveyor belts to huge demand in the market are the features like no slip, positive drive, easy to clean, clean-in-place design, very low belt mass etc. It is usually made using 302 stainless steel. The yfurther provide faster drainage of liquids, free air circulation and ease of cleaning.

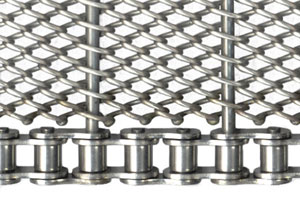

Chain Conveyor Belt

The Chain Conveyor belts designed by Jeetmull are made in accordance to the industry norms and standards. Theyare used majorly in industries such as heat treating, forging, foundry, food processing, snack food, baking, ceramics, glass, automotive and more. They are also suitable for washing, loading, assembly and conveying lines. The Chain Conveyor belts manufactured by the company is rust free, has accurate dimension and also offers rugged construction.

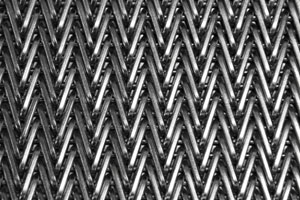

Chain Link Type Conveyor Belt

The Chain Link Type Conveyor belt manufactured by Jeetmull is available with a mesh of large or small openings and is quite suitable for the light duty use. This simple and functional wire belt design is made by interweaving successive spiral coils to create an open mesh. The Chain Link type conveyor belt can also be used as a collapsible screen and has excellent load capacity. It has minimum stress build up at the intersections and is quite economic and light weighted. This belt is used majorly for chain drive belting, drying and cooling applications, protective barriers etc.

Rod Conveyor Belt

The Rod Conveyor Belt from Jeetmull are simply combined with rods and chains link or U-shaped edges. Although they have quite a simple structure yet the belt is solid and rigid. It is put in use for various applications. The Rod Conveyor Belt can withstand very high or low product temperature, have low elongation and contraction, superior adhesion levels and linear strength. As a result of the high grade raw material used in the making of the product, it ensures a long lifespan and is quite easy to install and replace. The typical belt styles include interwoven loops, flat wire, straight rods and balanced weave.

Enrober Conveyor Belt

The Enrober Conveyor Belts are made of stainless steel. It is available as belts in single loop or with doubled loop edges. Made from pre-shaped wires this is applied in straight and curved conveyors. The Enrober Conveyor Belt are easy to install, wear and tear proof and requires less maintenance. It has a sturdy construction and is corrosion and abrasion resistant. It is used in various industry like snacks, fish, breads, chocolate and more.

Link Conveyor Belt

The Link Conveyor Belt is highly viable to be used in rigorous engineering processes like die-casting, forging etc as it has a high load capacity. It joins in a very short period of time and requires a very small installation time as well. It is a simple design, yet very functional where spiral coils are interwoven to create an open mesh. The link conveyor belt offers an economic and light weight solution for low load conveying applications. The typical application of this conveyor belt is in industries like transport, cooling, drainage, lift guards, industrial furnaces etc.

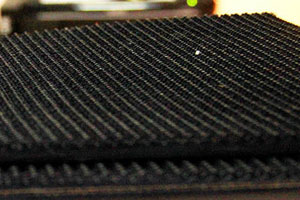

Rubber Conveyor Belt

The Rubber Conveyor Belts re used in the industries where bulk material handling is required. It is made using high grade raw materials like nylon, rubber, rough top and PVC coated materials, which guarantees superiority, durability, and easy functioning. With high working efficiency, long lasting and robust construction, the rubber conveyor belts have high tensile strength, strong adhesion to rubber and excellent elasticity. They are used for transportation for middle and long distances.

Nylon Conveyor Belt

The Nylon Conveyor Belts are made using high quality raw material. With high tensile strength, durability and high quality material these nylon conveyor belts are extremely reliable and has high capacity range. These are dimensionally accurate, requires low maintenance and have good trough ability as well. They have high impact and are very flexible. These are put to application in industries like mining, metallurgical, architectural industry, cement plants, stone crusher and ceramic plants etc.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.