INSIGHT ENGINEERING SYSTEMS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to INSIGHT ENGINEERING SYSTEMS P.LTD.

Six Stage Cleaning Machine

Chlorinated solvents were the choice solvent till thet were proven hazardous to human health and environment. Some chlorinated solvents are suspected to cause cancer (Carcinogenic ) over prolonged exposure . Being hazardous to health their usage has come under intense investigation from pollution control and health authorities. This has lead to a shift to alternative cleaning technology based on aqueous solvents.

Carburetor Cleaning Machine

Carburator cleaning machine is specially designed to clean the fine oil passages of carburetor.

To achieve a very high through put and reduced cycle time

The components are passed individually in a pallet and the oil passage is

cleaned by oriented spray.

To achieve this with a low cycle time in each station one side is cleaned.

Cleaning is done at very high pressure.

Oil Pump Body Cleaning Machine

Description / Specification of Oil Pump Body Cleaning Machine

We are involved in offering a wide range of Oil Pump Body Cleaning Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Oil Pump Body Cleaning Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

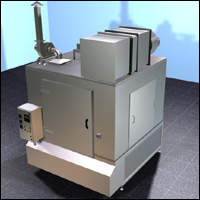

High Pressure Washing Machine

Multi Cylinder Pumps Housing

The high pressure wahsing machine is designed to clean pump housings or similar component.

Deep holes require the spray jet to reach up to the required depth.

Very High pressure cleaning. Both oriented spray and gross spray.

Here the job is loaded in the chamber.

A set of long oscillating lance jet will enter and exit the deep holes and clean the same.

Cleaning is followed by good rinsing.

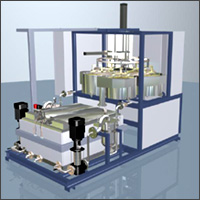

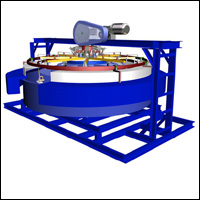

Tin Coating Plant

Tin coating plant with Transporter type transfer mechanism

Tin coating plant is specially designed to facilitate best Tin coating of parts. Flexibility to have loading and unloading at the same end or opposite ends. The system can have variable process time and also the jobs can have a rotation in the process liquids.

This machine is best to achieve Tin coating requirements.

Kfie Video Of Chromating

Surface Treatment Plant With Transporter Type Transfer Mechanism

This is a trivalent chromating system for components. Chromating is a surface conversion process of aluminum to achieve better corrosion resistance. The trivalent chrome process is more environment friendly than the conventional hexa-valent chrome process.

This is a large surface treatment plant with 22 tanks, 3 nos of transporters, exhaust system, Scrubber etc.

Chromeplating Plant

Description / Specification of Chromeplating Plant

We are involved in offering a wide range of Chromeplating Plant to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Chromeplating Plant. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

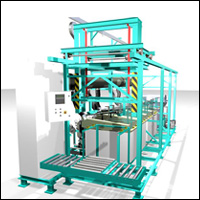

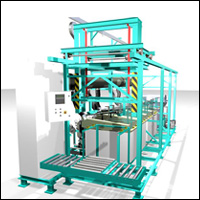

Double Line Piston Cleaning Machine

Cleaning System with Pick and Place Mechanism

The machine is specially designed to clean the piston or similar components

This is a single piece flow machine

Loading and unloading at the same end

High through put and reduced cycle time

Piston is loaded on the fixture can be manual or auto.

Piston grove and pin holes are cleaned by oriented spray.

Cleaning is done at 5-6 kg pressure.

Ultrasonic cleaning is added for fine cleaning

Cleaning is followed by good rinsing

Cleaning is followed by air drying from top, side and bottom of the piston.

This type is specially designed to facilitate best cleaning of parts going to the final assembly.

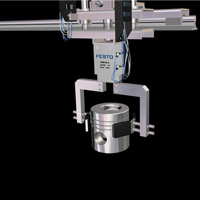

Nozzle Cleaning Machine

Fuel Injection Nozzle Cleaning Machine

The machine is specially designed to clean the fine oil passages of Nozzles.

To achieve a very high through put and reduced cycle time

The components are passed as a set of 4 nos. in a pallet and the oil passage are cleaned by oriented spray.

Ultrasonic cleaning is added for fine cleaning

Cleaning is done at very high pressure.

Cleaning is followed by good rinsing

Cleaning is followed by hot air and vacuum drying.

The system is designed for line automation.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.